60 mil HDPE Liner Landfill Impermeable Geomembrane

HDPE (High-Density Polyethylene) geomembranes are a widely used impermeable liner material in landfill applications. At a thickness of 60 mil (1.5 mm), these geomembranes provide a highly effective barrier against the migration of liquids and gases, making them an essential component in the design and construction of modern landfills.

The 60 mil HDPE liner geomembrane is a durable and long-lasting solution that is resistant to chemical degradation, UV exposure, and physical damage, ensuring the integrity of the landfill's containment system for an extended period. The material's high tensile strength and low permeability make it an ideal choice for preventing the leakage of contaminated leachate into the surrounding environment, while also controlling the release of landfill gas.

HDPE (High-Density Polyethylene) liner is a widely used geomembrane material for landfill applications. These liners serve as an impermeable barrier, preventing the migration of leachate, which is the liquid that percolates through the waste in a landfill, from seeping into the surrounding soil and groundwater. The 60 mil thickness refers to the thickness of the HDPE liner, which is typically expressed in mils (1 mil = 0.001 inches).

HDPE liners are chosen for their excellent chemical resistance, durability, and long-term performance. They are able to withstand the harsh environmental conditions found in landfills, including exposure to a variety of waste types, UV radiation, and mechanical stress from the overlying waste and cover materials. The impermeable nature of HDPE liners ensures that the leachate is contained within the landfill, reducing the risk of contamination to the surrounding environment.

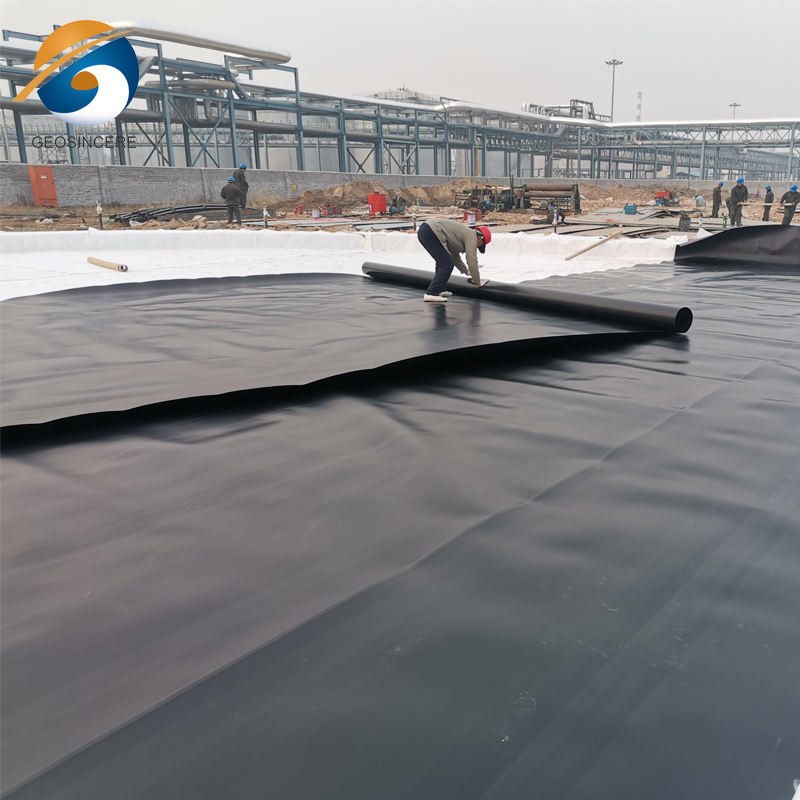

The installation of a 60 mil HDPE liner is a critical component of a well-designed landfill system, as it provides a reliable and long-lasting barrier to prevent the uncontrolled release of leachate. This helps to protect the local ecosystem, groundwater resources, and overall environmental quality in the vicinity of the landfill.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

60 mil HDPE Liner Landfill Impermeable Geomembrane Features

1. Thickness: The 60 mil thickness provides a robust and durable barrier to prevent the passage of liquids and gases. The increased thickness enhances the liner's mechanical strength and resistance to punctures or tears.

2. Impermeability: HDPE liners are highly impermeable, with an extremely low permeability to water and other liquids. This prevents the migration of leachate from the landfill into the surrounding soil and groundwater.

3. Chemical Resistance: HDPE is resistant to a wide range of chemicals, including acids, bases, and organic solvents commonly found in landfill environments. This ensures the long-term integrity of the liner.

4. UV Resistance: HDPE liners are resistant to degradation from exposure to ultraviolet (UV) radiation, allowing them to maintain their physical and mechanical properties over time.

5. Durability: HDPE liners are highly durable and can withstand the significant loads and stresses imposed by the overlying waste and cover materials in a landfill. This ensures the liner's long-term performance.

6. Ease of Installation: HDPE liners are relatively easy to install, with reliable welding techniques to create seamless connections and ensure the continuity of the barrier.

7. Cost-Effectiveness: HDPE liners are a cost-effective solution for landfill lining compared to some other geomembrane materials, making them a popular choice for landfill construction and management.

These features collectively contribute to the reliable and long-lasting performance of a 60 mil HDPE liner in a landfill environment, effectively containing the leachate and protecting the surrounding ecosystem.

Applications of 60 mil HDPE Liner Landfill Impermeable Geomembrane

1. Landfill Lining:

- HDPE liners are commonly used as the primary liner system in the bottom of landfills to prevent the migration of leachate into the surrounding soil and groundwater.

- They are installed as a critical component of the landfill's composite liner system, which also includes other layers such as compacted soil or a geosynthetic clay liner.

2. Leachate Collection and Containment:

- The HDPE liner acts as an impermeable barrier, ensuring that leachate generated within the landfill is collected and contained within the landfill's leachate management system.

- This prevents the uncontrolled release of leachate and potential contamination of the environment.

3. Landfill Capping and Final Cover:

- HDPE liners can also be used as a component of the final cover or cap system for a closed or decommissioned landfill.

- The liner helps to limit the infiltration of rainwater and the release of landfill gases, further enhancing the long-term containment of the waste.

4. Waste Containment Facilities:

- HDPE liners are not limited to landfills and can be used in other waste containment facilities, such as hazardous waste disposal sites, surface impoundments, and waste piles.

- The liner's impermeability and chemical resistance make it suitable for containing a wide range of waste materials.

5. Pond and Reservoir Liners:

- In addition to landfill applications, 60 mil HDPE liners can be used to line ponds, reservoirs, and other water containment structures to prevent seepage and leakage.

The versatility and proven performance of 60 mil HDPE liners have made them a widely adopted solution for effectively containing and managing waste, water, and other liquid materials in various environmental and industrial applications.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrana and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembana, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrana research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembrana and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembrana and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembrana and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!