HDPE Uniaxial Plastic Geogrid for Road Construction

HDPE uniaxial plastic geogrid is a type of geosynthetic material commonly used in road construction projects. It is designed to enhance the performance and durability of road pavements by providing reinforcement and improving load distribution.

The primary function of HDPE uniaxial plastic geogrid in road construction is to reinforce the pavement structure. It distributes the load from traffic and reduces stress on the road layers, thereby minimizing deformation, rutting, and cracking. The unidirectional strength of the geogrid allows it to efficiently handle tensile forces along the length of the grid.The geogrid enhances load transfer within the road structure by effectively distributing the load to a wider area. It reduces localized stress concentrations and improves the load-bearing capacity of the pavement, contributing to its long-term performance.

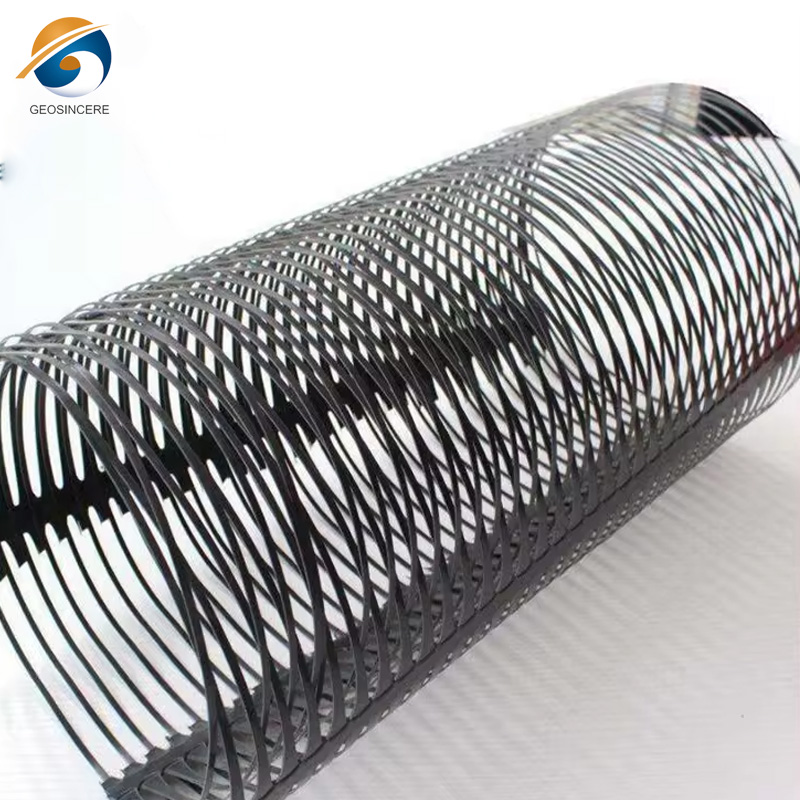

HDPE uniaxial plastic geogrid is a widely used geosynthetic material in road construction projects. It offers several features and benefits that contribute to the performance and durability of road pavements. HDPE (High-Density Polyethylene) is a robust and chemically resistant plastic material. It provides excellent tensile strength, stiffness, and durability, making it suitable for demanding road construction applications.HDPE uniaxial plastic geogrid is designed with a unidirectional strength along the length of the grid. It typically consists of longitudinal ribs or bars that provide primary reinforcement, while transverse connectors or bars serve to stabilize the grid structure.

The primary purpose of HDPE uniaxial plastic geogrid in road construction is to reinforce the pavement structure. It effectively distributes the traffic load, mitigates stress, and reduces deformation, rutting, and cracking in the road layers. HDPE uniaxial plastic geogrid facilitates the transfer of loads within the road structure. By efficiently distributing the load, it minimizes localized stress concentrations and improves the load-bearing capacity of the pavement. This enhances the overall performance and extends the service life of the road.HDPE uniaxial plastic geogrid interacts with the surrounding soil and aggregate layers in the road pavement. It interlocks with the soil particles, creating a stable composite system. This interaction enhances the stability, improves shear resistance, and controls differential settlement of the road layers.

The use of HDPE uniaxial plastic geogrid in road construction offers several advantages. It improves the structural integrity and stability of the pavement, reduces the required thickness of road layers, enhances resistance to rutting and cracking, and provides long-term performance even in challenging soil conditions. Additionally, it can expedite construction processes and reduce maintenance costs.

Parameter

Properties | BGUG 25 | BGUG 35 | BGUG 50 | BGUG 80 | BGUG 110 | BGUG 120 | BGUG 150 | |

Width(mm) | 1100 | |||||||

Length /roll (m) | 50 | |||||||

Yield strength ≥kN/M | HDPE | 25 | 35 | 50 | 80 | 110 | 120 | 150 |

PP | 25 | 35 | 50 | 80 | 110 | 120 | 150 | |

Elongation | HDPE (%) | 11-16 | ||||||

PP≤ (%) | 10 | |||||||

Strength at 2% elongation ≥kN/M | HDPE | 6 | 9 | 10 | 23 | 30 | 35 | 46 |

PP | 7 | 10 | 12 | 26 | 32 | 38 | 48 | |

Strength at 5% elongation ≥kN/M | HDPE | 12 | 18 | 25 | 44 | 60 | 70 | 87 |

PP | 14 | 20 | 28 | 48 | 64 | 75 | 93 | |

HDPE Uniaxial Plastic Geogrid for Road Construction Features

HDPE (High-Density Polyethylene) uniaxial plastic geogrids for road construction offer several features that make them suitable for enhancing the performance and durability of road pavements.

High Tensile Strength

Uniaxial Design

Durability

Lightweight

Enhances Stability

Improved Load Distribution

Easy Installation

Cost-Effectiveness

Applications of HDPE Uniaxial Plastic Geogrid for Road Construction

HDPE uniaxial plastic geogrids find various applications in road construction projects. They are used to enhance the performance and durability of road pavements by providing reinforcement and improving load distribution. Here are some common applications of HDPE uniaxial plastic geogrids in road construction:

Subgrade Stabilization: HDPE uniaxial plastic geogrids are used to stabilize weak or problematic subgrade soils. They are placed between the subgrade and base course to improve the load-bearing capacity, reduce subgrade settlement, and enhance the overall stability of the pavement structure.

Base Course Reinforcement: HDPE uniaxial plastic geogrids are often incorporated within the base course layer of road pavements. They provide reinforcement by distributing loads and reducing the stresses imposed on the base course. This reinforcement helps to prevent cracking, rutting, and deformation in the pavement.

Overlay and Rehabilitation: In road rehabilitation projects, HDPE uniaxial plastic geogrids are used in overlay applications. They are placed between the existing pavement and the new asphalt overlay to improve the bond between the layers, reduce reflective cracking, and enhance the overall structural integrity of the road.

Slope Stabilization: HDPE uniaxial plastic geogrids can be utilized for slope stabilization in road construction. They are installed along slopes or embankments to reinforce the soil and prevent erosion, slope failures, and movement. The geogrids provide tensile strength and stability to the slope, improving its overall safety.

Retaining Wall Construction: HDPE uniaxial plastic geogrids are commonly used in the construction of retaining walls for road projects. They are incorporated within the backfill soil behind the wall to enhance the soil-reinforcement interaction and improve the stability and load-bearing capacity of the wall.

Load Transfer Platforms: HDPE uniaxial plastic geogrids are employed in load transfer platforms, where they are placed between pavement joints or slabs. They help to distribute loads, reduce joint movement, and prevent faulting, thereby enhancing the performance and longevity of the pavement.

Erosion Control: HDPE uniaxial plastic geogrids can be used in erosion control applications along roadways. They are installed in areas prone to erosion, such as ditches or channel linings, to stabilize the soil, prevent erosion, and maintain the integrity of the road infrastructure.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!