Steel-Plastic Weld Geogrid for Slope Stability

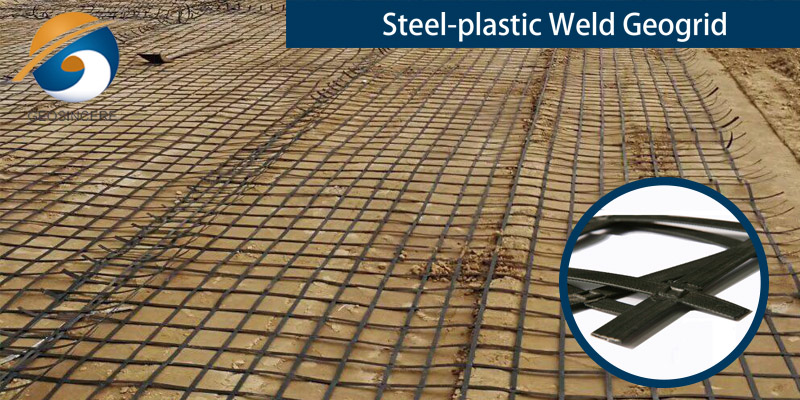

Steel-plastic weld geogrids are geosynthetic materials specifically designed for slope stability applications. They combine the strength and durability of steel with the flexibility and corrosion resistance of plastic. These geogrids are used to reinforce slopes and prevent soil erosion, providing enhanced stability and long-term performance.

Steel-plastic weld geogrids serve as a reinforcement element in slope stability applications. They are placed within the soil mass to improve its tensile strength, prevent sliding, and enhance overall stability. The geogrids work by redistributing the forces acting on the slope and increasing the soil's resistance to shear and tensile stresses.The plastic coating on steel-plastic weld geogrids provides excellent corrosion resistance, protecting the steel core from environmental factors such as moisture and chemical exposure. This corrosion resistance ensures the long-term durability and performance of the geogrid, even in harsh conditions.

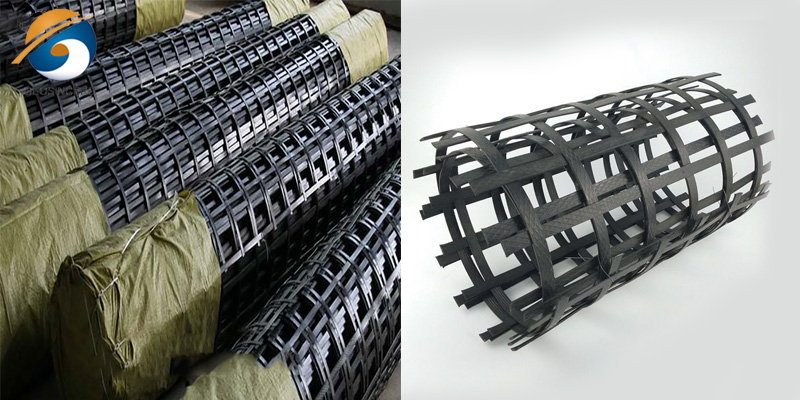

Steel-plastic weld geogrids are advanced geosynthetic materials used for slope stability applications. They combine the strength of steel with the flexibility and corrosion resistance of plastic to provide effective reinforcement and stabilization of slopes. Steel-plastic weld geogrids consist of high-strength steel wires or strands that are coated or encased in a protective polymer layer, typically made of polyethylene (PE) or polypropylene (PP). The steel core provides high tensile strength, while the plastic coating protects against corrosion and enhances durability.The steel wires or strands are welded at junction points to form a grid-like structure. This welding process ensures a robust connection between the steel elements, providing structural integrity and the ability to distribute loads effectively.

Steel-plastic weld geogrids have excellent tensile strength, enabling them to resist the forces exerted on slopes. They can withstand high loads and redistribute these forces, reducing stress concentrations and enhancing slope stability.The plastic coating on the steel wires provides corrosion resistance, protecting the steel from degradation due to moisture and chemical exposure. This corrosion resistance is crucial for long-term performance and durability in slope stability applications.The plastic coating on the geogrids adds flexibility, allowing them to conform to the shape of the slope and accommodate differential settlement. The combination of steel and plastic results in a durable geogrid that can withstand environmental factors and maintain its performance over time.Steel-plastic weld geogrids interact with the surrounding soil, creating a soil-geogrid composite system. The geogrids interlock with the soil particles, improving shear resistance and preventing soil movement. This interaction enhances slope stability and reduces the risk of slope failure.

Steel-plastic weld geogrids provide reinforcement to slopes, preventing soil erosion, landslides, and slope failures. They improve the overall stability of the slope by distributing the forces acting on it and increasing its resistance to shear stresses.Steel-plastic weld geogrids offer a cost-effective solution for slope stability compared to traditional methods such as soil nailing or retaining walls. They require less excavation, reduce the need for extensive earthworks, and offer long-term performance and durability, resulting in cost savings over the lifespan of the slope.

Parameter

Properties | BSD 30-30 | BSD 40-40 | BSD 50-50 | BSD 60-60 | BSD 80-80 | BSD 100-100 | BSD 150-150 |

Longitudinal Tensile Strength kN/m | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

Horizontal Tensile Strength kN/m | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

Elongation Rate % | ≤2 | ||||||

Tensile Strength at 1% Strain kN/m | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

Limit peel force at welded bonded ponded point kN/m | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

Limit peel force at welded bonded ponded point N | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 |

Steel-Plastic Weld Geogrid for Slope Stability Features

Steel-plastic weld geogrids for slope stability offer several key features that make them effective in reinforcing and stabilizing slopes. Here are some of the notable features of steel-plastic weld geogrids:

High Tensile Strength

Corrosion Resistance

Flexibility

Soil Interaction

Durability

Load Distribution

Cost-effectiveness

Provide Long-term Performance

Applications of Steel-Plastic Weld Geogrid for Slope Stability

Steel-plastic weld geogrids are widely used in slope stability applications to reinforce and stabilize slopes. They offer numerous benefits and can be applied in various scenarios. Here are some common applications of steel-plastic weld geogrids for slope stability:

Steep Slope Stabilization: Steel-plastic weld geogrids are effective in stabilizing steep slopes, such as highway embankments, railway cuttings, or construction sites with significant grade changes. They provide reinforcement to the soil, reducing the risk of slope failure and erosion.

Retaining Wall Reinforcement: Steel-plastic weld geogrids can be used to reinforce retaining walls and enhance their stability. By installing the geogrids within the soil backfill behind the wall, they provide additional tensile strength and prevent the soil from sliding.

Landslide Mitigation: In areas prone to landslides, steel-plastic weld geogrids can be employed to stabilize the slopes and mitigate the risk of slope failures. The geogrids help to distribute the forces exerted on the slope, improving its overall stability and reducing the potential for landslides.

Cut Slope Stabilization: Cut slopes created during excavation or road construction are vulnerable to erosion and instability. Steel-plastic weld geogrids can be installed within the cut slope to reinforce the soil and prevent slope failure, ensuring the long-term stability of the slope.

Erosion Control: Steel-plastic weld geogrids are effective in controlling erosion on slopes by preventing soil loss and promoting vegetation growth. They stabilize the soil, protect against surface erosion caused by rainfall or runoff, and provide a stable surface for vegetation to establish.

Reinforced Earth Structures: Steel-plastic weld geogrids are commonly used in the construction of reinforced earth structures, such as mechanically stabilized earth (MSE) walls or slopes. They provide reinforcement to the soil mass, allowing for the construction of structurally stable and durable earth structures.

Slope Reinforcement in Mining Operations: In mining operations, where steep slopes are created during excavation, steel-plastic weld geogrids can be used to reinforce and stabilize the slopes. They provide additional strength to the soil, ensuring the safety of mining operations and preventing slope failures.

Environmental Restoration Projects: Steel-plastic weld geogrids are utilized in environmental restoration projects, such as land reclamation or slope rehabilitation. They help to stabilize disturbed slopes, prevent erosion, and promote the establishment of vegetation, contributing to the restoration of natural habitats.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!