Geomembrane Waterproofing 1mm HDPE Liner

HDPE (high-density polyethylene) waterproof film is a material widely used in civil engineering and environmental protection fields, with a thickness of 1mm and excellent waterproof performance. This waterproof film is made of high-density polyethylene material, which has good chemical resistance and UV resistance, and can effectively resist the erosion of various environmental factors. HDPE waterproof membrane has high strength and can withstand significant tensile and compressive forces, ensuring its integrity under different construction conditions. The installation process is relatively simple, usually using hot welding or mechanical fixation to ensure the sealing of the joints. In addition, HDPE waterproof film has a long service life and is suitable for reservoirs, dams, landfills, aquaculture, and other occasions that require waterproof protection. This material not only effectively prevents water infiltration, but also reduces soil pollution and provides protection for the ecological environment.

Geomembrane waterproofing using a 1mm HDPE liner is an effective solution for various applications in construction and environmental engineering. High-Density Polyethylene (HDPE) is known for its durability and resistance to chemicals, UV radiation, and physical damage, making it an ideal choice for lining ponds, landfills, and containment structures. The 1mm thickness provides a robust barrier against water infiltration while maintaining flexibility, which allows it to adapt to ground movements and irregularities. Installation is typically straightforward, involving welding or mechanical fastening, ensuring a secure fit that minimizes the risk of leaks. This type of geomembrane not only protects the environment by preventing contamination of groundwater but also enhances the longevity of the structures it lines. Its lightweight nature and ease of handling contribute to reduced installation costs and time, making it a popular choice among engineers and contractors. Overall, a 1mm HDPE liner represents a reliable and efficient solution for effective waterproofing across a range of industrial and commercial projects.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Advantages of Geomembrane Waterproofing 1mm HDPE Liner

1. Durability: HDPE is highly resistant to punctures, tears, and environmental stress, ensuring long-term performance.

2. Chemical Resistance: The liner can withstand a wide range of chemicals, making it suitable for various applications, including industrial and agricultural uses.

3. UV Stability: HDPE has excellent resistance to UV radiation, reducing the risk of degradation over time when exposed to sunlight.

4. Flexibility: Despite its strength, a 1mm HDPE liner is flexible, allowing it to conform to irregular surfaces and accommodate ground movement.

5. Ease of Installation: The lightweight nature of HDPE makes it easier to handle and install, which can lead to reduced labor costs and installation time.

6. Environmentally Friendly: It serves as an effective barrier to prevent groundwater contamination, supporting environmental protection efforts.

7. Cost-Effectiveness: The long lifespan and low maintenance requirements of HDPE liners contribute to cost savings in the long run.

8. Versatility: Suitable for a variety of applications, including landfills, reservoirs, and agricultural ponds, making it a versatile choice for waterproofing needs.

9. High Tensile Strength: This feature allows the liner to withstand significant stress without failing, enhancing its reliability.

10. Smooth Surface: The smooth finish of the liner reduces friction, which can be beneficial in applications where water flow is involved.

Application of Geomembrane Waterproofing 1mm HDPE Liner

1. Landfills: Used as a primary barrier to prevent leachate from contaminating groundwater, ensuring environmental protection.

2. Reservoirs and Ponds: Provides a waterproof seal for storage of water in agricultural, recreational, and industrial ponds, preventing water loss.

3. Wastewater Treatment: Employed in ponds and lagoons to contain wastewater and prevent seepage, protecting surrounding soil and water sources.

4. Mining Operations: Utilized in tailings ponds and heap leach pads to manage waste materials and prevent contamination of nearby water bodies.

5. Agricultural Applications: Used in irrigation ponds and aquaculture to maintain water levels and quality, ensuring efficient use of resources.

6. Construction Sites: Acts as a barrier in foundation waterproofing, retaining walls, and other structures to prevent water ingress.

7. Dams and Embankments: Provides a protective layer to minimize water seepage and enhance the stability of earth structures.

8. Containment Structures: Used in secondary containment systems for hazardous materials, ensuring that leaks do not escape into the environment.

9. Green Roofs and Landscaping: Serves as a waterproof layer in green roofing systems to protect underlying structures from moisture damage.

10. Civil Engineering Projects: Applied in various projects where groundwater control is critical, such as tunnels and underground facilities.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

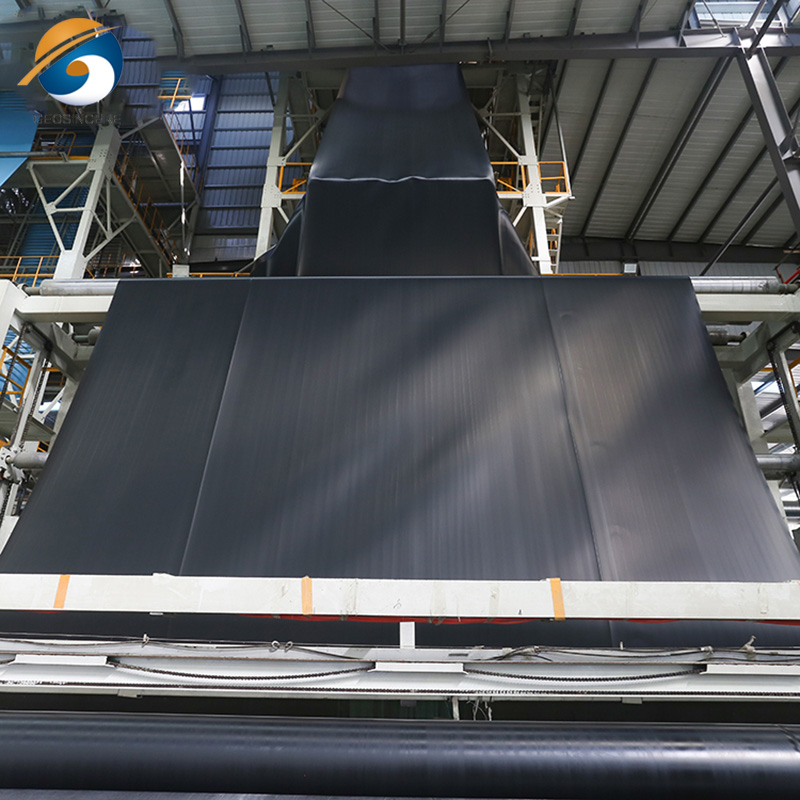

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrana and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembana, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrana research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembrana and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembrana and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembrana and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!