HDPE Uniaxial Plastic Geogrid Price

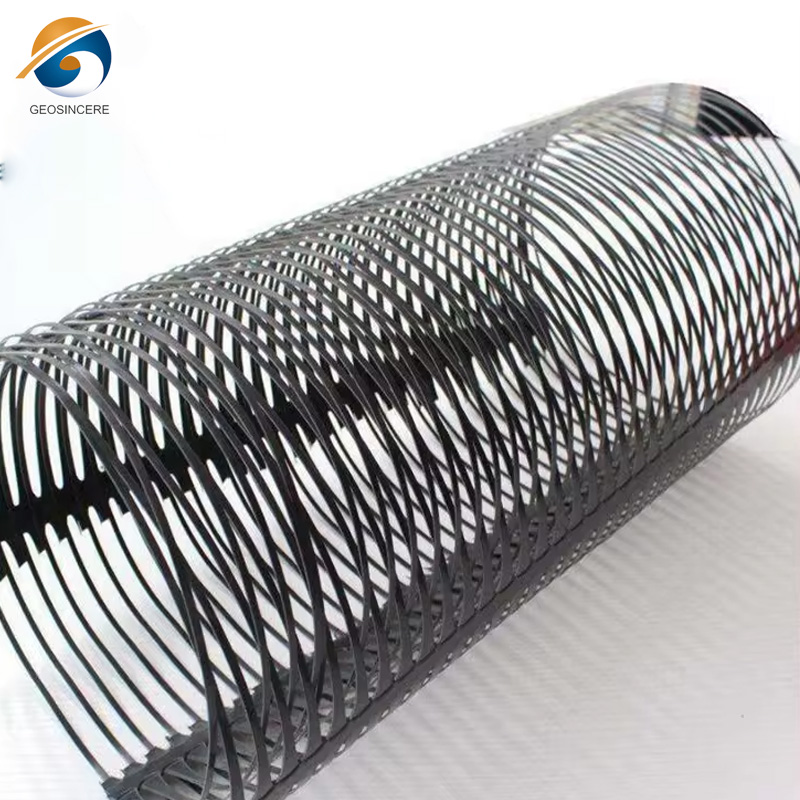

HDPE Uniaxial Plastic Geogrid is a plastic grid made of high-density polyethylene, mainly used in the field of geotechnical engineering. This type of grille has excellent tensile strength and corrosion resistance, and can be widely used in road, railway, riverbank, and other infrastructure construction.

The production process adopts advanced extrusion technology to ensure that the grille has uniform mechanical properties and stable dimensions. Products are usually supplied in the form of rolls, which are easy and fast to install, can greatly improve construction efficiency, and reduce overall project costs.

With excellent quality and performance characteristics, HDPE Uniaxial Plastic Geogrid has become a popular product in the field of geotechnical engineering. Its price is reasonable and matches the product quality and application prospects. The wide range of applications and stable market demand make this product one of the preferred materials in geotechnical engineering construction.

HDPE Uniaxial Plastic Geogrid is a new type of geogrid product widely used in soil reinforcement, roadbed reinforcement, slope protection and other fields. It is made of high-density polyethylene (HDPE) material, which has excellent tensile strength and chemical resistance. This type of grille undergoes unidirectional stretching during the manufacturing process, forming a high-strength and high rigidity unidirectional mesh structure. Compared with traditional 3D geogrids, HDPE Uniaxial Plastic Geogrid is more lightweight, easy to lay, and can effectively improve the shear strength and tensile performance of soil. In addition, the grid adopts a grid like design, which can generate good friction and interlocking with the soil material, enhance the bonding force of the soil grid interface, and further improve the overall anti-skid effect. HDPE Uniaxial Plastic Geogrid is widely used in the reinforcement and strengthening of infrastructure projects such as highways, railways, airports, and water conservancy, and is a cost-effective new type of geotechnical material.

Parameter

Properties | BGUG 25 | BGUG 35 | BGUG 50 | BGUG 80 | BGUG 110 | BGUG 120 | BGUG 150 | |

Width(mm) | 1100 | |||||||

Length /roll (m) | 50 | |||||||

Yield strength ≥kN/M | HDPE | 25 | 35 | 50 | 80 | 110 | 120 | 150 |

PP | 25 | 35 | 50 | 80 | 110 | 120 | 150 | |

Elongation | HDPE (%) | 11-16 | ||||||

PP≤ (%) | 10 | |||||||

Strength at 2% elongation ≥kN/M | HDPE | 6 | 9 | 10 | 23 | 30 | 35 | 46 |

PP | 7 | 10 | 12 | 26 | 32 | 38 | 48 | |

Strength at 5% elongation ≥kN/M | HDPE | 12 | 18 | 25 | 44 | 60 | 70 | 87 |

PP | 14 | 20 | 28 | 48 | 64 | 75 | 93 | |

HDPE Uniaxial Plastic Geogrid Features

1. Excellent tensile strength: Using a special production process, HDPE Uniaxial Plastic Geogrid has excellent tensile strength and can effectively withstand various stresses and tensile forces in geotechnical engineering.

2. Corrosion resistance: The high-density polyethylene material endows this product with excellent corrosion resistance, enabling long-term stable use in harsh environmental conditions.

3. Dimensional stability: Advanced production technology ensures the dimensional accuracy and stability of the grille, ensuring that no deformation occurs during installation and use.

4. Convenient construction: The HDPE Uniaxial Plastic Geogrid supplied in roll form is fast and easy to install, greatly improving the efficiency of engineering construction.

5. Affordable: The reasonable price matched with excellent performance characteristics makes this product an economical and practical choice in the field of geotechnical engineering.

Overall, HDPE Uniaxial Plastic Geogrid has become one of the key materials widely favored in geotechnical engineering construction due to its excellent performance characteristics and economic practicality.

Applications of HDPE Uniaxial Plastic Geogrid

1. Highway construction:

-Used for roadbed reinforcement, improving the bearing capacity and stability of the roadbed

-Applied to reinforce weak roadbeds and prevent deformation of roadbeds

-Used for reinforcing and anti slip slopes of high fill roadbeds

2. Railway engineering:

-As a reinforcement material for track subgrade, it improves the bearing capacity of the subgrade

-Used for reinforcing and stabilizing weak roadbeds

-Anti slip slope applied to high fill railway subgrade

3. Embankment and riverbank protection:

-As a reinforcement material for dams, it improves the shear and tensile strength of dams

-Applied to riverbank slope protection to prevent soil erosion and slope instability

4. Landfill site:

-Used for reinforcing the cover layer of landfills to improve their anti slip ability

-Applied to landfill slope reinforcement to prevent landslides

5. Site filling:

-As a reinforcement material for filling soil, it improves the stability of the fill soil

-Applied to the reinforcement and improvement of weak foundations

In summary, HDPE Uniaxial Plastic Geogrid is widely popular and applied in various geotechnical engineering fields due to its excellent mechanical properties and corrosion resistance. Its reliable quality and economic practicality make it one of the preferred materials in infrastructure construction.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!