Impermeable Composite Geomembrane Plastic Dam Linings

Impermeable composite geomembrane plastic dam linings, also known as impermeable geomembranes or plastic liners, are specialized materials used to line and seal dams and reservoirs. They provide a waterproof barrier that prevents water seepage, ensuring effective water containment.They ensure the integrity and efficiency of water storage by providing a durable and impermeable barrier.

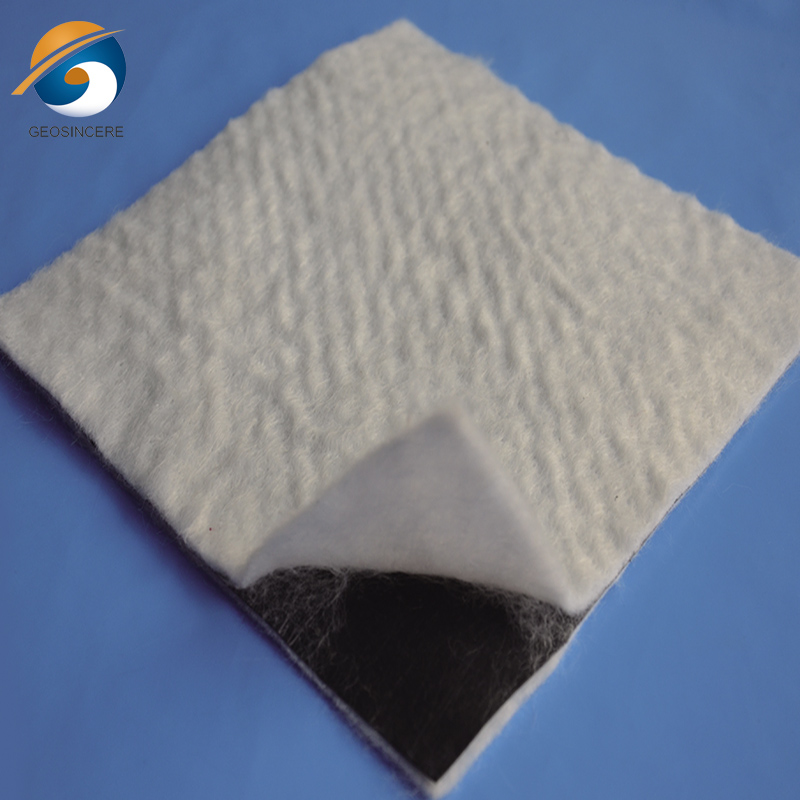

The primary function of impermeable geomembranes is to create a watertight barrier within the dam or reservoir structure. They prevent water from seeping through the dam walls or base, reducing the risk of leakage and ensuring efficient water storage.Impermeable composite geomembranes are often made with multiple layers for enhanced performance. These layers can include a core layer of impermeable plastic material sandwiched between two protective layers. The protective layers provide resistance against punctures, UV degradation, and other potential damage.

Impermeable composite geomembrane plastic dam linings are specialized liner systems designed for water containment in dam construction and rehabilitation projects.The primary purpose of impermeable composite geomembrane plastic dam linings is to provide a barrier that prevents water seepage through the dam structure. They act as impermeable barriers to ensure effective water containment and prevent loss or leakage of water.

These liners are typically made of high-density polyethylene (HDPE) or other plastic materials known for their impermeability, durability, and resistance to UV radiation, chemicals, and punctures. The liners may consist of multiple layers or a composite structure, combining different materials for enhanced performance.Impermeable composite geomembrane plastic dam linings often comprise multiple layers, each serving a specific function. For example, a typical composite structure may include a smooth HDPE layer for impermeability, a geosynthetic clay liner (GCL) for added hydraulic conductivity reduction, and a protective non-woven geotextile layer for mechanical protection.

Impermeable composite geomembrane plastic dam linings play a crucial role in preventing water leakage through the dam structure. They help maintain the desired water levels in the reservoir, prevent seepage into the surrounding soil or groundwater, and minimize the risk of dam failure.These liners are designed to withstand the challenging environmental conditions associated with dam construction. They are engineered to have excellent durability, resistance to chemical degradation, and long-term performance to ensure the integrity of the dam structure over its lifespan.

The impermeable liners contribute to environmental protection by preventing water loss, protecting downstream ecosystems, and avoiding potential soil erosion or contamination associated with uncontrolled water seepage.Impermeable composite geomembrane plastic dam linings provide a reliable solution for water containment in dam construction and rehabilitation projects. They ensure the integrity and stability of dams, reduce water loss, and contribute to the sustainable management of water resources.

Parameter

Test ltem | Test Properties | Unit | BCM4 | BCM5 | BCM5 | BCM7 | BCM8 |

Weight | g/㎡ | 400 | 500 | 600 | 700 | 800 | |

Film Thickness | Mm | 0.25-0.35 | 0.30-0.50 | ||||

Mechanical Properties | Break Strength | kN/m | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 |

Break Elongation | % | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 | |

CBR Burst Strength | KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | |

Tear Resistance | KN | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | |

Peel Strength | N/cm | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | |

Hydrostatic Pressure | Film Thickness | Mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 |

One cloth one film | Mpa | 0.4 | 0.5. | 0.6 | 0.8 | 1.0 | |

Two cloth one film | Mpa | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | |

Impermeable Composite Geomembrane Plastic Dam Linings Features

•High friction coefficient, excellent wear resistance

•Stable low temperature embrittlement resistance.

•Excellent impermeable, leak and moisture proof

•High tensile strength and tearing strength

•Excellent chemical resistance

•Anti-aging and anti-corrosion.

•High strength, anti puncture

•Easy to deploy efficiently

•Excellent UV resistance

•Cost saving

Applications of Impermeable Composite Geomembrane Plastic Dam Linings

Impermeable composite geomembrane plastic dam linings find a range of applications in various dam construction and rehabilitation projects. Here are some common applications:

New Dam Construction: These liners are used in the construction of new dams to provide an impermeable barrier that prevents water seepage through the dam structure. They are installed on the upstream face of the dam to ensure effective water containment and prevent loss or leakage of water.

Dam Rehabilitation: Impermeable composite geomembrane plastic dam linings are also employed in the rehabilitation and repair of existing dams. They can be used to repair leaks or reinforce the existing lining system, enhancing the overall impermeability of the dam and extending its service life.

Reservoirs and Storage Ponds: These liners are utilized in the construction of reservoirs and storage ponds to create an impermeable barrier that prevents water seepage. They help maintain the desired water levels, prevent water loss, and ensure efficient water storage for various purposes, such as irrigation, drinking water supply, or industrial use.

Tailings and Waste Containment: Impermeable liners are employed in the construction of containment areas for tailings or waste materials. They create an impermeable barrier that prevents the seepage of potentially harmful substances into the surrounding environment, protecting soil and groundwater from contamination.

Irrigation Canals and Channels: Impermeable composite geomembrane plastic liners are used in irrigation systems to line canals, channels, and other water conveyance structures. They prevent water seepage, ensuring efficient water delivery to agricultural fields and reducing the loss of water resources.

Pond and Lagoon Liners: These liners are utilized in the construction of ponds and lagoons for various purposes, such as wastewater treatment, aquaculture, or stormwater management. They provide an impermeable barrier that prevents the seepage of water into the surrounding soil, ensuring effective containment and management of liquids.

Landfill Liners: Impermeable liners are employed in the construction of landfill cells or containment areas. They prevent the seepage of leachate, which is the liquid generated from waste decomposition, into the surrounding environment. This helps protect groundwater quality and minimize the risk of environmental contamination.

Mining and Industrial Applications: Impermeable composite geomembrane plastic linings are used in mining operations and industrial facilities for containment of process liquids, tailings, or other waste materials. They provide an impermeable barrier that helps prevent environmental contamination and ensures compliance with regulatory requirements.

Impermeable composite geomembrane plastic dam linings are versatile and offer effective water containment solutions in a wide range of applications. They contribute to the efficient management of water resources, environmental protection, and the sustainable operation of infrastructure projects.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

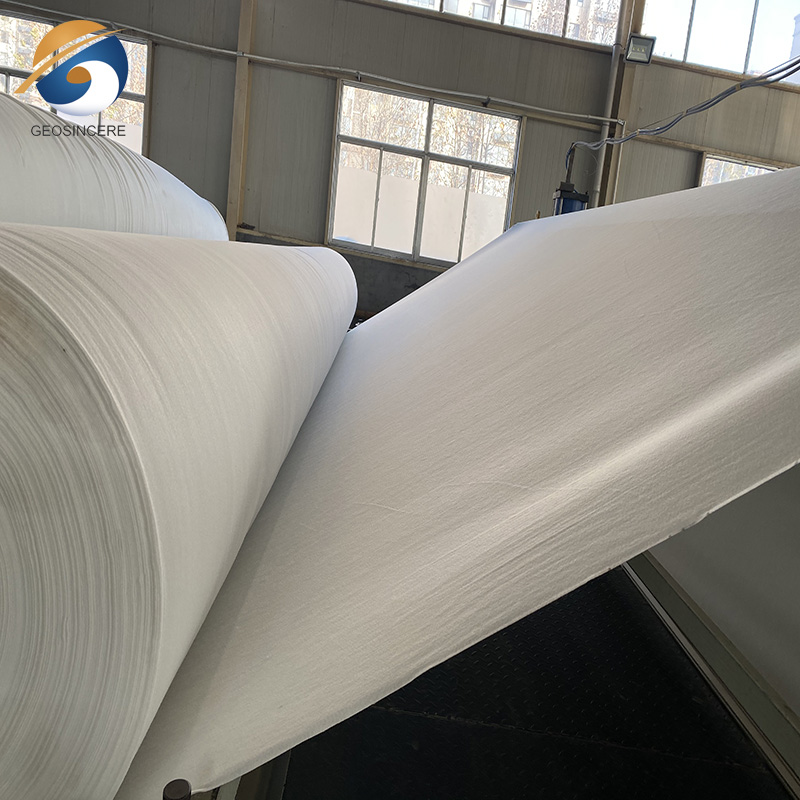

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!