Geosynthetic Clay Liners Landfill Liner Material

Geosynthetic Clay Liners (GCLs) are indeed innovative and highly effective materials used as landfill liners. They are designed to provide superior containment and environmental protection in waste disposal sites. GCLs combine the geotechnical properties of natural clays with the enhanced performance of geosynthetics, resulting in a versatile and reliable barrier system.

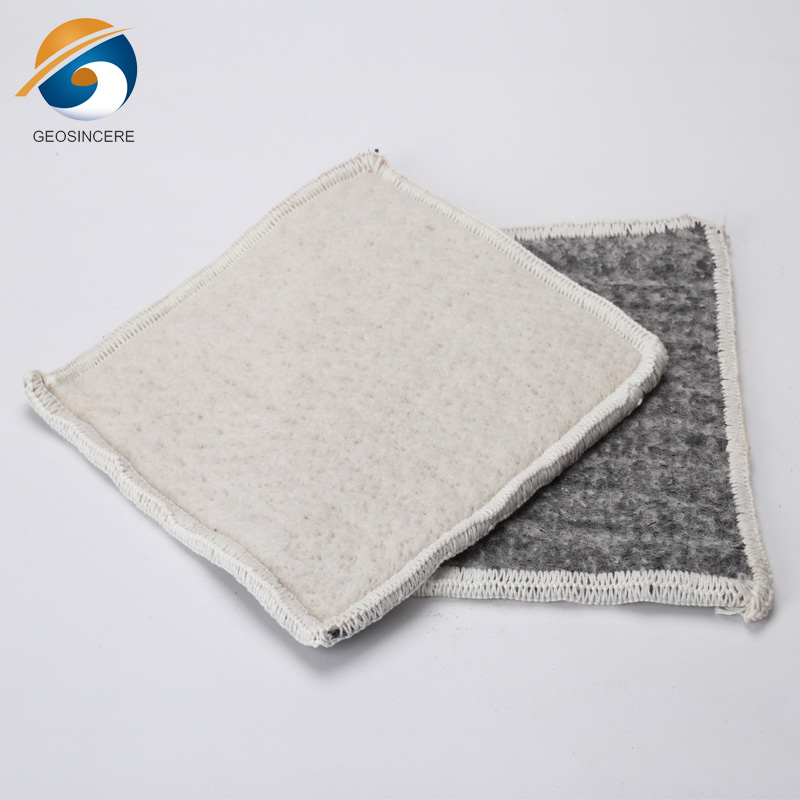

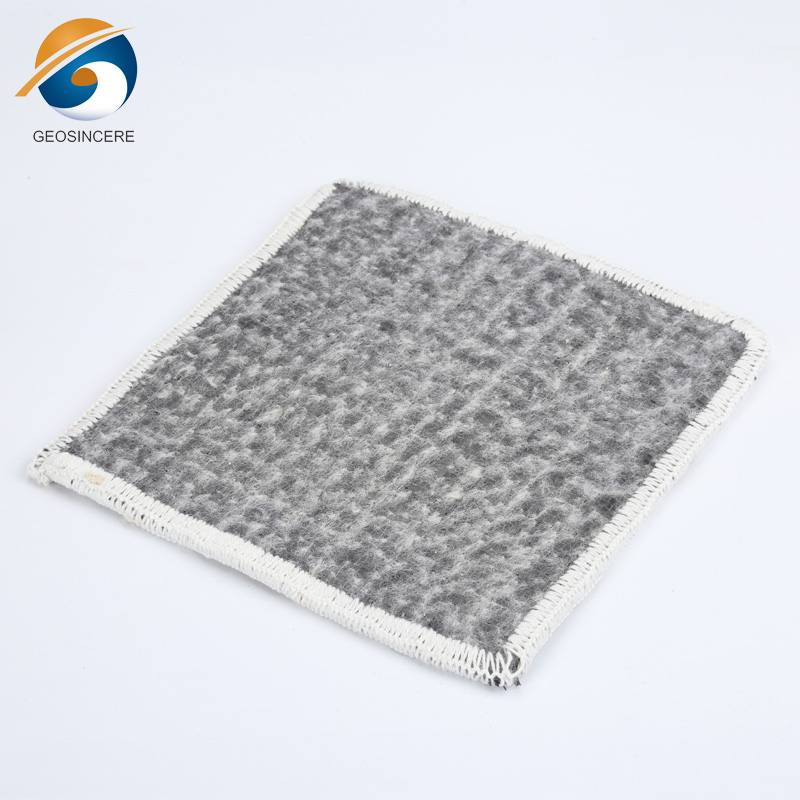

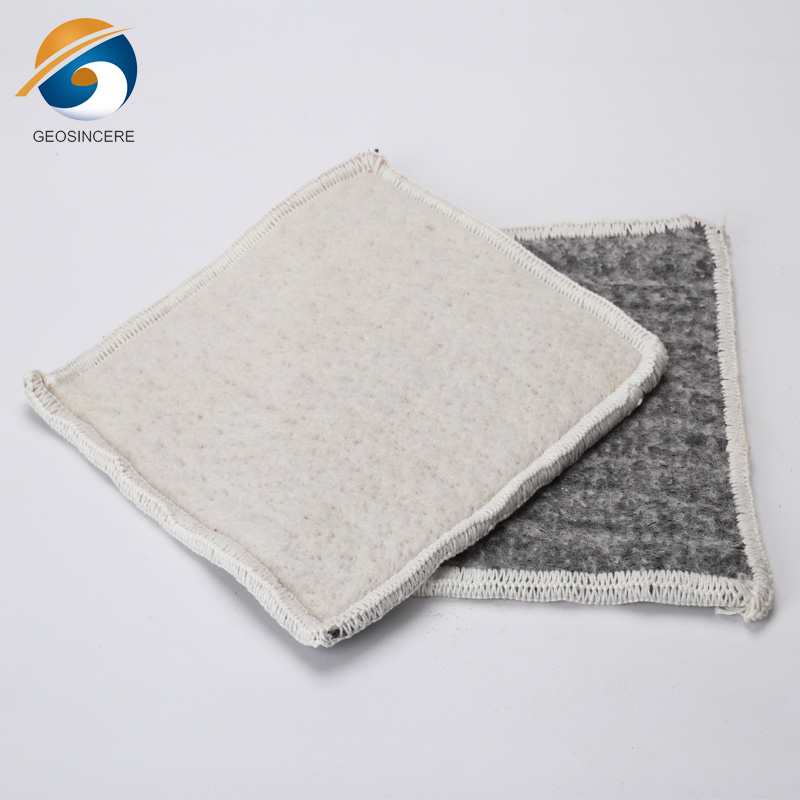

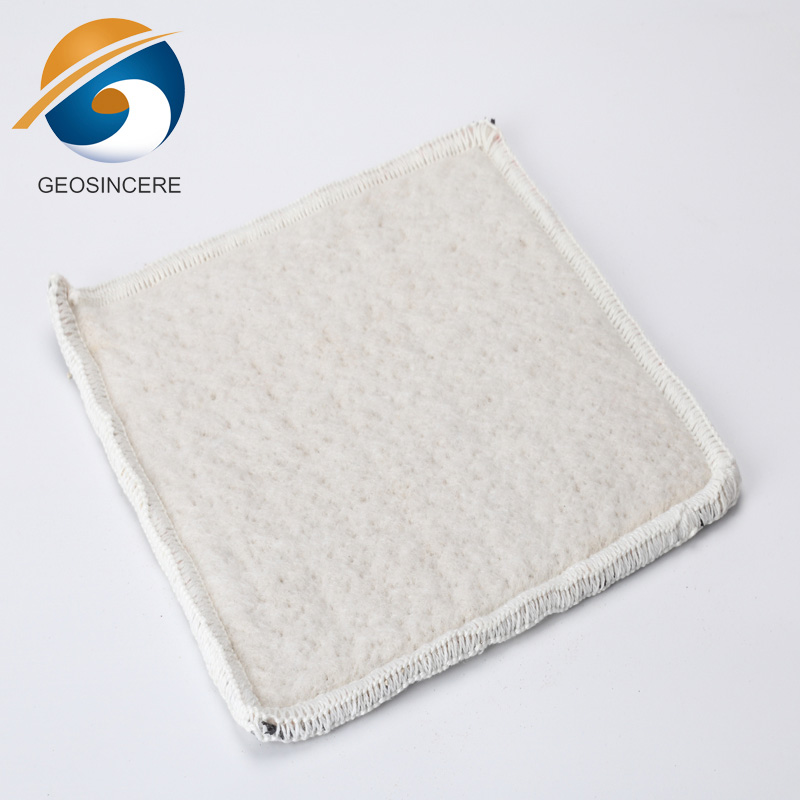

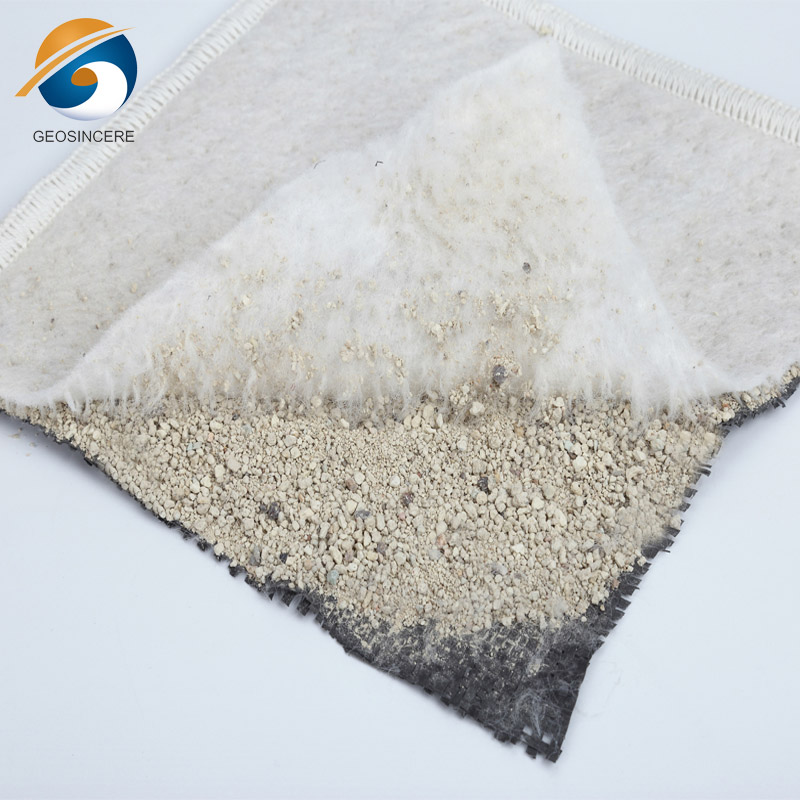

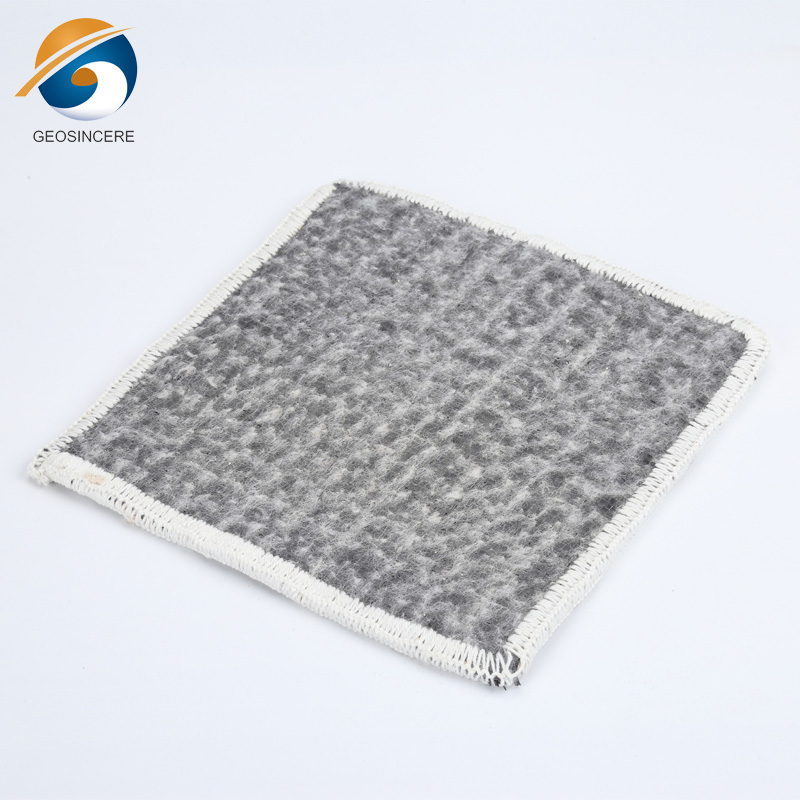

GCLs consist of a layer of bentonite clay sandwiched between two geotextile layers. Bentonite clay is a naturally occurring material known for its low permeability and swelling characteristics when hydrated. The geotextile layers, typically made of woven or non-woven synthetic materials, provide reinforcement and mechanical stability to the liner system.

Geosynthetic Clay Liners (GCLs) are innovative and highly effective materials used in landfill liner systems. They are designed to combine the geotechnical properties of clay with the enhanced performance of geosynthetics, resulting in a liner material that offers several advantages for waste containment.

GCLs provide excellent containment properties, serving as a barrier that prevents the migration of liquids, gases, and pollutants from the landfill site into the surrounding environment. The high swelling capacity of the clay component helps to create a self-sealing barrier, reducing the risk of leakage.GCLs exhibit good resistance to a wide range of chemicals found in landfill environments, including acids, alkalis, and organic compounds. This chemical resistance helps to maintain the integrity of the liner and prevents degradation over time.

GCLs have gained popularity in landfill engineering due to their combination of geotechnical and geosynthetic properties. They help to mitigate environmental risks associated with waste disposal, protect groundwater resources, and promote sustainable waste management practices.

Parameter

Properties | Unit | Test Method | Frequency | Value |

GCL Property | ||||

Bentonite mass per unit area | g/m2 | ASTM D 5993 | 4000m2 | 3600g/m2 MARV |

Tensile Strength | kN/m | ASTM D 6768 | 4000m2 | 6kN/m MARV |

Peel Strength | N | ASTM D 4632 | 4000m2 | 65N MARV |

Hydraulic conductivity | cm/s | ASTM D 5887 | periodically | 5x10-2cm/sec MARV |

Shear Strength | kPa | ASTM D 6243 | periodically | 24 kPa Typical |

Geotextitle Property | ||||

g/m2 | ASTM D 5261 | 20,000m2 | 200 g/m2 MARV | |

Cap woven geotextile | g/m2 | ASTM D 5261 | 20,000m2 | 200 g/m2 MARV |

Bentonite property | ||||

Swell index | Kg | ASTM D 5890 | 50,000Kg | 24mI/2g MARV |

Moisture content | % | ASTM D 4643 | 50,000Kg | 12% max |

Fluid loss | ml | ASTM D 5891 | 50,000Kg | 18ml max |

Roll Dimensions | ||||

Width*Length | m | Typical | each roll | 5.8×30 |

Area Per Roll | m2 | Typical | each roll | 174 |

Packaged Weight | kg | Typical | each roll | 935 |

20GP loading | roll | Typical | each roll | 20 |

20GP loading Note: 1. Variation allowed 2%. 2.GCL Unit weight can be 5000g/m2.5500g/m2 .6000g/m2 3.Nonwoven Geotextile can be PP or PET material. | ||||

Geosynthetic Clay Liners Landfill Liner Material Features

1. Clay Core: The GCL consists of a layer of natural or processed sodium bentonite clay, which acts as the primary hydraulic barrier. Bentonite clay has exceptional swell and self-sealing properties, providing an impermeable layer to prevent the migration of liquids and gases.

2. Geotextile Layers: The clay core is encapsulated between two geotextile layers, typically made of woven or non-woven geotextile fabrics. These layers act as reinforcement, providing strength, puncture resistance, and stability to the GCL.

3. Composite Structure: The combination of clay and geotextile layers creates a composite structure that enhances the overall performance of the liner.

4. High Hydraulic Conductivity: GCLs have low permeability, minimizing the migration of leachate from the landfill and protecting the surrounding soil and groundwater from contamination.

5. Chemical Resistance: GCLs exhibit excellent resistance to a wide range of chemicals commonly found in landfill environments, including acids, bases, and organic solvents.

6. Environmental Benefits: By effectively containing waste materials and preventing their interaction with the surrounding environment, GCLs contribute to the protection of soil, water, and air quality. They help mitigate the potential risks associated with landfill operations.

Applications of Geosynthetic Clay Liners Landfill Liner Material

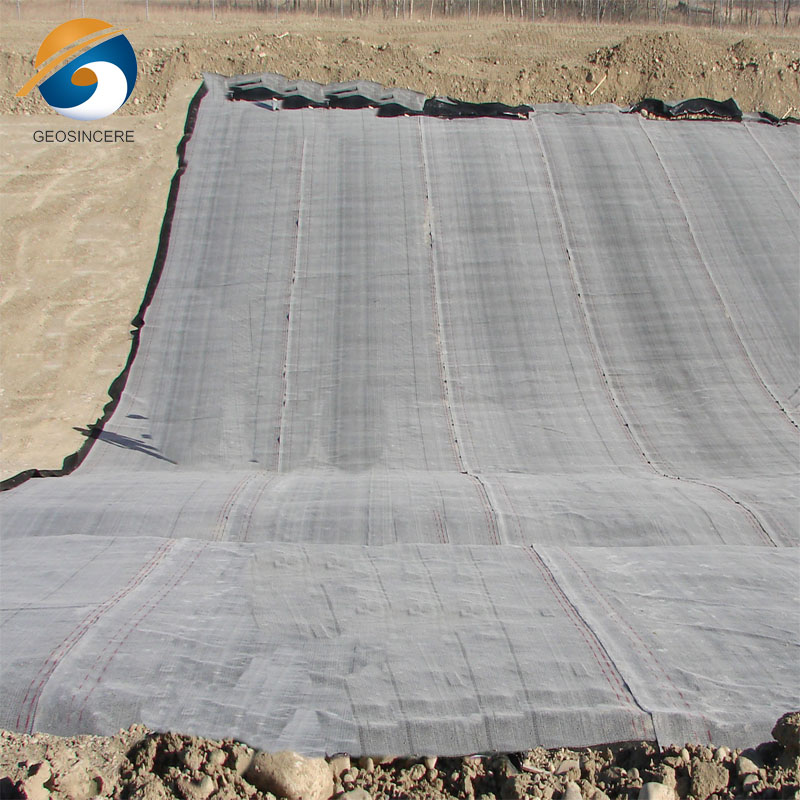

Geosynthetic Clay Liners are widely used in landfill construction and containment systems. They are suitable for various applications, including:

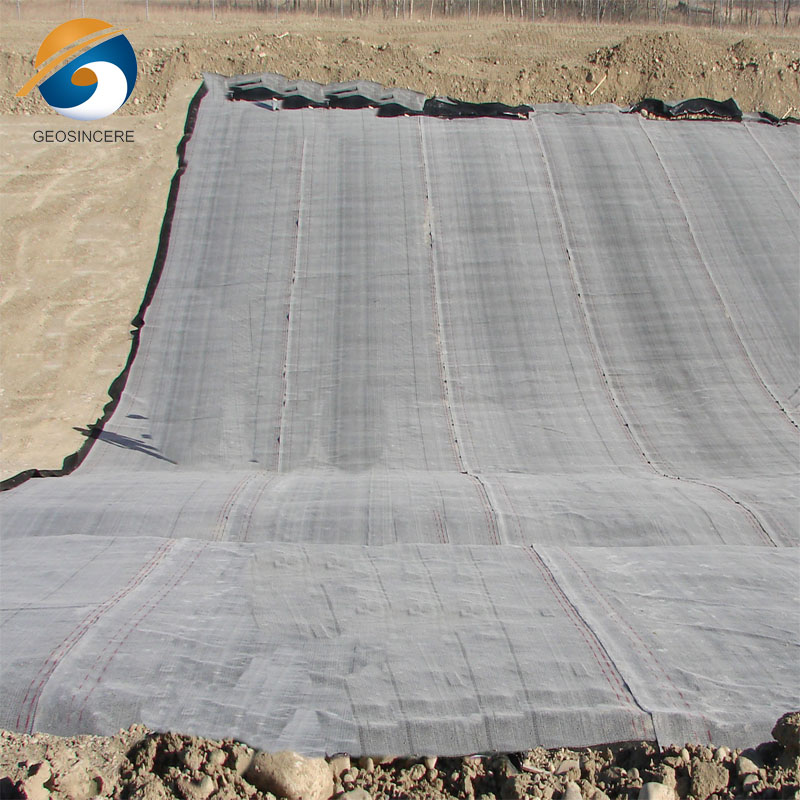

1. Landfill Base Liners: GCLs serve as primary barrier systems, preventing the migration of leachate into the underlying soil and groundwater.

2. Landfill Caps: GCLs are used in the closure and capping of landfill sites, providing a final barrier to prevent the infiltration of water and the release of gases.

3. Secondary Containment: GCLs are employed in secondary containment systems for hazardous waste storage facilities, preventing the escape of contaminants into the environment.

4. Pond and Reservoir Liners: GCLs can be utilized in the construction of liners for ponds, reservoirs, and wastewater treatment facilities, ensuring efficient containment and preventing seepage.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!