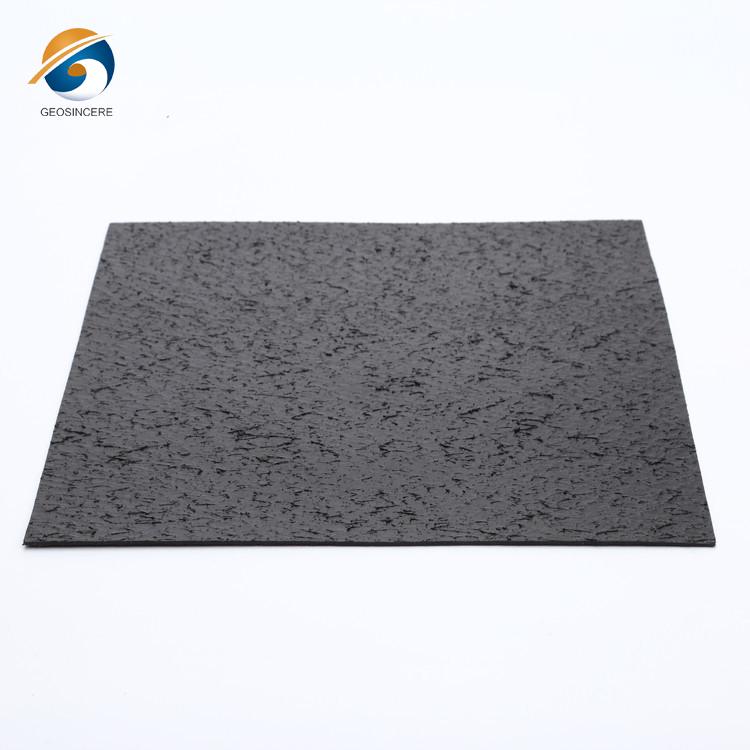

Sealable Textured HDPE Geomembrane Pond Liner

GEOSINCERE is a leading manufacturer and supplier of textured HDPE geomembranes. These geomembranes are designed and fabricated with either a single-sided or double-sided textured surface. The rough texture of the geomembrane greatly improves the friction coefficient, making it suitable for steep slopes and vertical engineering designs. This maximizes the effective volume of the geomembrane. The textured geomembranes also have smooth edges, allowing for high-quality thermal fusion welding between adjacent sheets.

GEOSINCERE textured HDPE geomembranes are made using imported raw materials and advanced manufacturing equipment. They are produced using professional production technology and are packed in double woven geotextile and strength belts. These geomembranes have superior shear strength and exhibit the highest multi-axial performance. They have a high shear strength, large friction angles, outstanding elongation, and the highest interface surface friction coefficient.

These textured HDPE geomembranes find wide application in various projects that require increased friction between two layers and are suitable for high steeper slopes. They are commonly used in applications such as landfills, mining, retaining backfills, and waste containment.

GEOSINCERE textured HDPE geomembranes are manufactured using imported raw materials and advanced manufacturing equipment. They have obtained several certifications, including ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates. They have also undergone testing by reputable organizations such as SGS and Intertek, further validating their quality and performance.

Parameter

Test Properties | Unit | Standard | Test frequency | BM10 | BM15 | BM20 | BM25 |

Thickness | mm | D5994 | per roll | 1.00 | 1.50 | 2.00 | 2.50 |

Asperity Height | mm | D7446 | Every 2nd roll (2) | 0.25 | |||

Density | g/cc | D1505/0792 | 90.000kg | 0.94 | |||

Tensile Properties | |||||||

Yield Strength | Kn/m | D6693 Type Iv | 9.000 kg | 15 | 22 | 29 | 37 |

Break Strength | Kn/m | 10 | 16 | 21 | 26 | ||

Yield Elongation | % | 12 | 12 | 12 | 12 | ||

Break Elongation | % | 100 | 100 | 100 | 100 | ||

Tear Resistance | n | D1004 | 20.000kg | 125 | 187 | 249 | 311 |

Puncture Resistance | n | D4883 | 20,000kg | 267 | 400 | 534 | 667 |

Stress Crack Resistance | hr | D5397(App) | per GRlGM-10 | 300 hr | |||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||

0xidative Induction Time | |||||||

Standard OlT | Min | D3895 | 90.000kg | 100 min | |||

High pressure OlT | D5885 | 90.000kg | 400 min | ||||

Oven Aging at 85°C retained after 90 days | % | D5721 | per each formulation | 55% | |||

Standard 0lT | D3895 | 80% | |||||

High pressure OlT | D5885 | 80% | |||||

UV Resistance | |||||||

High Pressure OlT -% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||

Roll Width | m | 7 | 7 | 7 | 7 | ||

Roll Length | m | 210 | 140 | 105 | 70 | ||

Size stability | % | 2% | |||||

Textured Geomembrane Liner Features

1. Can be textured on one or both sides for your demands.

2.Increased frictional coefficient for steep slopes.

3.Outstanding ultraviolet and chemical resistance.

4.Outstanding UV Environmental stress crack resistance.

5.High tensile strength and low elongation.

6.Excellent friction coefficient and tensile strength with Geotextile reinforcement performance.

7.Excellent water impermeability, corrosion and aging resistance.

8.Advanced stabilization.

9.Light weight, easy construction and good overall continuity.

10.Imported Virgin HDPE Raw Material.

11.Single- or double-sided textured surface.

12.Meets or exceeds all aspects of GRI GM13.

13.Cost effective, Factory price.

14.ODM/OEM are available.

Applications of Textured Geomembrane Liner

Textured HDPE geomembrane is specially designed and fabricated for landfills and mining applications due to its advanced stabilization, excellent interface friction coefficient and inherent flexibility. As flexibility as our other GEOSINCERE geomembrane, textured HDPE geomembranes have been widely in backfilled liner, retaining backfill on steep side, heap leach pads, landfill and pad base liner, water conservancy applications such as dam, reservoirs, sewage pools, swimming pools, buildings, underground buildings, garbage dumps and mining projects.

1.Oil and Gas: Chemical plant, refinery, oil storage tank etc.

2.Solid or liguid waste treatment: Landfill,waste water plant,industrial or hospital wastetreatment site anti-seepage

3.Water conservancy Project: River Embankment, lake Dam, tailing dam, sewage dam andreservoir,channel,Vertical wall, slope protection seepage contro

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner.