Nonwoven Needle Punched Geotextile Underlayment Fabric

Nonwoven needle-punched geotextile underlayment fabric is a specialized material used in civil engineering and construction applications. It is designed to provide reinforcement, separation, filtration, and drainage functions in various geotechnical projects.

Nonwoven geotextile underlayment fabric is often used to stabilize soils in road construction, parking lots, and other infrastructure projects.The fabric improves the overall stability and load-bearing capacity of the soil, reducing settlement and improving the longevity of the structure.Additionally, the fabric acts as a filtration layer, allowing water to pass through while preventing the migration of fine particles. This helps to prevent clogging and maintain the long-term functionality of drainage systems.

Nonwoven needle-punched Geotextile underlayment fabric is a specialized material used in civil engineering and construction projects. It is designed to provide a variety of functions when placed between different layers of soil, aggregates, or other geotechnical materials. The primary function of geotextile underlayment fabric is to separate different layers of soil or aggregate materials. It prevents the mixing or intermingling of dissimilar soils or aggregates, such as subsoil and base course materials. This separation helps maintain the integrity and performance of each layer, preventing contamination and maintaining proper drainage.

Geotextile underlayment fabric acts as a filtration layer, allowing water to pass through while preventing the migration of fine particles. It helps retain soil particles within the intended layer, preventing clogging of drainage systems and maintaining the stability and permeability of the construction materials.Nonwoven needle-punched geotextile underlayment fabric can facilitate drainage by allowing water to flow freely through the material. It helps prevent the buildup of excess water pressure and reduces the risk of waterlogging, which can compromise the stability of the construction.Geotextile underlayment fabric can be used in erosion control applications. It helps stabilize soil and prevents soil erosion by providing a protective barrier against hydraulic forces, such as water flow or wave action. The fabric helps retain soil particles in place, reducing the risk of erosion and maintaining the stability of slopes, embankments, and other soil surfaces.

Geotextile underlayment fabric provides a protective layer between different materials or surfaces. For example, it can be used to protect geomembranes or other impermeable liners from puncture or abrasion by providing a cushioning effect. It can also protect drainage pipes or other buried utilities from damage caused by soil movement or external loads. In some applications, geotextile underlayment fabric can provide soil reinforcement. By distributing tensile forces and enhancing soil stability, it can improve the load-bearing capacity of weak or unstable soils. This reinforcement can be beneficial in applications such as road construction, retaining walls, and reinforced slopes.Geotextile underlayment fabric can serve as a weed barrier in landscaping and gardening applications. It can be placed beneath mulch or gravel to suppress weed growth and reduce the need for chemical herbicides. The fabric allows water and nutrients to penetrate while blocking sunlight, inhibiting weed germination and growth.

Parameter

Item | Test Method | Unit | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

Index Properties | ||||||||||||

Ultimate Tensile Strength. MD | ASTM D4595 | KN/m | 1 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

Ultimate Tensile Strength, TD | ASTM D4595 | KN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Grab Tensile Strength. MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

Grab Tensile Strength, TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Trapezoid Tear Strength. MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

Trapezoid Tear Strength, TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

Apparent Opening Size 090 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Water Flow Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

Weight | ASTM D5261 | G/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

Roll width | / | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

Roll Length | / | m | 300 | 200 | 150 | 100 | 100 | 100 | 80 | 80 | 50 | 50 |

Nonwoven Needle Punched Geotextile Underlayment Fabric Features

Nonwoven Needle Punched Geotextile Underlayment Fabric possesses several notable features that make it an excellent choice for various applications. These features include:

High Tensile Strength

Puncture Resistance and Durability

Anti-corrosion Properties

Anti-aging Characteristics

Excellent Permeability and Filtration

Acid and Alkali Resistance

Increased Performance Life of the Road

Withstands Tough Construction Loading

Easy Installation

Applications of Nonwoven Needle Punched Geotextile Underlayment Fabric

Nonwoven needle-punched geotextile underlayment fabric has a wide range of applications in civil engineering and construction projects. Here are some common applications:

Road Construction: Nonwoven geotextile underlayment fabric is commonly used in road construction projects. It is placed between the subgrade (existing soil) and the base course (aggregate layer) to provide separation and filtration. It prevents the mixing of soil and aggregate, enhances the stability of the roadbed, and helps to control moisture by allowing water to drain while preventing the migration of fine particles.

Landfills and Waste Containment: Geotextile underlayment fabric is used in landfill liner systems and waste containment facilities. It acts as a separation and filtration layer, preventing the mixing of different soil layers and facilitating proper drainage. It also provides protection for the geomembrane liner by acting as a cushioning layer and reducing the risk of punctures or damage during installation and operation.

Retaining Walls and Slope Stabilization: Nonwoven geotextile underlayment fabric is often employed in retaining wall and slope stabilization applications. It is placed between the backfill soil and the facing materials or geogrids to enhance the stability of the structure. The fabric prevents soil erosion, promotes proper drainage, and improves the load-bearing capacity of the soil, reducing the risk of slope failure.

Landscaping and Erosion Control: Geotextile underlayment fabric is used in landscaping projects for erosion control and soil stabilization. It can be placed beneath mulch or gravel to prevent soil erosion, control weed growth, and maintain the stability of sloped areas. The fabric allows water to drain while retaining soil particles, providing a protective barrier against hydraulic forces.

Subsurface Drainage: Nonwoven geotextile underlayment fabric is utilized in subsurface drainage systems. It is placed around perforated pipes or drains to prevent the migration of fine particles into the drainage system. The fabric acts as a filter, allowing water to flow through while retaining soil particles, preventing clogging and maintaining the long-term performance of the drainage system.

Railways and Airport Runways: Geotextile underlayment fabric is used in railway and airport runway construction. It provides separation and filtration between the subgrade and the ballast or base course materials. The fabric prevents the mixing of soil and aggregates, improves the load distribution, and enhances the stability and performance of the railway or runway.

Foundation and Basement Waterproofing: Nonwoven geotextile underlayment fabric can be used in foundation and basement waterproofing systems. It is placed against the exterior wall to act as a separation layer between the backfill soil and the waterproofing membrane. The fabric helps to protect the waterproofing system from damage during backfilling, provides drainage paths for water, and prevents the intrusion of fine particles.

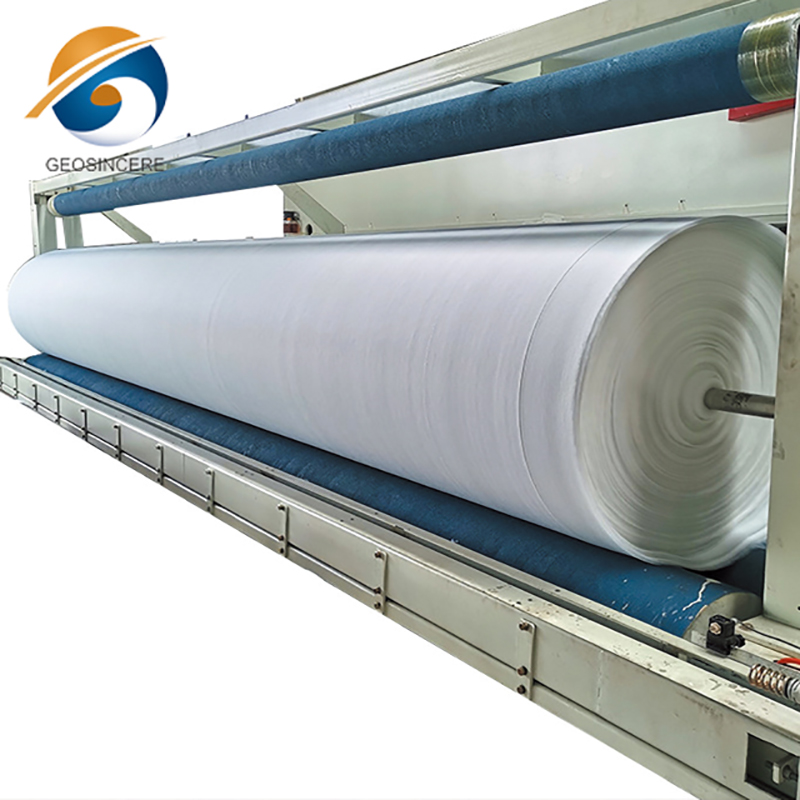

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!