Non Woven Geotextile Drainage Fabric for Driveway

Non-woven geotextile drainage fabric is an essential material for driveway construction, particularly in areas where water management is crucial. This fabric is crafted from synthetic fibers, such as polypropylene or polyester, which are bonded together through a process that enhances their strength and durability. The non-woven structure allows for excellent water permeability, enabling it to efficiently filter and drain excess moisture while preventing the migration of soil particles. When installed beneath a driveway surface, this geotextile fabric acts as a protective barrier, stabilizing the subgrade by distributing the weight of vehicles and reducing the risk of ruts or depressions over time. Its high tensile strength ensures that it can withstand the heavy loads typically associated with driveways, while its resistance to environmental factors, such as UV rays and chemical exposure, contributes to its longevity. Additionally, the use of non-woven geotextile drainage fabric promotes effective drainage systems, minimizing water pooling and enhancing the overall performance of the driveway.

Non-woven geotextile drainage fabric is a crucial component in the construction and maintenance of driveways, particularly in areas prone to water accumulation and soil instability. This type of fabric is engineered from synthetic fibers, typically polypropylene or polyester, which are bonded together through a thermal or chemical process, creating a mat-like structure that is both strong and flexible. The unique composition of non-woven geotextiles allows for high permeability, enabling water to pass through while effectively filtering out soil particles and sediments. This characteristic is essential for preventing the clogging of drainage systems, thus promoting effective water management.

They act as a protective layer between the soil and the driveway surface, reducing the risk of erosion and maintaining the integrity of the underlying soil structure. The fabric helps distribute the load of vehicles evenly, minimizing the potential for ruts and depressions that can develop over time. Additionally, by allowing water to drain away swiftly, non-woven geotextiles help prevent water pooling, which can lead to surface damage and structural issues.

Parameter

Item | Test Method | Unit | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

Index Properties | ||||||||||||

Ultimate Tensile Strength. MD | ASTM D4595 | KN/m | 1 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

Ultimate Tensile Strength, TD | ASTM D4595 | KN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Grab Tensile Strength. MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

Grab Tensile Strength, TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Trapezoid Tear Strength. MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

Trapezoid Tear Strength, TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

Apparent Opening Size 090 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Water Flow Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

Weight | ASTM D5261 | G/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

Roll width | / | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

Roll Length | / | m | 300 | 200 | 150 | 100 | 100 | 100 | 80 | 80 | 50 | 50 |

Advantages of Non Woven Geotextile Drainage Fabric for Driveway

- Excellent Drainage: Non-woven geotextiles provide high permeability, allowing water to flow freely and preventing water accumulation, which reduces the risk of surface damage.

- Soil Stabilization: The fabric helps to stabilize the soil beneath the driveway, preventing erosion and maintaining the integrity of the subgrade, which is essential for long-term durability.

- Load Distribution: It effectively distributes the weight of vehicles across a wider area, minimizing the formation of ruts and depressions over time.

- Durability: Made from synthetic fibers, non-woven geotextiles are resistant to UV rays, chemicals, and physical degradation, ensuring a long lifespan under various environmental conditions.

- Cost-Effective: The use of non-woven geotextiles can reduce the need for extensive drainage systems, saving on installation and maintenance costs.

- Easy Installation: The lightweight and flexible nature of the fabric makes it easy to handle and install, facilitating a quicker construction process.

Application of Non Woven Geotextile Drainage Fabric for Driveway

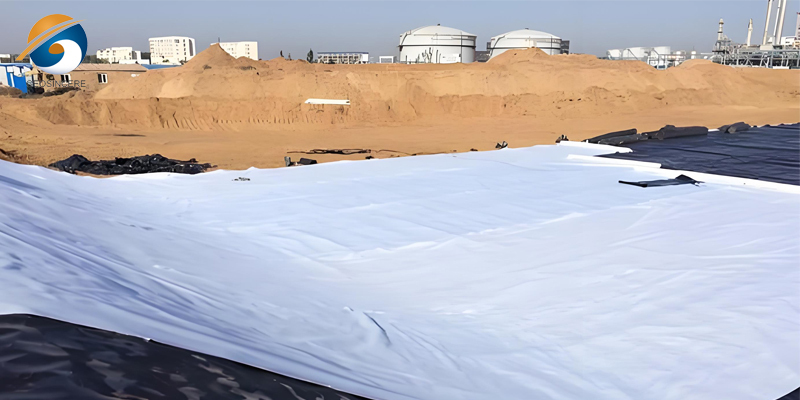

- Subgrade Preparation: The fabric is laid directly on the prepared subgrade before the installation of gravel or asphalt, providing a stable foundation.

- Gravel Driveways: It is commonly used in gravel driveways to prevent the mixing of gravel with the underlying soil, enhancing drainage and stability.

- Paved Driveways: Non-woven geotextiles can be used under asphalt or concrete surfaces to improve drainage and reduce the risk of cracking.

- Erosion Control: The fabric helps to control erosion in areas with steep slopes adjacent to driveways, protecting the integrity of the surface.

- Water Management Systems: It can be integrated into various water management systems, such as French drains, to enhance overall drainage effectiveness.

- Recreational Areas: Non-woven geotextiles are also suitable for driveways in parks or recreational areas, providing stability and preventing surface degradation.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!