High Performance Geotextile Fabric for Road Covering

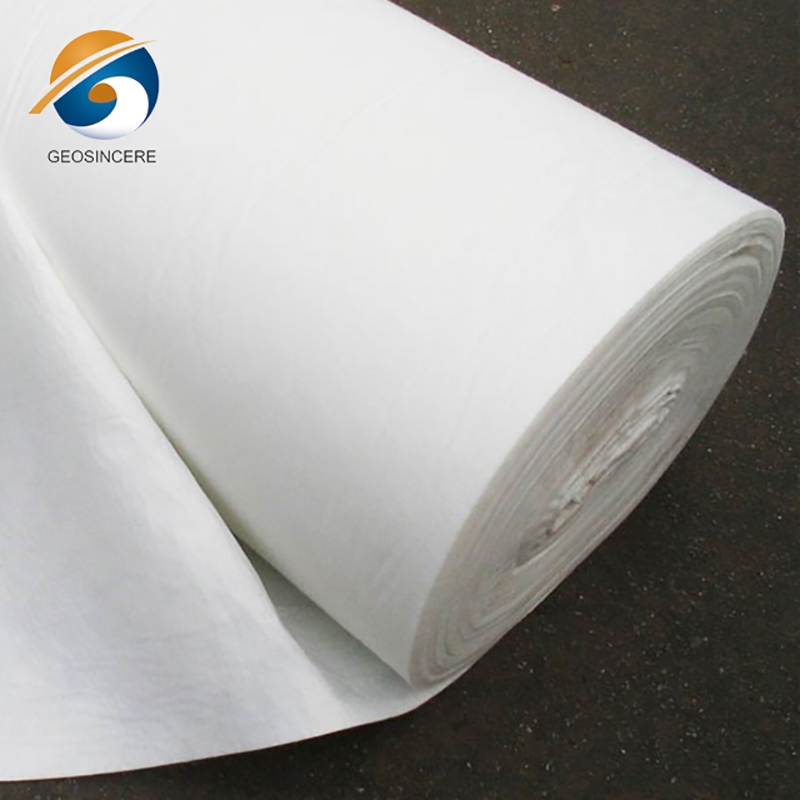

High-performance geotextile materials can be widely used as roadbed covering materials in highway projects. This fabric product has excellent tensile strength, high wear resistance and good water permeability, which can effectively reduce roadbed settlement and improve the overall stability of the highway. During the paving process, high-performance geotextiles can also isolate soil particles between the roadbed and the covering layer, preventing fine particles from entering the pavement layer and causing early damage. At the same time, the excellent water permeability of this material can also help to drain the water accumulated in the roadbed in time, avoiding the problem of freezing and thawing of the road surface caused by water accumulation. Therefore, using high-performance geotextiles as roadbed covering materials in highway projects can effectively improve the service life and reliability of the highway.

High-performance geotextiles are usually woven from high-strength fibers such as nylon and polyester, and have the characteristics of high strength, high modulus, corrosion resistance, and aging resistance. It is widely used in road construction materials. Its main function is to improve the bearing capacity of the roadbed and enhance the crack resistance of the road surface.

During the paving process, it can be used as an isolation layer to effectively block the mutual intrusion between the roadbed and the road surface, thereby extending the service life of the road surface. At the same time, geotextiles can also enhance the shear strength of the soil layer, improve the overall stiffness of the road surface, and reduce the settlement of the road surface.

In addition, high-performance geotextiles can also be used as reinforcing bars, and used in conjunction with cement, asphalt and other materials to improve the tensile and bending resistance of the entire road surface structure. In some soft foundations or earthquake areas, the application of geotextiles is more critical, which can effectively control the deformation of the road surface and ensure traffic safety.

In short, as a high-quality road construction material, high-performance geotextiles play an important role in road engineering. It can not only enhance the structural stability of the road surface, but also effectively extend the service life of the road surface, creating a more comfortable and safe travel environment for people.

Parameter

Item | Test Method | Unit | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

Index Properties | ||||||||||||

Ultimate Tensile Strength. MD | ASTM D4595 | KN/m | 1 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

Ultimate Tensile Strength, TD | ASTM D4595 | KN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Grab Tensile Strength. MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

Grab Tensile Strength, TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Trapezoid Tear Strength. MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

Trapezoid Tear Strength, TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

Apparent Opening Size 090 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Water Flow Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

Weight | ASTM D5261 | G/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

Roll width | / | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

Roll Length | / | m | 300 | 200 | 150 | 100 | 100 | 100 | 80 | 80 | 50 | 50 |

Advantages of High Performance Geotextile Fabric for Road Covering

1. Improve the bearing capacity of the roadbed: Geotextile as an isolation layer can effectively avoid mutual erosion between the roadbed and the road surface, and improve the bearing capacity of the overall roadbed.

2. Enhance the crack resistance of the road surface: Geotextile has high strength and high modulus characteristics, and can form a composite reinforcement with the road surface material, effectively reducing the risk of cracking of the road surface.

3. Extend the service life of the road surface: The isolation and reinforcement of the geotextile can significantly delay the aging and damage of the road surface and extend the service life of the road surface.

4. Control the deformation of the road surface: In soft foundations or earthquake areas, geotextiles can effectively limit the uneven settlement and deformation of the road surface and ensure traffic safety.

5. Wide applicability: Geotextiles are made of various materials, and suitable products can be selected according to different engineering environments to meet the needs of various road projects.

6. Simple and efficient construction: Geotextile laying is convenient and quick, which greatly improves the efficiency of road construction.

In general, high-performance geotextiles have significant advantages in improving the structural performance of the road surface and extending the service life of the road surface, and are an indispensable and important material in road engineering.

Related Applications of High Performance Geotextile Fabric for Road Covering

In addition to being used as a roadbed covering material in highway projects, high-performance geotextiles also have the following related applications:

1. Roadbed reinforcement and stabilization: In weak roadbeds or sections prone to collapse, laying high-strength geotextiles on the roadbed can enhance the bearing capacity of the roadbed and improve the overall stability of the roadbed.

2. Drainage and filtration: High-performance geotextiles have excellent water permeability and can be used as drainage layers for roadbeds and slopes to quickly guide the drainage of accumulated water. At the same time, it can also be used as a filter layer to prevent fine particles from penetrating into the drainage system and ensure the long-term effectiveness of the drainage system.

3. Slope protection and slope reinforcement: The use of geotextiles in highway slopes or slope protection projects can enhance the stability of the slope and resist disasters such as soil erosion and landslides.

4. Isolation and separation: Geotextiles can be used as an isolation and separation layer between the roadbed and the upper pavement layer to prevent fine particles from entering the pavement layer and extend the service life of the road surface. At the same time, it can also be used to isolate the roadbed from the foundation soil to avoid mutual erosion between the two.

It can be seen that high-performance geotextiles have broad application prospects in the field of highway engineering, which can not only improve the structural stability and service life of highways, but also enhance the disaster resistance of highways. Reasonable selection and scientific construction are the key to maximize their effectiveness.

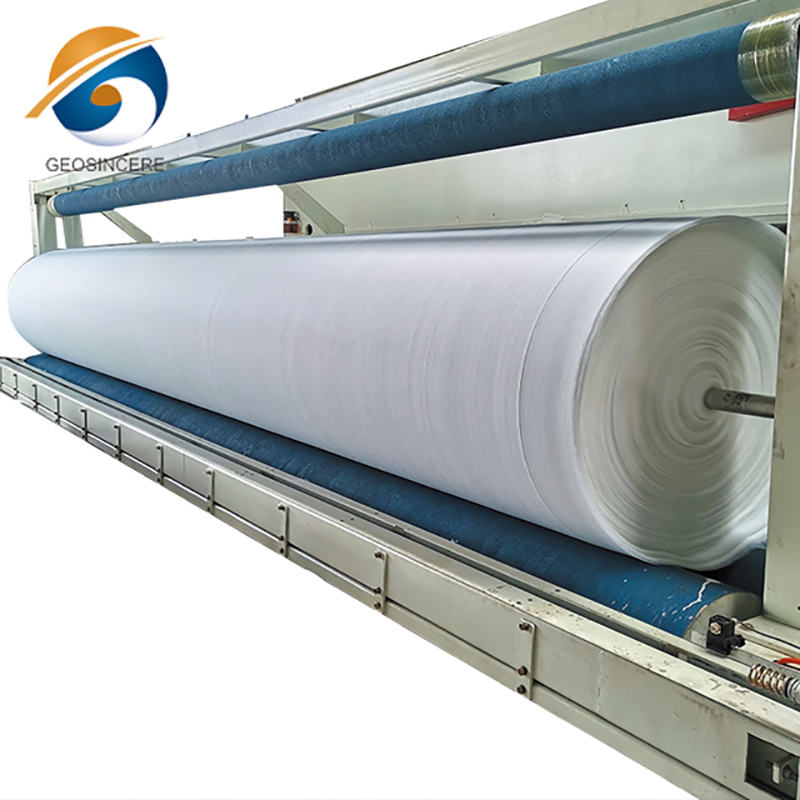

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!