Geotextile Stabilization Fabric

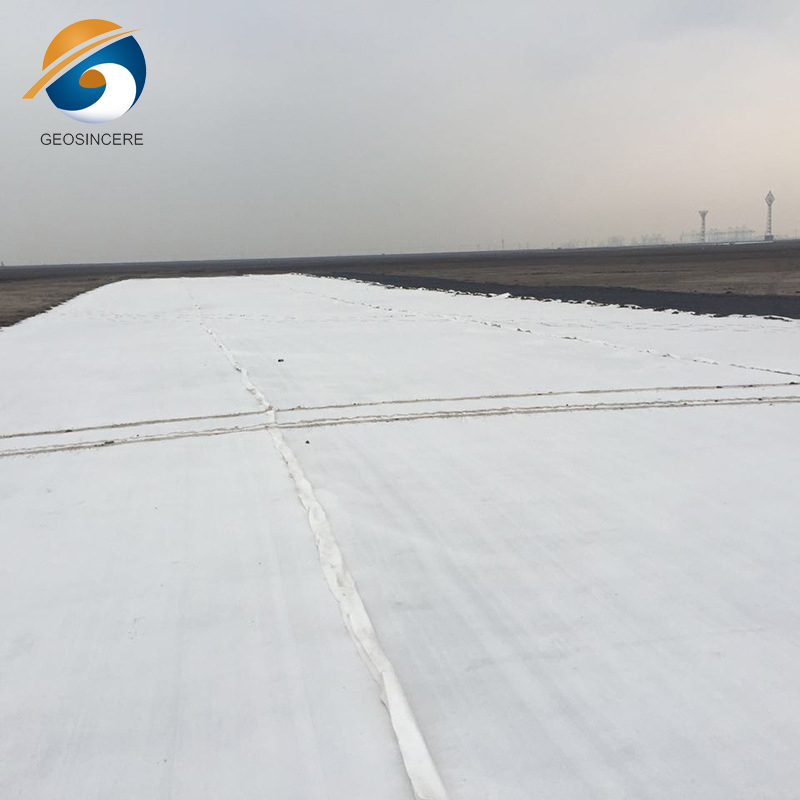

Geotextile stabilization fabric is a versatile and essential material used across various civil engineering and environmental projects. It is designed to enhance soil stability, provide reinforcement, and improve overall infrastructure durability.

Geotextile stabilization fabric is a synthetic, permeable material typically made from polyester or polypropylene. It is engineered to perform multiple functions, including separation, filtration, reinforcement, drainage, and protection. These fabrics are available in woven and non-woven forms, each offering unique benefits depending on the application.

Geotextile stabilization fabric is a cornerstone of modern construction, offering a blend of durability, stability, and environmental sustainability. Its application in highways, driveways, and other infrastructure projects underpins the safety and longevity of these essential pathways.

Geotextile stabilization fabric is an essential component in civil engineering and construction, designed to enhance the stability and durability of soil structures. Made from high-quality synthetic fibers, this fabric provides a permeable barrier that allows water to flow through while preventing soil erosion and sedimentation. Its primary function is to reinforce the ground by distributing loads over a larger area, thus reducing the risk of soil displacement and failure.

The fabric is particularly effective in applications such as road construction, embankments, and retaining walls, where it helps to maintain the integrity of the soil under varying environmental conditions. Available in different types, including woven and non-woven varieties, geotextile stabilization fabric can be selected based on specific project requirements, such as drainage needs or tensile strength.

Moreover, the installation process is straightforward, making it a cost-effective solution for improving soil stability. By incorporating geotextile stabilization fabric into construction projects, engineers can significantly extend the lifespan of structures, minimize maintenance costs, and promote sustainable practices by reducing the environmental impact of soil erosion. Overall, this innovative material plays a crucial role in modern engineering, ensuring safer and more resilient infrastructure.

Parameter

Item | Test Method | Unit | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

Index Properties | ||||||||||||

Ultimate Tensile Strength. MD | ASTM D4595 | KN/m | 1 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

Ultimate Tensile Strength, TD | ASTM D4595 | KN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Grab Tensile Strength. MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

Grab Tensile Strength, TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Trapezoid Tear Strength. MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

Trapezoid Tear Strength, TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

Apparent Opening Size 090 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Water Flow Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

Weight | ASTM D5261 | G/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

Roll width | / | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

Roll Length | / | m | 300 | 200 | 150 | 100 | 100 | 100 | 80 | 80 | 50 | 50 |

Advantages of Geotextile Stabilization Fabric

1. Soil Reinforcement: Geotextile fabrics enhance the load-bearing capacity of soil by distributing loads over a wider area, reducing the risk of soil failure and settlement.

2. Erosion Control: They effectively prevent soil erosion by stabilizing the ground and retaining soil particles, making them ideal for slopes, riverbanks, and other vulnerable areas.

3. Improved Drainage: The permeable nature of geotextile fabrics allows for efficient water drainage while filtering out sediment, which helps maintain the integrity of the soil structure.

4. Cost-Effectiveness: By reducing the need for extensive excavation or additional materials, geotextile fabrics can lower overall project costs while enhancing performance.

5. Versatility: Available in various types (woven, non-woven, and knitted), geotextile fabrics can be tailored to suit a wide range of applications, from road construction to landscaping.

6. Durability: Made from robust synthetic materials, geotextile stabilization fabrics are resistant to rot, UV degradation, and chemical exposure, ensuring long-lasting performance.

7. Ease of Installation: The lightweight nature of geotextile fabrics simplifies transportation and installation, allowing for quicker project completion.

8. Sustainability: By minimizing soil erosion and promoting vegetation growth, geotextile fabrics contribute to environmental preservation and sustainable land management practices.

9. Enhanced Performance of Aggregate Layers: When used in conjunction with aggregates, geotextile fabrics improve the overall performance of gravel and other base materials, reducing the need for frequent repairs.

10. Environmental Protection: They act as barriers against contaminants, helping to protect groundwater and surrounding ecosystems from harmful substances in construction sites.

Application of Geotextile Stabilization Fabric

1. Road Construction: Geotextile fabrics are widely used in road construction to reinforce subgrade soils, enhance load distribution, and prevent rutting. They help maintain the structural integrity of the road, reducing maintenance costs over time.

2. Erosion Control: These fabrics are effective in preventing erosion on slopes, riverbanks, and coastal areas. They stabilize soil while allowing water to drain, thus minimizing washout during heavy rainfall.

3. Landfill Projects: In landfill applications, geotextiles act as barriers to separate waste materials from the surrounding soil, preventing leachate contamination. They also help in drainage and managing groundwater.

4. Retaining Walls: Geotextile fabrics are utilized in the construction of retaining walls to provide stability and support. They help distribute lateral earth pressures and contribute to the overall strength of the wall structure.

5. Slope Stabilization: In areas prone to landslides or soil slippage, geotextile fabrics can be used to reinforce slopes, enhancing soil cohesion and reducing the risk of failure.

6. Drainage Systems: Geotextile fabrics are essential in drainage applications, such as in French drains or underdrain systems. They filter out sediment while allowing water to pass through, preventing clogging of drainage materials.

7. Pavement Design: In flexible pavement systems, geotextiles help separate the base course from the subgrade, preventing mixing and enhancing the lifespan of the pavement.

8. Construction of Green Roofs: Geotextile fabrics are used in green roof systems to support vegetation while providing drainage and aeration, thus promoting healthy plant growth.

9. Stabilization of Aggregates: When used beneath gravel or crushed stone layers, geotextile fabrics help prevent movement and mixing with the underlying soil, maintaining the integrity and effectiveness of the aggregate layer.

10. Infrastructure Rehabilitation: Geotextiles are applied in the rehabilitation of existing infrastructures, such as bridges and pavements, to enhance their load capacity and extend their service life.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!