What is Geo Clay Liner Used for?

Geo clay liner is innovative solutions designed to provide effective barriers against fluid migration in various environmental applications. These liners, composed of compacted clay and geosynthetic materials, are primarily used in landfills, waste containment systems, and environmental remediation projects. Their unique properties offer exceptional impermeability, making them ideal for preventing leachate and contaminants from penetrating soil and groundwater. By incorporating geo clay liners, you can enhance the integrity of your containment systems, ensuring long-term environmental protection and compliance with regulatory standards.

1. What Is a Geo Clay Liner and How Does It Work?

A geo clay liner is a composite material made from natural clay and geosynthetic components, designed to create an effective impermeable barrier. It is primarily used in environmental applications such as landfills, waste containment systems, and mining operations. The product functions by leveraging the low permeability of clay, combined with the structural support of geosynthetics, to prevent the migration of leachate and contaminants into surrounding soil and groundwater. This innovative solution not only enhances the environmental safety of containment sites but also complies with regulatory requirements, ensuring long-term protection against pollution.

Composition

- Bentonite Clay: This is a natural clay material with excellent swelling and sealing properties. When hydrated, it expands and forms a barrier against liquids.

- Geotextiles: These are permeable fabrics that provide strength and stability, helping to contain the bentonite and prevent it from being washed away.

2. What Are the Benefits of Using Geo Clay Liner?

2.1 Effective Sealing

- Waterproof Barrier: GCLs provide a strong barrier against water and leachate, preventing contamination of groundwater.

2.2 Cost-Effective

- Lower Installation Costs: Often cheaper than traditional clay liners due to reduced material and labor requirements.

2.3 Lightweight and Flexible

- Easy Handling: GCLs are lighter than conventional alternatives, making them easier to transport and install.

2.4 Environmental Protection

- Contamination Prevention: They help in containing hazardous materials, minimizing the risk of soil and water pollution.

2.5 Durability

- Robust Design: The outer layers protect the bentonite from physical damage, ensuring longevity.

2.6 Quick Installation

- Efficient Setup: GCLs can be installed quickly, reducing project timelines.

2.7 Versatility

- Multiple Applications: Suitable for landfills, mining, reservoirs, and various environmental projects.

2.8 Hydration Activation

- Self-Sealing Properties: When hydrated, bentonite expands to seal gaps, enhancing effectiveness.

2.9 Reduced Maintenance

- Lower Upkeep Needs: Once installed, GCLs generally require less maintenance compared to other systems.

2.10 Sustainability

- Natural Materials: Composed primarily of natural clay, GCLs are an environmentally friendly choice.

3. What Is the Purpose of a Geo Clay Liner?

3.1 Containment

- Hazardous Waste: GCLs are used to contain hazardous materials in landfills and waste storage facilities, preventing leachate from contaminating the surrounding environment.

3.2 Waterproofing

- Groundwater Protection: They act as a waterproof barrier in applications like reservoirs and ponds, minimizing seepage and protecting groundwater sources.

3.3 Sealing

- Natural Sealant: The bentonite clay expands when wet, providing a self-sealing mechanism that effectively blocks water and other fluids.

3.4 Stability Enhancement

- Soil Reinforcement: GCLs can enhance the stability of structures by providing additional support in soil and geological applications.

3.5 Environmental Protection

- Pollution Prevention: They help mitigate the risk of soil and water contamination from industrial activities and waste disposal.

3.6 Slope Stabilization

- Erosion Control: Used in civil engineering projects to stabilize slopes and prevent erosion in areas susceptible to water runoff.

3.7 Cost Efficiency

- Alternative to Traditional Liners: GCLs provide an effective and often more economical alternative to traditional clay liners in various applications.

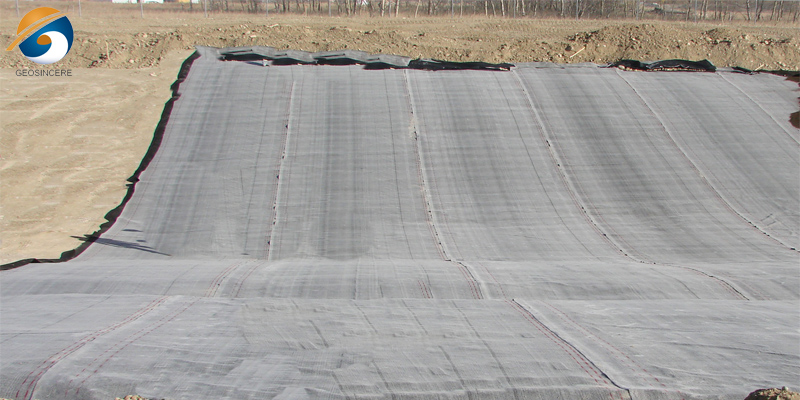

4. How Is a Geo Clay Liner Installed?

4.1 Site Preparation

- Clearing the Area: Remove any vegetation, debris, and sharp objects from the installation site to provide a smooth surface.

- Grading: Level the ground to create a stable base for the GCL.

4.2 Geotextile Placement

- Roll Out the GCL: Unroll the GCL over the prepared surface, ensuring it is laid out flat without any folds or wrinkles.

4.3 Seam Overlapping

- Overlap Sections: If multiple rolls are used, overlap the seams by at least 12 inches (30 cm) to ensure a continuous barrier. This prevents water from seeping through gaps.

4.4 Securing the GCL

- Anchoring: Use stakes or other anchoring methods to hold the GCL in place, especially on slopes or windy conditions.

4.5 Hydration

- Activate Bentonite: Hydrate the bentonite clay by applying water uniformly across the surface. This is crucial for activating its swelling properties, which enhance sealing.

4.6 Compaction

- Compact the Surface: If required, compact the GCL to ensure good contact with the underlying soil and to eliminate air pockets.

4.7 Covering

- Install Protective Layers: In some applications, a protective layer of soil or a geomembrane may be placed over the GCL to shield it from physical damage and environmental factors.

4.8 Final Inspection

- Check for Integrity: Inspect the installation for any gaps, tears, or improper overlaps, making necessary repairs before the final covering.

4.9 Monitoring

- Post-Installation Checks: After installation, monitor the GCL for performance and integrity, especially in the initial phases.

5. Summary

Geo clay liners play a crucial role in environmental protection and engineering by preventing leakage, containing hazardous materials, and ensuring the safety of groundwater and soil.