What Are The Advantages of Using HDPE Geomembrane in Aquaculture?

HDPE (high-density polyethylene) geomembranes are widely used in aquaculture. With their excellent anti-seepage, drainage and weather resistance properties, they are widely favored by the aquaculture industry and have become the preferred material for building safe, efficient and environmentally friendly aquaculture ponds. Aquaculture companies can give full play to the advantages of HDPE geomembranes to create more reliable and energy-saving aquaculture facilities, effectively protect the aquaculture environment, improve aquaculture efficiency and product quality, and promote the sustainable development of the industry. Read this article to learn more about the unique advantages of using geomembranes for aquaculture.

1. What is HDPE geomembrane?

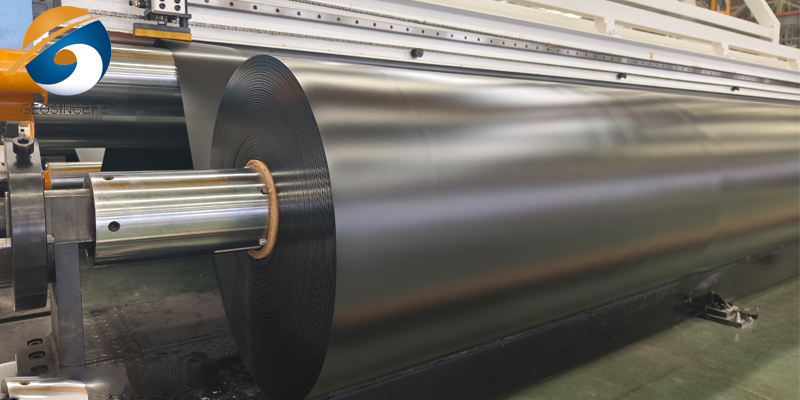

HDPE Geomembrane is a waterproof and anti-leakage material made of polyethylene, which is widely used in various engineering construction. It has excellent tensile strength, chemical corrosion resistance, aging resistance and low temperature resistance, and plays an irreplaceable role in infrastructure construction such as agriculture, aquaculture, landfills, reservoirs, etc. HDPE geomembrane is usually between 0.2-2.5 mm thick, with a flat and smooth surface, which can fit the construction base well to ensure the anti-leakage effect. Its unique material properties enable it to resist erosion from various environmental factors, such as sunlight, acid and alkali corrosion, freeze-thaw cycles, etc., thereby ensuring the long-term safety and stability of the entire engineering structure.

In addition, HDPE geomembrane also has good recyclability, which helps to promote the recycling of construction waste and reduce the load on the environment. In short, HDPE geomembrane, as a high-quality anti-seepage material, has become an indispensable and important part of various infrastructure construction.

2.What is The Unique Function of Geomembrane Preventing Leakage in Aquaculture Ponds?

2.1 Excellent waterproof performance

HDPE geomembrane has uniform thickness, smooth surface, and extremely low permeability to water and other liquids, ensuring effective barrier to penetration.

2.2 Strong chemical corrosion resistance

Some acidic and alkaline wastewater will be produced during aquaculture. HDPE material has strong resistance to various chemicals, acids, alkalis and other substances, and can resist the erosion of these harmful substances for a long time, ensuring that the membrane maintains its integrity in the aquaculture environment.

2.3 Good durability

HDPE geomembrane has excellent mechanical strength, tear resistance, and resistance to UV radiation and weathering. This enables it to withstand the pressure and environmental factors in outdoor aquaculture ponds for a long time, which is crucial for the sustainability of the anti-seepage effect

2.4 Strong installation convenience

The construction process of HDPE geomembrane is simple and fast, and can be customized according to different pond size specifications, and reliable joint processing can be achieved through welding and other methods to ensure the airtightness of the entire anti-seepage system.

These unique properties of HDPE geomembranes make them ideal for lining aquaculture ponds and tanks, providing a strong, durable, water-tight barrier. This helps maintain water quality, prevent contamination, and ensure the overall integrity of the aquaculture system.

3. How To Choose The Right Geomembrane Material in Aquaculture Pond Construction?

3.1 Chemical resistance:

- Geomembranes must be able to resist chemicals and organic compounds commonly found in aquaculture ponds, such as fish waste, algae, and various water treatments.

- Commonly used geomembrane materials include high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and polyvinyl chloride (PVC). They have excellent chemical resistance.

3.2 Durability and service life:

- Geomembranes should have sufficient tensile strength, tear resistance, and UV resistance to withstand the harsh pond environment and the expected use time.

- HDPE and LLDPE are generally more durable and have a longer service life (20-30 years) compared to PVC (10-15 years).

3.3 Thermal stability:

- Geomembranes should be able to withstand the temperature fluctuations encountered in pond environments, ranging from freezing to high summer temperatures.

- HDPE and LLDPE have better thermal stability than PVC.

3.4 Puncture and tear resistance:

- Geomembranes must be able to withstand potential punctures and tears from a variety of sources, such as sharp objects, burrowing organisms, and installation equipment.

- Materials with high tensile strength and puncture resistance, such as textured HDPE or reinforced geomembranes, are generally preferred.

3.5 Thickness and density:

- The thickness and density of a geomembrane can affect its overall performance and durability.

- Thicker and denser materials tend to be more resistant to punctures, tears, and environmental stresses, but they may also be more expensive.

3.6 Flexibility and ease of installation:

- Geomembranes should be flexible enough to adapt to the varying topography and contours of a pond site, making them easier to install and reducing the risk of wrinkling or folding.

- Flexible PVC, for example, may be better suited to irregular pond shapes and uneven terrain.

3.7 Seam strength:

- Geomembrane seams should be able to maintain their integrity and prevent leaks, as ponds require a continuous, impermeable barrier.

- Heat-welded seams are generally stronger and more reliable than chemically bonded seams.

Based on these factors, HDPE and LLDPE are generally the most suitable geomembrane materials for aquaculture pond construction, providing a good balance of chemical resistance, durability, and thermal stability.

4. Application Cases of HDPE Geomembrane in Aquaculture?

4.1 Aquaculture Ponds:

- HDPE geomembranes are widely used as pond liners for freshwater and saltwater aquaculture facilities such as fish farms, shrimp ponds, and hatcheries.

- HDPE's high chemical resistance and durability make it ideal for preventing leaks, controlling water quality, and maintaining pond integrity.

4.2 Aquaculture Ponds and Tanks:

- HDPE geomembranes are used as liners for indoor and outdoor aquaculture ponds, tanks, and other enclosures.

- HDPE's smooth, non-porous surface allows for easy cleaning and maintenance, and its durability ensures long-term performance.

4.3 Aquaculture Reservoirs and Cisterns:

- HDPE geomembranes are used as liners for reservoirs and cisterns that store water for aquaculture operations such as water supply, temperature regulation, and emergency backup.

- HDPE's excellent sealing properties prevent water loss and maintain the required water level.

4.4 Aquaculture Nurseries and Hatcheries:

- HDPE geomembranes are used as liners in nursery and hatchery facilities where a controlled environment is essential for the growth and development of aquatic species.

- HDPE’s chemical resistance and easy cleanability make it a suitable choice for these sensitive aquaculture applications.

4.5 Aquaculture Waste Control:

- HDPE geomembranes are used to cover ponds or lagoons for the storage and treatment of aquaculture waste, such as fish mud and pond sediment.

- The impermeability of HDPE helps prevent contaminants from leaching into the surrounding environment.

The versatility, durability, and chemical resistance of HDPE geomembranes make them a top choice for a wide range of aquaculture applications, helping to manage aquaculture operations efficiently and sustainably.

5. Summarize

HDPE (High Density Polyethylene) geomembranes have a variety of wide applications in aquaculture. As a material with strong chemical resistance and good durability, HDPE geomembranes are widely used for anti-seepage and water quality protection in aquaculture ponds. It can be used for lining ponds, tanks and aquaculture cages to provide a stable isolation environment for aquaculture water bodies and prevent water quality from being polluted by the outside world. HDPE geomembranes have become an indispensable and important material in the aquaculture industry, playing a key role in the construction and management of the entire aquaculture system.