HDPE Geomembrane 2mm

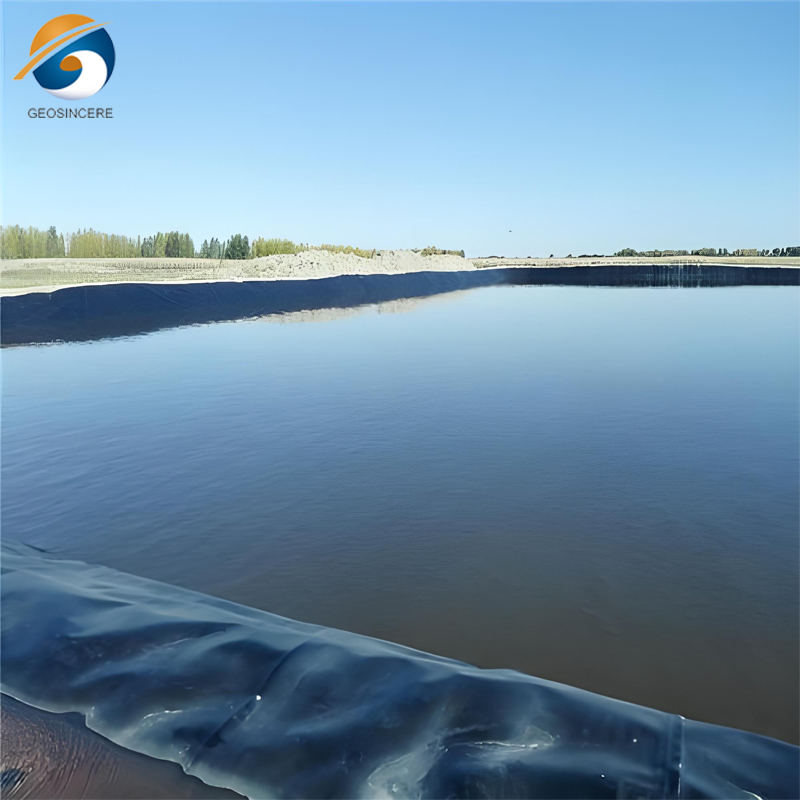

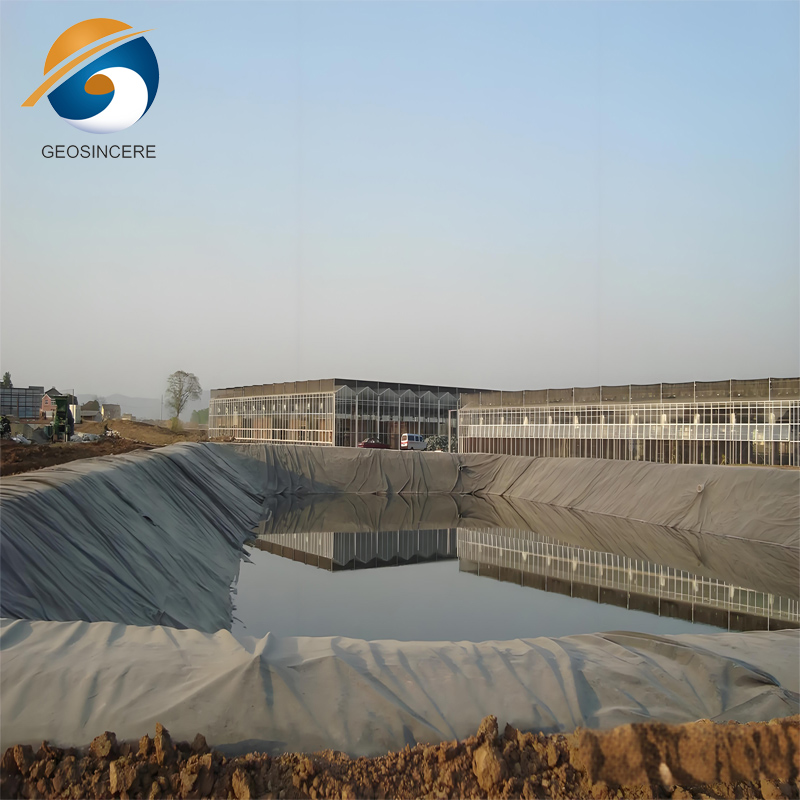

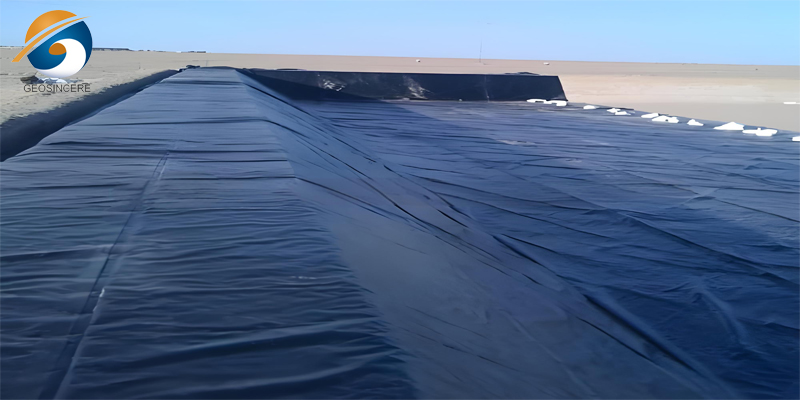

HDPE geomembrane 2mm, with a thickness of 2mm, is a robust and versatile liner material commonly used in various environmental and engineering applications. This geomembrane is known for its exceptional strength, chemical resistance, and impermeability, making it an ideal choice for projects such as landfills, containment ponds, and wastewater treatment facilities. The 2mm thickness provides an optimal balance of durability and flexibility, allowing it to withstand harsh environmental conditions while maintaining its structural integrity. HDPE geomembranes are engineered to resist UV radiation, punctures, and environmental stress, ensuring long-term performance and reliability. Furthermore, the ease of installation and the ability to weld seams create a seamless barrier, significantly reducing the risk of leaks. With its outstanding performance characteristics, 2mm HDPE Geomembrane is a preferred solution for projects requiring effective containment and environmental protection.

The HDPE geomembrane with a thickness of 2mm is a highly durable and effective barrier material widely utilized in various applications, including landfills, waste containment, and environmental protection projects. Its high-density polyethylene composition provides excellent resistance to chemicals, UV radiation, and mechanical stress, making it suitable for both above-ground and below-ground installations. The 2mm thickness strikes a perfect balance between flexibility and strength, allowing it to conform to uneven surfaces while maintaining its integrity under extreme conditions. One of the key advantages of HDPE geomembranes is their impermeability, which prevents the migration of liquids and contaminants, thereby protecting the surrounding environment. Additionally, the geomembrane can be easily welded to create seamless joints, minimizing the risk of leaks and ensuring a reliable barrier. With its long service life and low maintenance requirements, the 2mm HDPE geomembrane is an ideal choice for engineers and environmental professionals seeking a robust solution for effective containment and sustainable project outcomes.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Geomembrane 2mm Features

- High Durability: The 2mm thickness of HDPE geomembrane ensures outstanding strength and resistance to punctures, tears, and environmental stressors, making it suitable for demanding applications.

- Chemical Resistance: This geomembrane effectively withstands a wide range of chemicals, including acids, bases, and solvents, ensuring reliable performance in various containment scenarios.

- Impermeability: HDPE geomembranes provide excellent impermeability, preventing the migration of liquids and contaminants, which is crucial for protecting soil and groundwater.

- UV Resistance: Enhanced resistance to ultraviolet radiation ensures that the material maintains its integrity and performance even when exposed to sunlight over extended periods.

- Flexibility and Conformability: Despite its strength, the 2mm HDPE geomembrane remains flexible, allowing it to adapt to uneven surfaces and complicated site conditions, ensuring a proper fit.

- Seamless Joints: The geomembrane can be easily welded to create seamless joints, significantly reducing the risk of leaks and enhancing overall containment effectiveness.

- Low Maintenance: Once installed, HDPE geomembranes require minimal maintenance, resulting in long-term cost savings and reduced operational concerns.

- Environmental Protection: By preventing contaminant migration, the geomembrane plays a crucial role in protecting the environment, making it an essential component in sustainable engineering practices.

- Versatile Applications: Suitable for various applications such as landfill liners, mining, aquaculture, and wastewater treatment, the 2mm HDPE geomembrane is a versatile solution for many engineering challenges.

Applications of HDPE Geomembrane 2mm

- Landfill Liners: HDPE geomembranes are extensively used as liners in landfills to prevent leachate from contaminating surrounding soil and groundwater, providing a reliable barrier against pollutants.

- Wastewater Treatment: In wastewater treatment facilities, the 2mm HDPE geomembrane serves as a containment layer to manage and contain effluents, ensuring that any potential leaks are effectively controlled.

- Mining Operations: The geomembrane is employed in mining applications for tailings storage and heap leach pads, where it prevents the seepage of hazardous materials into the environment, safeguarding local ecosystems.

- Containment Ponds: Used in various industries, including agriculture and chemical processing, HDPE geomembranes line containment ponds to hold liquids safely, preventing leaks and environmental contamination.

- Aquaculture: In aquaculture systems, the 2mm HDPE geomembrane is utilized to line fish ponds and tanks, ensuring water retention and maintaining a controlled aquatic environment.

- Irrigation and Water Reservoirs: HDPE geomembranes are ideal for lining irrigation canals and water reservoirs, minimizing water loss through seepage and enhancing water conservation efforts.

- Oil and Gas Applications: The geomembrane is used in oil and gas industries for spill containment and secondary containment systems, effectively managing any hazardous material spills.

- Capping Systems: In closed landfills, HDPE geomembranes are employed as part of capping systems to cover waste, preventing water infiltration and minimizing the release of gases.

- Construction Projects: HDPE geomembranes are also used in various construction projects to provide temporary containment solutions, ensuring environmental protection during excavation and site preparation.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrana and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembana, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrana research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembrana and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembrana and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembrana and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!