Geomembrane HDPE Liner Cost Per m2

High density polyethylene (HDPE) anti-seepage film is a high-quality anti-seepage material widely used in various environmental engineering projects. It is made of high-density polyethylene resin and has excellent chemical corrosion resistance, water penetration resistance and aging resistance. HDPE anti-seepage film can be widely used as an anti-seepage isolation layer in construction projects such as landfills, reservoirs, water channels, tunnels, and artificial lakes, providing reliable anti-seepage solutions for these projects. HDPE anti-seepage film has good hot melt weldability, which can be reliably laid and jointed through hot melt welding technology to avoid leakage. In addition, HDPE anti-seepage film itself is lightweight, has strong tear resistance, and strong resistance to UV aging, making its installation and construction operation simple and fast, and can also play a lasting anti-seepage and isolation role in harsh environmental conditions. In short, HDPE anti-seepage membrane is widely favored by the industry for its excellent performance characteristics and plays an irreplaceable and important role in various anti-seepage projects.

High density polyethylene (HDPE) anti-seepage film is an artificial barrier material widely used in the field of environmental engineering. It is known for its excellent chemical resistance, cold resistance, UV resistance, and outstanding mechanical properties, and is widely used for anti leakage protection in structures such as landfills, reservoirs, and ponds. HDPE anti-seepage film is usually made of products with a thickness between 0.5-2.0 millimeters, which can be customized according to engineering requirements. It has an extremely low permeability coefficient, usually less than 10-9 cm/s, which can effectively block the penetration of liquids and gases and meet the anti leakage requirements of various environmental engineering. The construction of HDPE anti-seepage film is simple and fast, and the connection methods include hot melt welding, bonding, etc., which can adapt to complex construction environments. It is widely used in urban solid waste landfills, mine tailings ponds, reservoirs, and anti-seepage canals, playing an important role in environmental protection. With the continuous advancement of technology, the performance of HDPE anti-seepage film is also constantly optimized and improved, laying a solid foundation for more extensive and in-depth environmental applications.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Advantages of Geomembrane HDPE Liner Cost Per m2

HDPE (High-Density Polyethylene) Geomembrane liners offer several advantages when it comes to cost per square meter (m2):

1. Cost-Effectiveness:

- HDPE is a relatively inexpensive raw material compared to other geosynthetic materials, making the overall production cost of HDPE geomembranes lower.

- The manufacturing process for HDPE geomembranes is also more efficient and cost-effective compared to some alternative materials.

2. Durability and Longevity:

- HDPE geomembranes have an exceptionally long service life, often exceeding 50 years when properly installed and maintained.

- This long-term durability helps to spread the initial installation cost over the lifetime of the project, making the cost per m2 more economical.

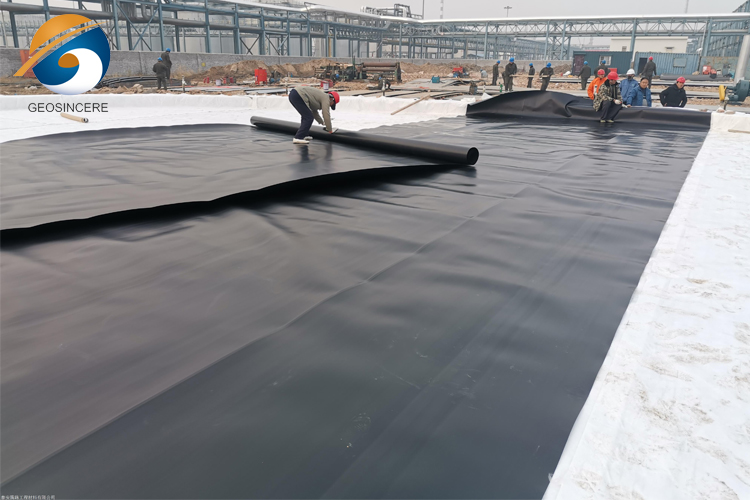

3. Efficient Installation:

- HDPE geomembranes are lightweight and easy to transport, reducing the costs associated with transportation and handling.

- The welding process for HDPE geomembranes is relatively straightforward, which can lead to faster installation and lower labor costs.

4. Minimal Maintenance:

- HDPE geomembranes require minimal maintenance compared to some other geosynthetic materials, further reducing the long-term costs associated with the liner.

5. Versatility and Reusability:

- HDPE geomembranes can be used in a wide range of applications, from landfills and ponds to reservoirs and canals, allowing for economies of scale and reduced costs per project.

- In some cases, HDPE geomembranes can be removed and repurposed for other projects, further enhancing the cost-effectiveness.

Overall, the combination of low raw material costs, efficient manufacturing, easy installation, and long-term durability makes HDPE geomembranes a highly cost-effective solution for various environmental and civil engineering projects, with a relatively low cost per square meter.

Application of Geomembrane HDPE Liner Cost Per m2

Geomembrane HDPE (High-Density Polyethylene) liners have a wide range of applications where their cost-effectiveness per square meter (m2) is a key factor. Here are some of the common applications and the factors that contribute to their cost-effectiveness:

1. Landfill Lining:

- HDPE geomembranes are extensively used as the primary barrier in landfill liners to prevent the leakage of leachate and the migration of contaminants.

- The long lifespan of HDPE geomembranes (often exceeding 50 years) helps to spread the initial installation cost over the entire lifetime of the landfill.

- The cost-effective nature of HDPE geomembranes makes them a preferred choice for large-scale landfill projects, where the total area covered can be substantial.

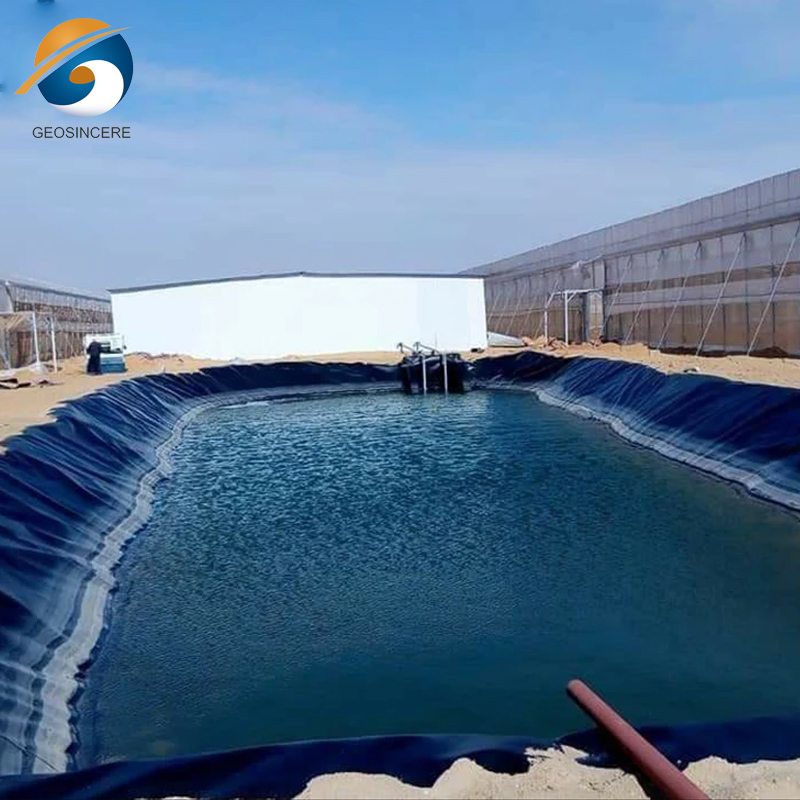

2. Pond and Reservoir Lining:

- HDPE geomembranes are commonly used to line artificial ponds, lakes, and reservoirs to prevent water seepage and loss.

- The durability and resistance of HDPE geomembranes to various environmental factors, such as UV exposure and chemical attack, make them a long-lasting and cost-effective solution.

- The ease of installation and the potential for reuse in multiple projects further contribute to the cost-effectiveness of HDPE geomembranes in these applications.

3. Mining and Industrial Applications:

- HDPE geomembranes are often used in mining operations, such as tailings ponds and heap leach pads, to contain and isolate hazardous materials.

- The cost-effectiveness of HDPE geomembranes is particularly important in these large-scale industrial projects, where the total area covered can be extensive.

- The versatility of HDPE geomembranes allows them to be used in a variety of mining and industrial applications, leading to economies of scale and reduced costs per project.

4. Canals and Water Conveyance:

- HDPE geomembranes are employed to line irrigation canals, drainage ditches, and other water conveyance structures to prevent water seepage and loss.

- The cost-effectiveness of HDPE geomembranes is a key factor in these applications, as the total covered area can be significant, and the cost per square meter directly impacts the overall project budget.

Overall, the combination of a relatively low raw material cost, efficient manufacturing processes, and long-term durability makes HDPE geomembranes a highly cost-effective solution for a wide range of environmental and civil engineering applications, where the cost per square meter is a critical consideration.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrana and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembana, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrana research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembrana and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembrana and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembrana and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!