Erosion Control HDPE Typar Geocell Material for Road

HDPE (High-Density Polyethylene) geocells are commonly used in erosion control and road construction applications. Geocells are three-dimensional cellular structures made from HDPE panels that are connected together to form a grid-like system. These geocells are then filled with soil, aggregate, or other infill materials to create a stable and reinforced structure.HDPE geocells are highly resistant to chemical degradation and environmental factors such as ultraviolet (UV) radiation. They have a long service life and can withstand harsh weather conditions, making them suitable for long-term erosion control applications.

HDPE geocells offer a cost-effective and environmentally friendly solution for erosion control in road construction. They provide stability, load-bearing capacity, and protection against erosion, making them a valuable tool in promoting sustainable infrastructure development.

HDPE (High-Density Polyethylene) geocells are widely used in erosion control for road construction projects. Geocells are three-dimensional cellular confinement systems made from HDPE panels. These panels are connected together to form a grid-like structure, which is then filled with soil, aggregate, or other infill materials.Geocells provide effective soil stabilization by confining and reinforcing the infill material. The interconnected cells create a stable structure that prevents soil erosion and helps maintain the integrity of road embankments or slopes.

Geocells are particularly beneficial for protecting slopes from erosion. They enhance the shear strength of the soil and prevent slope failure by confining the infill material and increasing its resistance to erosion caused by water flow.Geocells distribute loads more evenly across the road surface and subgrade. By confining the infill material, they enhance the load-bearing capacity of the road and reduce the stress on the underlying layers. This leads to improved structural integrity and longevity of the road.

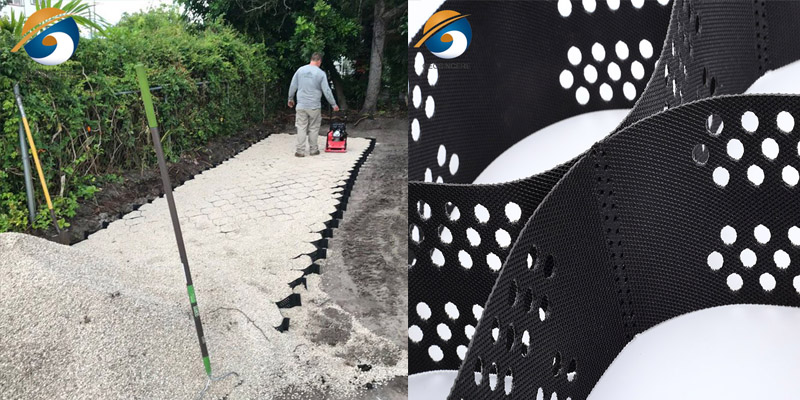

HDPE geocells have a perforated design that allows for proper water drainage. They facilitate the flow of water through the cells, preventing the accumulation of water and reducing the risk of water-related damage, such as erosion and saturation of the roadbed.HDPE geocells are highly durable and resistant to environmental factors such as UV radiation, chemicals, and biological degradation. They can withstand long-term exposure to harsh weather conditions, ensuring a prolonged service life and cost-effective erosion control solution for road projects.

Geocells are lightweight and easy to install, making them a convenient choice for erosion control in road construction. They can be quickly deployed and filled with the desired infill material, reducing construction time and costs.By using HDPE geocells for erosion control in road construction, engineers and contractors can effectively address erosion issues, improve road stability, and enhance the overall performance and longevity of the road infrastructure.

Parameter

Product Type | Height (mm) | Welding Distance (mm) | Thickness (mm) | Tensile Strength of Welding Points (N/cm) | Tensile Strength of Connection of Cells (N/cm) | Tensile Strength at Yield of Each Sheet (MPa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Erosion Control HDPE Typar Geocell Material for Road for Road Features

HDPE (High-Density Polyethylene) geocells for erosion control in road construction offer several important features:

1. Cellular Structure: HDPE geocells are three-dimensional structures with interconnected cells. This design provides a stable framework that helps confine and reinforce the infill material, preventing soil erosion and maintaining the integrity of the road.

2. Load Distribution: Geocells distribute the loads exerted on the road surface more evenly across the infill material and subgrade. This improves load-bearing capacity and reduces stress on the underlying layers, enhancing the road's structural integrity and longevity.

3. Soil Stabilization: Geocells effectively stabilize the soil by confining the infill material within the cells. This prevents lateral movement of the soil particles, reducing the risk of erosion caused by water flow or traffic loads.

4. Erosion Resistance: The interconnected cells of geocells create a barrier that inhibits erosion. They reduce the velocity of water runoff and promote filtration, preventing soil particles from being washed away and maintaining slope stability.

5. Water Drainage: HDPE geocells have perforations or openings in the cell walls, allowing for proper water drainage. This helps prevent the accumulation of water within the structure, reducing the risk of saturation and maintaining the road's stability.

6. Durability: Geocells made from HDPE are highly durable and resistant to chemical degradation, UV radiation, and biological attacks. They have a long service life and can withstand harsh environmental conditions, ensuring reliable erosion control for road applications.

7. Construction Efficiency: HDPE geocells are lightweight and easy to handle, making them convenient for installation. They can be quickly deployed and filled with the desired infill material, reducing construction time and costs.

By utilizing HDPE geocells for erosion control in road construction, engineers and contractors can effectively mitigate erosion, enhance stability, and promote the longevity of the road infrastructure.

Applications of Erosion Control HDPE Typar Geocell Material for Road

Erosion control HDPE geocell material, also known as cellular confinement systems, is a three-dimensional honeycomb-like structure made from high-density polyethylene (HDPE). It has a wide range of applications in erosion control and soil stabilization. Here are some of the common applications:

1. Slope Protection: Geocells are used to stabilize slopes and prevent erosion on embankments, hillsides, and steep slopes. When filled with soil or aggregate, they create a stable structure that reinforces the slope, prevents soil movement, and reduces the risk of landslides.

2. Retaining Walls: Geocells can be used in the construction of retaining walls to enhance their stability and prevent soil erosion behind the walls. The cells are filled with granular material, such as soil or crushed stone, creating a reinforced mass that adds strength and durability to the wall.

3. Channel and Riverbank Protection: Geocells are effective in protecting riverbanks, shorelines, and channels from erosion. They provide a stable structure that can withstand water flow and wave action, reducing the likelihood of bank collapse and erosion.

4. Road and Railway Construction: Geocells are used in road and railway construction to improve the load-bearing capacity of the subgrade and prevent soil movement and rutting. They distribute the load more evenly, reducing the stress on the soil and enhancing the overall stability of the pavement.

5. Vegetated Slopes: Geocells can be filled with soil and planted with vegetation to create green slopes. The cells provide structural support and prevent soil erosion while promoting vegetation growth. Vegetated geocell slopes are commonly used in landscaping, highway beautification, and ecological restoration projects.

6. Landfill Capping: Geocells are used in landfill capping systems to prevent soil erosion and control stormwater runoff. They provide a protective layer that stabilizes the final cover material and minimizes the risk of leachate migration and erosion on the landfill surface.

7. Mining and Coastal Erosion Control: Geocells are employed in mining operations and coastal areas to stabilize the soil and prevent erosion. They can be used to create terraces or berms, control sediment runoff, and protect sensitive ecosystems from erosion caused by mining activities or coastal processes.

Overall, erosion control HDPE geocell material offers a versatile and effective solution for various erosion control and soil stabilization applications. Its use can help minimize environmental impacts, enhance the durability of structures, and promote sustainable development practices.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!