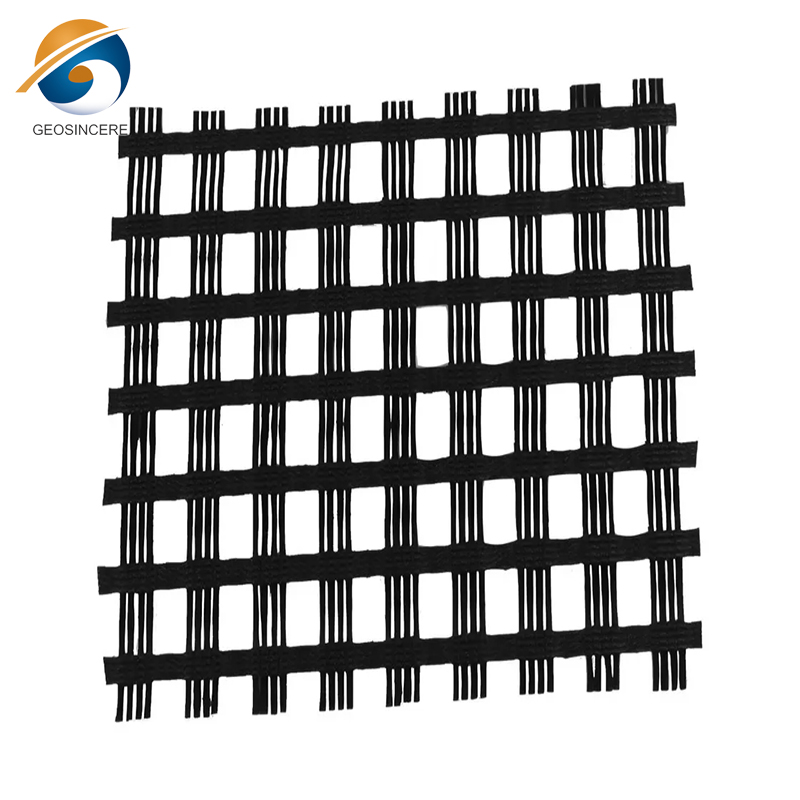

Reinforcement Composite Fiberglass Geogrid for Retaining Wall

Reinforcement Composite Fiberglass Geogrid for Retaining Wall is a composite material grid, mainly composed of glass fiber and polymer materials, and is widely used in soil reinforcement and slope protection in construction. It has the advantages of high strength, corrosion resistance, and easy installation. It can effectively enhance the tensile and shear resistance of the soil and improve the stability of the slope. It is suitable for slope protection projects under various geological conditions. This product adopts advanced manufacturing technology and undergoes strict quality inspection to ensure that its performance indicators are stable and reliable, and is deeply welcomed by construction engineers. Whether it is a highway, railway or construction project, Reinforcement Composite Fiberglass Geogrid for Retaining Wall can play an important supporting role and provide a strong foundation for engineering construction.

Rebar-reinforced composite fiber geogrid is a building material used for retaining wall and slope reinforcement. It is made of high-strength glass fiber mesh and polymer binder, and has good tensile strength, corrosion resistance and weather resistance. This material can be used with granular materials such as soil and stone to form a composite structure, which greatly improves the overall shear strength and tensile strength, thereby enhancing the bearing capacity of retaining walls and slopes. Compared with traditional steel or pile reinforcement structures, this geogrid is lighter and simpler to construct. It also has good water permeability and air permeability, which is conducive to the drainage and ventilation of the soil. In general, this steel-reinforced composite fiber geogrid is a cost-effective and easy-to-construct retaining wall and slope reinforcement material, which has been widely used in engineering practice.

Parameter

ltem | GSB 30-30 | GSB 40-40 | GSB 50-50 | GSB 80-80 | GSB 100-100 | GSB 125-125 | GSB 150-150 | |

Size of mesh (mm) | 12.7*12.7~25.4*25.4 | |||||||

Tensile Strength (kN/m) | Longitudinal | ≥30 | ≥40 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

Transverse | ≥30 | ≥40 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 | |

Elongation Rate (%) | ≤4 | |||||||

Temperature Resistance (°C) | 100~280 | |||||||

Advantages of Reinforcement Composite Fiberglass Geogrid for Retaining Wall

1. Good tensile strength and shear strength

Reinforced composite fiber materials have the characteristics of high strength, which can greatly improve the tensile and shear resistance of the overall structure, thereby enhancing the bearing capacity of retaining walls and slopes.

2. Excellent corrosion resistance and weather resistance

Composite materials are not easily affected by chemical corrosion and natural environmental factors, have strong anti-aging properties and long service life.

3. Lightweight and convenient construction

Compared with traditional reinforcement methods of steel bars or wooden piles, this material is lighter, easier to transport and construct, and greatly reduces the cost of the project.

4. Good water permeability and air permeability

Geogrids have a certain porosity, which is conducive to the drainage and ventilation of the soil and improves the moisture condition of the foundation.

5. Applicable to various geological conditions

This material can be used in combination with different types of granular soil, gravel and other materials, and is suitable for various geological environments.

In general, reinforced composite fiber geogrids are a retaining wall and slope reinforcement material with excellent performance and convenient construction, and are widely favored in actual projects.

Reinforcement Composite Fiberglass Geogrid for Retaining Wall Related Applications

1. Retaining wall reinforcement

This material can be used as a reinforcement layer for retaining walls, greatly improving the tensile strength and shear strength of the wall and improving the overall bearing capacity.

2. Slope support

Laying geogrids on the surface of the slope can enhance the stability of the slope and prevent landslides and collapses.

3. Highway roadbed reinforcement

Laying geogrids under the highway roadbed can enhance the bearing capacity of the roadbed and effectively prevent road subsidence.

4. Railway roadbed reinforcement

The railway roadbed can also be reinforced with geogrids to improve the shear strength and tensile strength of the roadbed.

5. Filler reinforcement

Geogrids can be used in combination with fillers such as crushed stone and gravel to form a composite structure to enhance the overall stability of the filler.

6. Foundation reinforcement

Using geogrids under the foundation of a building can improve the bearing capacity of the foundation and reduce the risk of foundation subsidence.

In short, steel-reinforced composite fiber geogrid is a high-quality reinforcement material widely used in various civil engineering projects, playing an important role in retaining walls, slopes, roadbeds, foundations and other fields.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!