EPDM Geomembrane

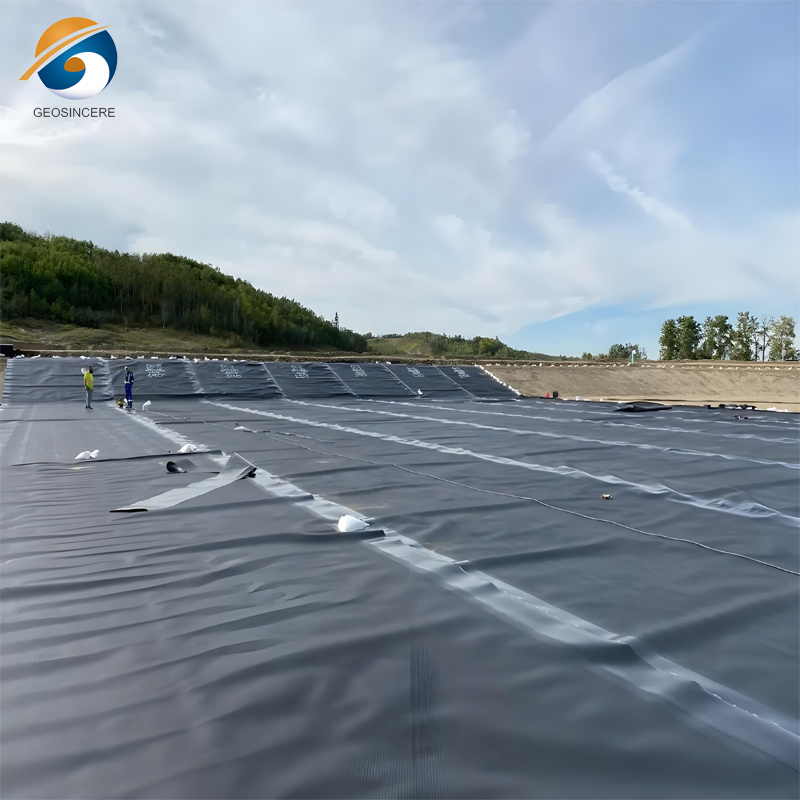

EPDM geomembrane, or ethylene propylene diene monomer geomembrane, is a highly versatile and durable synthetic rubber material widely used in various environmental applications. Known for its exceptional resistance to UV radiation, ozone, and extreme weather conditions, EPDM geomembrane is particularly effective for waterproofing and containment solutions. Its flexibility allows it to conform to various substrate shapes, making it ideal for use in diverse environments such as landfills, ponds, reservoirs, and agricultural applications.

One of the key advantages of EPDM geomembranes is their long service life, often exceeding 30 years with proper installation and maintenance. This longevity is attributed to the material's inherent resistance to degradation from harsh chemicals and environmental factors. Additionally, EPDM geomembranes are available in various thicknesses and widths, providing flexibility in design and application to meet specific project requirements.

EPDM geomembranes offer a reliable and efficient solution for waterproofing and containment needs across multiple industries, combining durability, flexibility, and ease of installation.

EPDM geomembranes are synthetic rubber liners made from ethylene propylene diene monomer, a versatile and durable material known for its excellent resistance to UV radiation, ozone, and extreme temperatures. These geomembranes are widely used in various applications, including landfills, mining, ponds, and water containment systems due to their impermeability and long lifespan. The flexibility of EPDM allows it to conform to irregular surfaces, making installation easier and more efficient. Additionally, EPDM geomembranes exhibit outstanding chemical resistance, making them suitable for environments where exposure to harsh substances is common. Their ability to withstand environmental stressors ensures that they maintain structural integrity over time, reducing the risk of leaks and contamination. Furthermore, these geomembranes can be easily welded and repaired, enhancing their longevity and reliability. Overall, EPDM geomembranes provide a sustainable and effective solution for numerous containment and environmental protection challenges.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

EPDM Geomembrane Features

1. Durability: EPDM geomembranes are highly resistant to physical wear and tear, making them suitable for long-term applications in harsh environments.

2. Chemical Resistance: They exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents, ensuring reliability in industrial applications.

3. UV and Ozone Resistance: EPDM materials are specifically designed to withstand prolonged exposure to ultraviolet (UV) light and ozone, preventing degradation and maintaining performance over time.

4. Temperature Tolerance: These geomembranes can operate effectively across a wide temperature range, from extreme cold to high heat, making them versatile for various climates.

5. Flexibility: The inherent flexibility of EPDM allows it to conform to uneven surfaces, facilitating easier installation and reducing the likelihood of punctures.

6. Seam Integrity: EPDM geomembranes can be easily welded and repaired, ensuring strong seams that maintain impermeability and structural integrity.

7. Waterproofing: With excellent impermeability properties, EPDM geomembranes provide reliable barriers against water and other liquids, making them ideal for containment applications.

8. Lightweight: Their lightweight nature simplifies handling and installation, reducing labor costs and time.

9. Eco-Friendly: EPDM is a sustainable material, often recyclable, contributing to environmentally friendly practices in construction and containment.

10. Cost-Effective: The long lifespan and low maintenance requirements of EPDM geomembranes make them a cost-effective solution for various applications, providing significant savings over time.

Applications of EPDM Geomembrane

1. Landfills: EPDM geomembranes are widely used as liners in landfills to prevent leachate from contaminating groundwater. Their impermeability ensures effective containment of hazardous materials.

2. Mining: In the mining industry, EPDM geomembranes are utilized for heap leach pads and tailings storage facilities, providing a reliable barrier against seepage and environmental contamination.

3. Water Containment: These geomembranes are ideal for ponds, reservoirs, and irrigation canals, ensuring that water stays contained and minimizing evaporation losses.

4. Agricultural Applications: EPDM geomembranes are used in agricultural ponds and fish farms to maintain water quality and prevent leakage, supporting sustainable farming practices.

5. Wastewater Treatment: They are employed in wastewater treatment facilities as liners for anaerobic digesters and holding tanks, providing a durable and chemical-resistant barrier.

6. Dams and Embankments: EPDM geomembranes can be used in the construction of dams and embankments to enhance stability and reduce water seepage through soil layers.

7. Green Roof Systems: In green roofing applications, EPDM geomembranes serve as waterproofing layers, protecting the underlying structure from water damage while allowing plant growth.

8. Recreational Facilities: They are used in the construction of artificial lakes, swimming pools, and water parks, offering a reliable waterproof barrier that enhances user experience.

9. Industrial Applications: EPDM geomembranes are utilized in various industrial processes, including chemical storage tanks and containment areas, ensuring safety and compliance with environmental regulations.

10. Flood Control: These geomembranes can also be deployed in flood control systems, providing temporary barriers to manage water flow and prevent flooding in vulnerable areas.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrana and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembana, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrana research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembrana and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembrana and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembrana and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!