Anti Seepage HDPE Composite Geomembrane for Tailing Bottom

Anti-Seepage HDPE Composite Geomembrane is a high-performance anti-seepage product, which is widely used in mine tailings ponds, reservoirs, artificial lakes, environmental protection projects and other fields, and can effectively block the leakage of water and pollutants. It is composed of HDPE (high-density polyethylene) and composite materials, and has excellent tensile strength, aging resistance, chemical corrosion resistance and other characteristics, and can provide reliable anti-seepage protection for the substrate. The product adopts advanced manufacturing technology in the production process to ensure good flatness and durability. At the same time, the surface also has a certain roughness, which can increase the adhesion with the substrate. In addition, HDPE Composite Geomembrane also has the advantages of light weight, convenient installation, and fast construction speed, which is very suitable for anti-seepage engineering applications in complex environments.

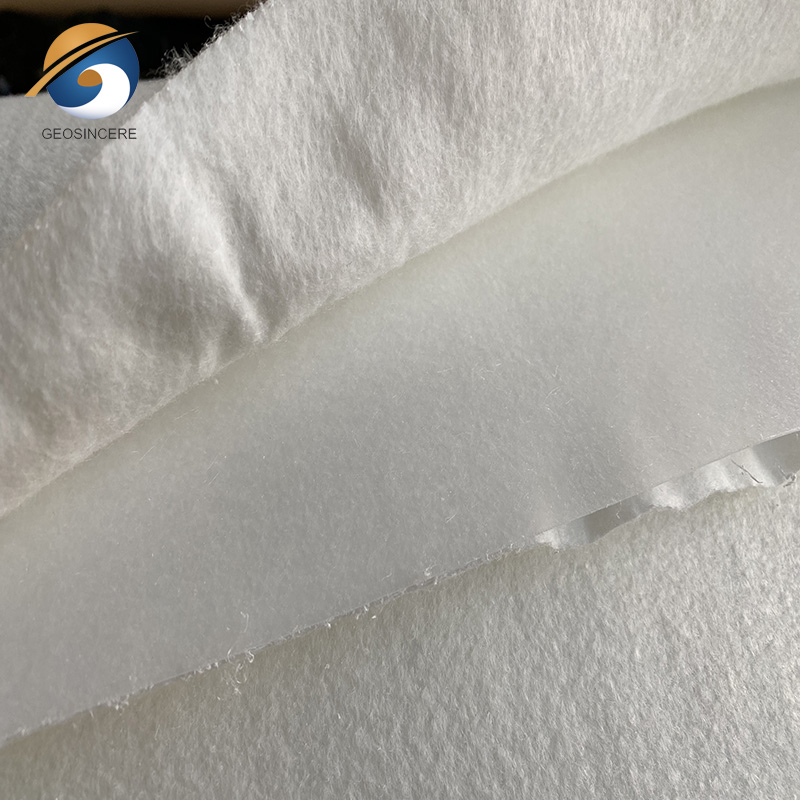

HDPE composite geomembrane is a highly effective solution for tailing bottom seepage control. It features a high-density polyethylene (HDPE) geomembrane layer bonded to a nonwoven geotextile backing, providing a durable and impermeable barrier against the migration of contaminants from tailing ponds or other waste containment facilities. The HDPE layer offers exceptional resistance to chemical and environmental degradation, while the geotextile backing provides strength, puncture resistance, and ease of installation. This composite system is widely used in the mining, waste management, and environmental remediation industries to prevent groundwater pollution and ensure the long-term integrity of tailing containment structures. With its proven performance and versatility, the HDPE composite geomembrane is a reliable choice for effectively managing tailing seepage and safeguarding the surrounding ecosystem.

Parameter

Test ltem | Test Properties | Unit | BCM4 | BCM5 | BCM5 | BCM7 | BCM8 |

Weight | g/㎡ | 400 | 500 | 600 | 700 | 800 | |

Film Thickness | Mm | 0.25-0.35 | 0.30-0.50 | ||||

Mechanical Properties | Break Strength | kN/m | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 |

Break Elongation | % | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 | |

CBR Burst Strength | KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | |

Tear Resistance | KN | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | |

Peel Strength | N/cm | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | |

Hydrostatic Pressure | Film Thickness | Mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 |

One cloth one film | Mpa | 0.4 | 0.5. | 0.6 | 0.8 | 1.0 | |

Two cloth one film | Mpa | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | |

Advantages of Anti Seepage HDPE Composite Geomembrane for Tailing Bottom

1. Excellent anti-seepage performance: HDPE composite membrane has excellent anti-seepage and chemical corrosion resistance, can effectively block the infiltration of tailings leachate and groundwater, and eliminate environmental pollution.

2. Strong tensile strength: The structural design of the composite material makes this anti-seepage membrane have high tensile strength, can withstand large stress and deformation, and can maintain good integrity even in the environment of large deformation of the tailings pond.

3. Excellent anti-aging performance: HDPE materials and special production processes ensure that the composite membrane has excellent weather resistance and anti-aging performance, and its service life can last for decades.

4. Convenient and fast installation: Compared with traditional clay linings, HDPE composite membranes are light in weight, simple and fast in installation, and can greatly shorten the construction period of tailings ponds.

5. Strong adaptability: The product can be customized according to the specific conditions of the tailings pond to meet the needs of different sizes and complex terrains, and has wide adaptability.

6. Economical and practical: Compared with other anti-seepage systems, HDPE composite membranes have a lower comprehensive cost and high cost performance, making them an economical choice for tailings pond construction.

In short, HDPE composite anti-seepage membrane has become the preferred material for anti-leakage at the bottom of tailings ponds due to its excellent technical performance and economy.

Related Applications of Anti Seepage HDPE Composite Geomembrane for Tailing Bottom

1. Anti-seepage layer at the bottom of tailings pond: This is the main application area of this product. HDPE composite membrane can be used as the main anti-seepage layer at the bottom of tailings pond, effectively blocking the infiltration of tailings leachate into groundwater and soil, and avoiding serious environmental pollution.

2. Tailings dam lining: HDPE composite membrane is also widely used in the lining of tailings dam, providing reliable anti-seepage protection for the dam body and enhancing the overall stability of the dam body.

3. Tailings pond cover: During the closure of the tailings pond, HDPE composite membrane can also be used as a covering layer to block rainwater infiltration and ultimately achieve ecological restoration of the tailings pond.

4. Leachate collection system: HDPE composite membrane can be laid at the bottom of the leachate collection ditch or pool to ensure that the leachate can be fully collected and properly treated.

5. Other environmental protection projects: In addition to tailings ponds, HDPE composite membranes are also widely used in the anti-seepage layer of various environmental protection projects such as landfills, artificial lakes/reservoirs, and leachate treatment stations.

In general, with its excellent anti-seepage performance and adaptability, HDPE composite membrane has become one of the preferred materials in the field of anti-seepage of tailings ponds and various environmental protection projects. With the continuous improvement of environmental awareness, this anti-seepage membrane will surely have a wider application prospect in the future.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrane and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembanes, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications.

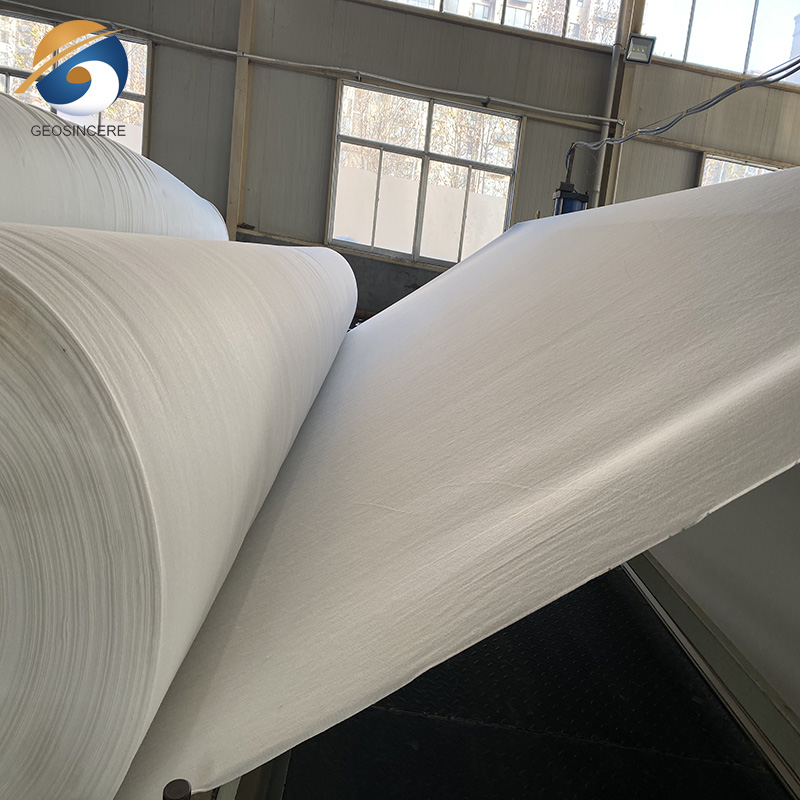

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembranes and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!