Why Choose Geomembrane as the Anti-Seepage Material?

In the fields of modern engineering and environmental protection, the selection of anti-seepage materials plays a crucial role in protecting our water resources and ensuring the integrity of various structures. Among the many available options, geomembranes are an excellent solution that offers a unique combination of efficiency, durability, and versatility. As industry faces increasingly severe challenges related to water management and soil pollution, choosing geomembranes as anti-seepage materials can not only improve project efficiency, but also support responsible resource management and ecological protection.

Whether in landfills, reservoirs, or mining operations, the advantages of geomembranes as anti-seepage materials are remarkable, with the potential to improve performance and long-term reliability in constantly changing landscapes.

1. How Superior Is the Anti-Seepage Performance of Geomembrane?

The anti-seepage performance of geomembranes is widely recognized for its effectiveness in preventing the migration of liquids and contaminants through soil and other materials. Several factors contribute to this superiority:

1.1 Impermeability: Geomembranes are designed to provide a nearly impermeable barrier, with very low permeability coefficients. This means they can effectively prevent water and other liquids from seeping through, making them ideal for applications like landfills and containment ponds.

1.2 Material Composition: Most geomembranes are made from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), which are inherently resistant to chemical degradation and environmental factors. This chemical resistance further enhances their ability to maintain a waterproof barrier.

1.3 Durability: Geomembranes are engineered to withstand harsh environmental conditions, including UV radiation, temperature fluctuations, and mechanical stress. Their durability ensures that the anti-seepage properties remain intact over time, even in challenging settings.

1.4 Seam Integrity: Advanced installation techniques and welding methods ensure that seams between geomembrane panels are strong and watertight. Proper seam integrity is crucial for maintaining the overall anti-seepage performance of the system.

1.5 Flexibility: Geomembranes can conform to irregular surfaces and shapes, creating a tight seal that minimizes the risk of gaps or leaks. This flexibility allows for effective installation in various applications, ensuring comprehensive coverage.

2. What Are The Characteristics of Geomembranes?

2.1 Impermeability: Geomembranes are designed to be highly impermeable, preventing the passage of liquids and gases.

2.2 Durability: They are resistant to puncturing, tearing, and UV radiation, making them suitable for long-term use in various environmental conditions.

2.3 Flexibility: Many geomembranes are flexible, allowing them to conform to the underlying surface and accommodate movement or settlement.

2.4 Chemical Resistance: They can withstand exposure to a wide range of chemicals, making them suitable for containment applications in landfills, wastewater treatment, and chemical storage.

2.5 Temperature Resistance: Geomembranes can perform well across a wide temperature range, which is important for applications in various climates.

2.6 Lightweight: They are typically lighter than traditional materials, which can reduce transportation and installation costs.

2.7 Ease of Installation: Geomembranes can often be installed quickly and efficiently, sometimes using techniques like welding to create seamless barriers.

2.8 Environmental Compatibility: Many geomembranes are designed to be environmentally friendly and can be recycled or reused.

2.9 Cost-Effectiveness: They provide a cost-effective solution for containment and barrier applications compared to traditional materials.

2.10 Versatility: Geomembranes can be used in various applications, including landfill liners, pond liners, and containment systems for hazardous materials.

3. What Application Areas are Geomembranes Suitable for?

3.1 Landfill Liners: Used to prevent leachate from contaminating groundwater in municipal and industrial landfills.

3.2 Containment Ponds: Employed in mining and industrial operations to contain wastewater, tailings, or other hazardous materials.

3.3 Agricultural Applications: Utilized in irrigation canals, ponds, and reservoirs to reduce water loss through seepage.

3.4 Wastewater Treatment: Applied in lagoons and treatment ponds to prevent contamination of surrounding soil and groundwater.

3.5 Environmental Remediation: Used in capping and containment systems to manage contaminated sites and prevent further pollution.

3.6 Green Roofs and Landscape Applications: Serve as barriers to protect the underlying structure from moisture and root penetration.

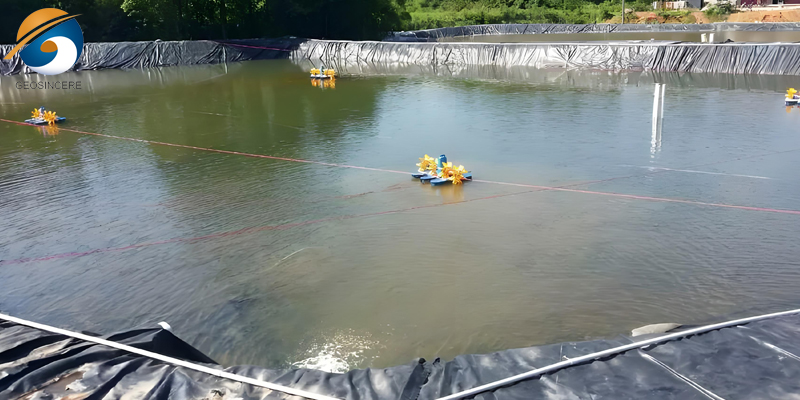

3.7 Aquaculture: Used in fish farming and aquaculture systems to create ponds that retain water and prevent contamination.

3.8 Infrastructure Projects: Employed in road and railway construction to manage groundwater and prevent erosion.

3.9 Dams and Reservoirs: Used as liners to enhance the impermeability of dam structures and water storage facilities.

3.10 Solar Farms: Applied in the construction of solar energy facilities to manage drainage and prevent contamination.

4. Summary

Geomembranes are an ideal choice for anti-seepage materials due to their exceptional impermeability, durability, and flexibility. Their ability to effectively prevent the passage of liquids makes them highly suitable for applications such as landfill liners and containment ponds. Additionally, geomembranes are resistant to puncturing, tearing, and chemical exposure, ensuring long-term performance in various environmental conditions. Overall, geomembranes provide a cost-effective and reliable solution for controlling seepage and protecting groundwater resources.

If you have any questions or needs, please feel free to contact us at any time.