What’s So Wonderful About Geomembrane Waterproofing Applications?

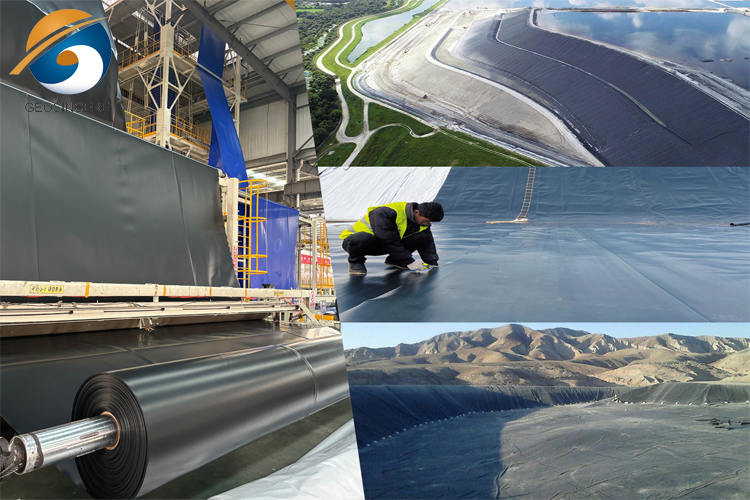

Imagine a virtually indestructible waterproofing solution that protects your project from the most persistent liquid intrusions. Made from durable materials like high-density polyethylene (HDPE) and polyvinyl chloride (PVC), geomembranes are used in everything from landfill pond liners and reservoir barriers to dam reinforcement and tunnel waterproofing. They stand the test of time no matter what the elements throw at them.

So what’s so amazing about geomembrane waterproofing applications? What are the real key benefits? Let’s explore!

1. What Are The Common Types of Geomembranes Used in Waterproofing Applications?

When it comes to geomembrane waterproofing applications, there are several common types that are widely used due to their unique properties and performance advantages.

1.1 High-density polyethylene (HDPE) geomembranes:

- Known for their excellent durability, chemical resistance and long-term stability

- Commonly used in landfill liners, pond/reservoir waterproofing and environmental remediation projects

- Provides excellent long-term performance and withstands harsh conditions

1.2 Polyvinyl chloride (PVC) geomembranes:

- Provides excellent flexibility, flexibility and easy installation

- Widely used in a variety of applications including roofs, tunnels and water containment structures

- Provides reliable waterproofing and protection against environmental degradation

1.3 Bentonite composite geomembranes:

- Combines the strength of synthetic geomembranes with the natural sealing properties of bentonite

- Ideal for applications requiring a self-healing, low-permeability barrier, such as landfill liners and pond/reservoir waterproofing

1.4 Polypropylene (PP) geomembranes:

- Has excellent tensile strength, puncture resistance and UV resistance

- Commonly used in demanding applications such as secondary containment systems, landfills, wastewater treatment ponds and mining operations

- Delivering reliable, long-term performance in challenging environments

1.5 Ethylene Propylene Diene Monomer (EPDM) Geomembranes:

- Known for their excellent flexibility and resistance to weathering and UV rays

- Commonly used for roofing, pond/reservoir liners and other outdoor waterproofing applications

- Provides a durable, reliable waterproof barrier

Each geomembrane type has its own unique advantages, and the choice will depend on specific project requirements, environmental conditions and performance needs. Understanding the characteristics of these different options is critical to selecting the right geomembrane for any waterproofing application.

2. What Specific Environmental Projects Benefit from Geomembrane Waterproofing?

2.1 Landfill Liners and Covers:

- HDPE and bentonite composite geomembranes are widely used to line the bottom and sides of landfills

- Create an impermeable barrier to prevent leakage of hazardous leachate into the surrounding soil and groundwater

- Control the release of methane and other gases in landfill cover systems.

2.2 Wastewater Treatment Ponds:

- Geomembranes are essential for lining the bottom and sides of wastewater treatment ponds to prevent pollutants from seeping into the soil and groundwater.

- Especially important for industrial facilities, agricultural operations, and municipal wastewater treatment plants.

2.3 Mining and Tailings Pond Containment:

- In mining operations, geomembranes are used to line and contain the remaining materials (tailings) from the mining process

- This prevents heavy metals, chemicals, and other pollutants from leaking into the surrounding environment

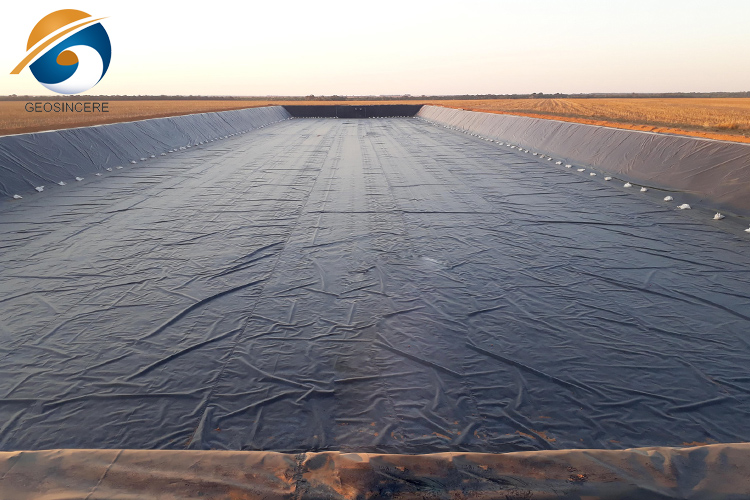

2.4 Reservoir and Pond Lining:

- Widely used to line reservoirs, ponds, and other water storage facilities, ensuring the long-term integrity of water bodies and preventing seepage or contamination.

- Helps prevent water loss from seepage and maintain the integrity of these important water resources

2.5 Wetland and Habitat Restoration:

- Geomembranes can be used to create artificial wetlands, ponds, and other aquatic habitats for ecological restoration projects.

- By providing a reliable waterproof barrier, these materials help successfully restore and protect sensitive ecosystems

2.6 Stormwater Management:

- Can be used to construct stormwater detention ponds and storage tanks, helping to control runoff and prevent the spread of pollutants into nearby waterways.

2.7 Groundwater Remediation:

- Geomembranes can be used in groundwater remediation projects, they help contain and isolate contaminated areas, preventing the spread of pollutants

By adopting geomembrane waterproofing solutions, these environmental projects can improve their overall performance, sustainability, and long-term protection of valuable natural resources and ecosystems.

3. How Do Geomembranes Compare to Traditional Waterproofing Methods in Terms of Cost?

3.1 Initial Cost:

- Compared to some traditional waterproofing materials, such as asphalt or bitumen coatings, geomembranes generally have a higher upfront cost.

- However, the advanced manufacturing processes and specialized materials used in geomembranes make their initial price higher.

3.2 Durability and Service Life:

- Geomembranes are known for their superior durability and long-lasting performance, often lasting for decades.

- This extended service life can result in significant cost savings over the life of a project compared to traditional waterproofing methods, as it reduces the need for frequent replacement or repairs.

3.3 Installation Efficiency:

- Geomembranes generally require fewer specialized tools and techniques for installation, which can reduce labor costs compared to some traditional waterproofing systems.

- Geomembranes are easy to handle and deploy, reducing installation time and further saving costs. The ease and speed of their installation can offset these higher initial expenses.

3.4 Maintenance and Repair Costs:

- Geomembranes are highly resistant to weathering, chemicals, and other environmental factors that can degrade the performance of traditional waterproofing materials over time.

- In the event of a rupture or damage, geomembranes can often be patched or repaired, whereas other waterproofing methods may require more extensive and expensive remediation.

3.5 Environmental and Energy Efficiency:

- Geomembranes play a vital role in environmental protection, helping to prevent soil and groundwater contamination.

- Geomembranes can save costs by improving a project’s energy efficiency.

While the initial cost of a geomembrane may be higher, its superior performance, durability, and efficiency can make it a more cost-effective solution in the long run, especially for large-scale or high-risk waterproofing applications. The combined benefits of a geomembrane can often offset the higher upfront investment, making it a smart choice for many construction and environmental projects.

4. How Is The Geomembrane Installed in The Wastewater Treatment Tank?

4.1 Foundation preparation:

- Level and compact the bottom and slope of the tank to ensure that the surface is flat and free of sharp objects or protrusions.

- Lay a sand cushion or gravel cushion on the bottom of the tank to ensure the stability and flatness of the foundation.

4.2 Geomembrane installation:

- Unfold the selected geomembrane (such as HDPE or LLDPE membrane) to ensure that there are no wrinkles and folds.

- Lay the membrane to the bottom and slope of the tank according to the designed size and make appropriate overlapping connections.

- Use hot melt welding or bonding to firmly connect each piece of geomembrane to ensure overall impermeability.

4.3 Protection layer installation:

- In order to protect the geomembrane from damage, a protective layer, such as a sand and gravel layer or other protective materials, is usually laid on it.

- The thickness and material of the protective layer depend on the specific situation and need to be able to withstand the pressure and load during the operation of the tank.

4.4 Edge fixing:

- Fix the geomembrane firmly at the edge of the pool, commonly used methods include burial depth or reinforced concrete anchoring.

- Ensure that the edge is fixed reliably to prevent the geomembrane from falling off or slipping.

4.5 Quality inspection:

- During the installation process and after completion, carefully check the connection and integrity of the geomembrane.

- Carry out permeability tests when necessary to ensure that the anti-seepage performance required by the design is achieved.

The entire installation process requires a professional construction team and strict quality control to ensure that the geomembrane plays a good isolation and anti-seepage role in the wastewater treatment pool.

5. Summarize

Geomembranes are designed to be environmentally friendly, providing strong protection while minimizing impact on surrounding ecosystems. This makes them a smart choice for sustainable infrastructure and environmental protection projects.

GEOSINCERE Geomembranes have strong technology, innovative engineering solutions and customized services to meet your needs.