What Should Know About the Comprehensive Guide to Geomembrana 1.5mm for Mining?

Geomembranes have become an integral component in the mining industry, playing a crucial role in the safe and responsible management of various mining activities. Specifically, 1.5mm geomembranes have emerged as a preferred choice for a wide range of mining-related projects, offering unparalleled performance and environmental protection.

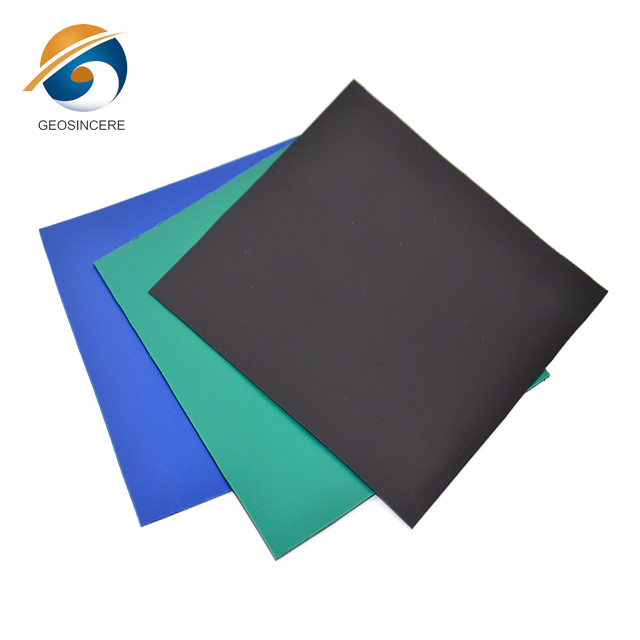

GEOSINCERE Geomembrane, a leading manufacturer and supplier of high-quality geosynthetic solutions, provides valuable insights into the comprehensive guide to using 1.5mm geomembrana in the mining sector. Products can be customized in terms of size and thickness, ensuring a perfect fit for the unique requirements of each project.

Read the following article to learn more about Geomembrana 1.5mm for Mining projects.

1. What Is Geomembrana 1.5mm?

Geomembrana 1.5mm refers to a specialized type of geosynthetic material that is 1.5 millimeters (mm) in thickness. Geomembranes are a category of synthetic, impermeable barriers that are primarily used in various engineering and environmental applications to prevent the migration of liquids, gases, or other materials. The 1.5mm thickness of this particular geomembrane makes it a popular choice for use in the mining industry, as it provides enhanced durability, strength, and impermeability compared to thinner alternatives.

The increased thickness of the 1.5mm geomembrane allows it to be more resistant to punctures, tears, and other types of physical damage that can occur in the demanding environments found in mining operations. This added thickness also gives the material greater tensile strength, enabling it to withstand the heavy loads and stresses associated with the placement of equipment, the movement of materials, and other mining activities. Additionally, the 1.5mm thickness enhances the geomembrane's ability to create an effective, low-permeability barrier, significantly reducing the risk of leakage or the migration of contaminants into the surrounding environment. This versatility makes the 1.5mm geomembrane a valuable solution for a wide range of mining applications, such as tailings ponds, heap leach pads, and landfill liners.

2. What Are Mining Pond?

Mining ponds are large, engineered water bodies that are a critical component of many mining operations. These ponds serve a variety of essential functions in the mining industry, including the storage and containment of mining waste materials, the management of process water, and the treatment of wastewater.

Tailings ponds are a common type of mining pond, used to store the finely ground rock and mineral particles (known as tailings) that remain after the valuable minerals have been extracted from the ore. These ponds are designed to safely contain the potentially harmful tailings and prevent them from contaminating the surrounding environment.

Other types of mining ponds may be used for the storage of process water, which is used in various stages of mineral extraction and processing. These ponds help to manage water resources and ensure that water is recycled and reused within the mining operation, reducing the industry's overall water consumption and environmental impact.

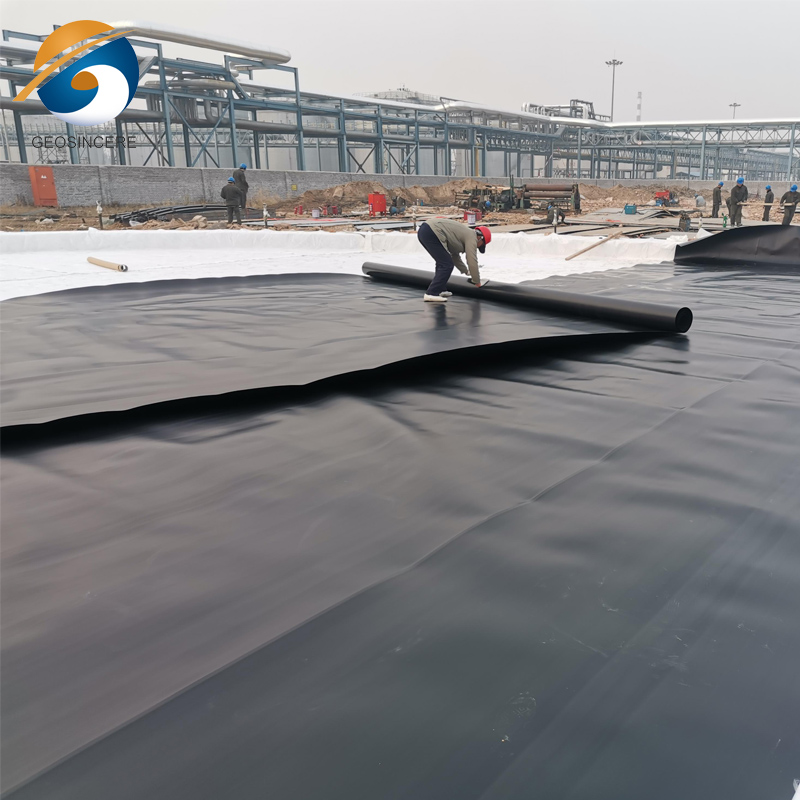

Mining ponds require careful engineering and design to ensure their structural integrity, as well as the implementation of comprehensive environmental safeguards and monitoring systems. Geomembranes, such as the 1.5mm geomembrana, play a crucial role in the lining and containment of these ponds, providing a reliable and long-lasting barrier to prevent the leakage of contaminants into the surrounding soil and groundwater.

3. What Are The Advantages of Geomembrana 1.5mm for Mining?

1. Durability: The 1.5mm thickness of the geomembrane makes it highly resistant to punctures, tears, and other types of physical damage that can occur in the challenging mining environment. This enhanced durability ensures the long-term integrity and performance of the material.

2. Strength: The increased thickness of the 1.5mm geomembrana provides greater tensile strength, allowing it to withstand the heavy loads and stresses associated with mining operations, such as the placement of equipment and the movement of heavy materials.

3. Impermeability: The 1.5mm thickness significantly improves the geomembrane's ability to create an effective, low-permeability barrier, reducing the risk of leakage or the migration of contaminants into the surrounding soil and groundwater.

4. Versatility: The 1.5mm geomembrana can be used in a wide range of mining applications, including the lining of tailings ponds, heap leach pads, landfills, and other critical infrastructure. This versatility makes it a valuable solution for the mining industry.

5. Environmental Protection: By providing a reliable and long-lasting barrier, the 1.5mm geomembrana helps to prevent the release of harmful substances into the environment, supporting the mining industry's efforts to operate in a more sustainable and responsible manner.

6. Cost-effectiveness: Durable performance can lead to lower long-term maintenance and replacement costs.

Overall, the combination of durability, strength, impermeability, and versatility make the 1.5mm geomembrana a highly valuable and widely-adopted solution for a variety of mining applications, contributing to the safe and responsible management of mining activities.

4. How To Choose Right Geomembrana 1.5mm for Mining?

Material Composition:

- HDPE (high-density polyethylene) is a commonly recommended material for mining geomembranes due to its excellent chemical stability, resistance to permeability, and corrosion resistance.

Thickness:

- For the primary bottom liner system, geomembrane thickness typically ranges from 1.0mm to 2.0mm to ensure sufficient durability against the significant waste and leachate pressures encountered in mining.

- Sidewall liners may use a thinner 0.5mm to 1.5mm geomembrane, as they experience less mechanical stress.

- The specific thickness selected should consider factors like groundwater levels and the expected operational lifespan of the mining facility.

Installation:

- Proper installation is crucial, involving surface preparation, precise deployment of the bottom and side liners, specialized welding/seaming techniques, and comprehensive inspection.

- Strict adherence to installation specifications is essential to ensure the geomembrane's long-term integrity and ability to effectively prevent leakage.

Compatibility:

- Assess the geomembrane's compatibility with other mining infrastructure components, such as geotextiles, geocomposites, and drainage systems.

- Ensuring compatibility helps create a reliable and well-integrated containment solution.

Supplier Selection:

- Choose a reputable geomembrane manufacturer and supplier, such as GEOSINCERE Geomembrane, that can provide high-quality, certified products at competitive prices.

- The supplier's expertise and support in product selection, installation guidance, and ongoing maintenance is vital for the long-term performance of the mining geomembrane.

By carefully considering these key factors, mining operators can select the most appropriate 1.5mm geomembrana that will deliver the necessary durability, impermeability, and environmental protection for their specific mining applications.

5. Summary

The use of 1.5mm geomembranes in mining operations has become a widely adopted practice, providing a practical and effective solution for a range of containment, lining, and environmental protection needs within the industry.The 1.5mm thickness is a popular choice for many mining applications due to its balance of strength, durability, and flexibility.By preventing the leakage of contaminants, they help safeguard the surrounding ecosystems and groundwater resources, contributing to the industry's ongoing efforts to minimize the environmental impact of mining activities.Geomembranes have become an essential component in mining operations, providing a reliable and cost-effective solution for containment, lining, and environmental protection.