What Is HDPE Waterproofing Membrane?

In the ever-evolving world of construction, HDPE waterproofing membrane has emerged as a groundbreaking solution to combat water intrusion. With its exceptional properties and diverse applications, this synthetic material is revolutionizing the industry, ensuring the longevity and durability of structures. High-Density Polyethylene (HDPE) stands at the core of this waterproofing membrane, providing a resilient and versatile thermoplastic polymer that effectively prevents water penetration into roofs, basements, and foundations.

As the professional geomembrane manufacturer and supplier, The BPM factory holds certifications such as ISO9001, ISO14001, and OHSAS18001, and geomembranes have received approvals from TUV, Soncap, SASO, BV, SGS, Intertek, and other esteemed organizations.BPM offers geomembrane liners with different types and thickness for various applications at best factory price.

Reading this article will take you to a deeper understanding of HDPE Waterproofing Membrane.

1. What Is HDPE Waterproofing Membrane?

HDPE waterproofing membrane is a synthetic material used in construction to prevent the penetration of water into structures such as roofs, basements, and foundations. HDPE stands for High-Density Polyethylene, which is a durable and versatile thermoplastic polymer. This waterproofing membrane is specifically designed to create a barrier that effectively resists water infiltration, protecting buildings from moisture-related damage. With its exceptional properties, including durability, flexibility, and resistance to chemicals, UV radiation, and root penetration, HDPE membrane offers long-lasting and reliable waterproofing solutions. It extends the lifespan of structures by preventing water damage and maintaining their structural integrity.

2. What Are The Performance and Benefits of HDPE Waterproofing Membrane?

HDPE waterproofing membrane boasts a range of properties and benefits that make it a top choice for protecting structures from water intrusion and extending their lifespan. Here are some key characteristics to highlight:

2.1 Durability: Constructed from high-density polyethylene, it exhibits robustness and strength to withstand the rigors of construction environments. It can resist punctures, tears, and abrasions, ensuring long-lasting protection against water infiltration.

2.2 Flexibility: The flexibility of HDPE membrane allows it to adapt to structural movement without compromising its integrity. It can accommodate expansions, contractions, and settlement of the building, maintaining a continuous barrier against water ingress.

2.3 Chemical Resistance: HDPE waterproofing membrane demonstrates excellent resistance to various chemicals, including acids, alkalis, and solvents. This property is particularly valuable in environments where the structure may come into contact with corrosive substances.

2.4 UV Radiation Resistance: HDPE waterproofing membrane is specifically formulated to withstand UV radiation. It does not deteriorate or become brittle under prolonged sun exposure, ensuring reliable performance and longevity, even in outdoor applications.

2.5 Water Intrusion Protection: Its impermeable nature creates a reliable barrier that effectively keeps water out, protecting the building from moisture-related issues such as mold, rot, and structural damage. By providing a watertight seal, the membrane ensures the longevity and durability of the structure.

2.6 Extended Lifespan: By effectively guarding against water intrusion, HDPE membrane significantly extends the lifespan of structures. It prevents water-related deterioration, including corrosion, weakening of materials, and degradation of structural components.

2.7 Versatility: HDPE waterproofing membrane is versatile and suitable for a wide range of applications. Its adaptability to different environments and structures makes it a versatile choice for diverse construction needs.

3.What Are The Applications of HDPE Waterproofing Membrane?

3.1 Roofing systems: HDPE membrane provides reliable waterproofing for flat roofs, pitched roofs, and green roofs, preventing leaks and water damage.

3.2 Basements and foundations: It protects below-grade areas from water seepage, ensuring dry and structurally sound spaces.

3.3 Tunnels and underground structures: HDPE membrane safeguards critical infrastructure components such as tunnels and subways by preventing water infiltration.

3.4 Swimming pools and water features: It creates a watertight seal, preventing water leakage and maintaining the integrity of pools and water features.

3.5 Planters and green roofs: HDPE membrane acts as a protective barrier for planters and green roofs, preserving the underlying structure and supporting healthy vegetation growth.

3.6 Retaining walls: It prevents water seepage, enhancing the stability and longevity of retaining walls.

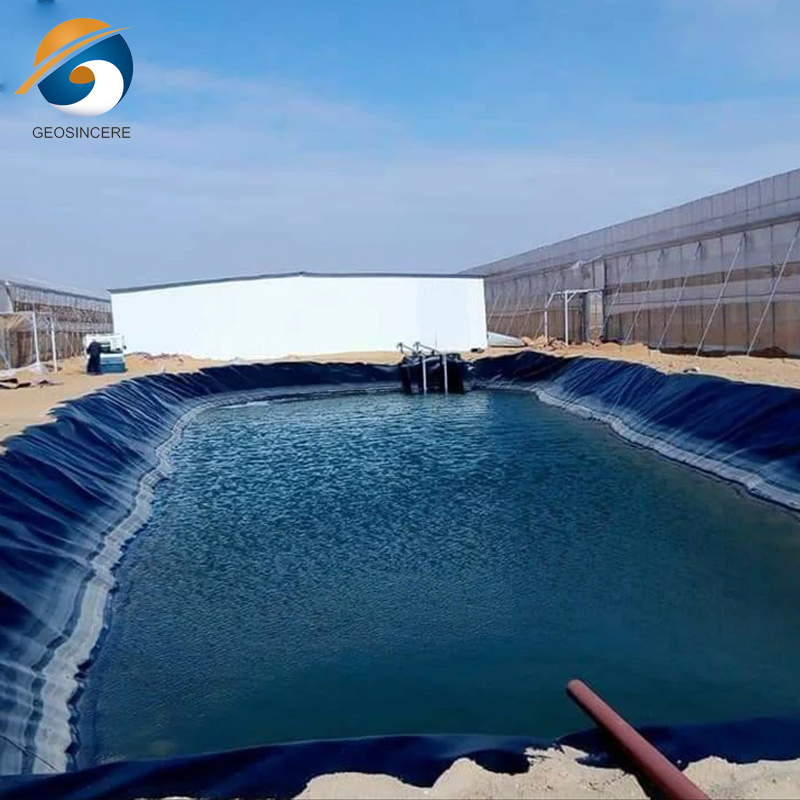

3.7 Pond liners: HDPE membrane serves as a durable and impermeable lining for ponds and reservoirs, ensuring efficient water containment.

These are just a few examples of the diverse applications of HDPE waterproofing membrane. Its versatility, durability, and excellent waterproofing properties make it a preferred choice in various construction projects where effective water barrier solutions are required.

4.Environmental Considerations of HDPE Waterproofing Membrane

HDPE waterproofing membrane not only offers excellent performance but also prioritizes environmental sustainability. Here are key points to address its environmental aspects:

4.1 Recyclability: HDPE membrane is highly recyclable, meaning it can be processed and reused to create new products. This feature reduces waste and promotes a circular economy, minimizing the environmental impact associated with disposal.

4.2 Low Environmental Impact: Compared to other waterproofing materials, HDPE membrane has a relatively low environmental footprint. Its production process consumes less energy and generates fewer greenhouse gas emissions, contributing to a reduced carbon footprint.

4.3 Reduction of Construction Waste: By effectively protecting structures from water damage, HDPE membrane contributes to the reduction of construction waste. It helps prevent the need for costly repairs or replacement of damaged materials, thereby minimizing the overall environmental impact associated with construction projects.

By highlighting the recyclability, low environmental impact, compliance with standards/certifications, and reduction of construction waste, it is evident that HDPE waterproofing membrane is an environmentally responsible choice for waterproofing applications. It aligns with sustainable building practices and contributes towards reducing the environmental footprint of construction projects.

5. Conclusion

HDPE waterproofing membrane has emerged as a key player in the construction industry, offering a superior solution to combat water penetration. Its remarkable properties, diverse applications, and eco-friendliness make it an indispensable tool for ensuring the longevity and integrity of structures. As the industry continues to evolve, HDPE membrane remains at the forefront of innovation, contributing to the sustainable and resilient development of our built environment.