What Is Geomembrane and What Are Its Main Functions?

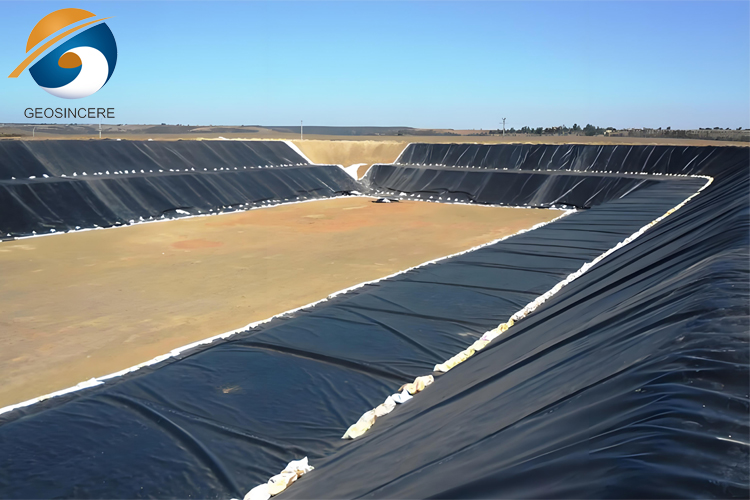

Geomembrane is a key component in modern engineering and environmental management, serving as a synthetic barrier for controlling fluid motion. Its design can withstand harsh conditions, making it an ideal choice for various applications, including landfills, mining, and waterproofing. With the increasing demand for effective environmental protection and resource management, their use has become increasingly important. Understanding the main functions of geomembranes, such as providing impermeability, chemical resistance, and durability, reveals their important role in preventing pollution and ensuring structural integrity. In the following section, we will explore these functions in detail and discuss the different applications of geomembranes in different industries.

1. What Is Geomembrane and What Are Its Main Functions?

Geomembrane is a type of synthetic membrane used primarily as a barrier in civil engineering and environmental applications. Typically made from materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), or polypropylene, geomembranes are designed to prevent the movement of fluids, making them essential in various sectors.

Main Functions of Geomembranes:

- Impermeability: The primary function of geomembranes is to provide a waterproof barrier. This impermeability is crucial in applications such as landfills and reservoirs, where it prevents leachate or water from contaminating the surrounding soil and groundwater.

- Chemical Resistance: Geomembranes are engineered to withstand a wide range of chemicals, making them suitable for applications in mining, chemical storage, and wastewater treatment. This resistance helps protect the environment from hazardous substances.

- Durability and Longevity: Designed to endure harsh environmental conditions, geomembranes are resistant to UV radiation, temperature fluctuations, and biological degradation. This durability ensures their effectiveness over long periods, reducing the need for frequent replacements.

- Stability: In applications involving soil or sediment control, geomembranes help stabilize slopes and prevent erosion. They can be used to reinforce embankments and support the integrity of various structures.

- Cost-Effectiveness: By minimizing leakage and contamination, geomembranes can lead to significant cost savings in environmental remediation and resource management efforts.

2. What Are the Different Application Areas of Geomembranes?

2.1 Landfill Site: Geomembranes are used to prevent leachate leakage and protect groundwater from pollution, and are a key component of landfill site design.

2.2 Water Conservancy Engineering: In reservoirs, reservoirs, and irrigation systems, geomembranes provide waterproof barriers to prevent water loss and ensure the effective utilization of water resources.

2.3 Sewage treatment: Geomembranes are used in sewage treatment facilities to prevent seepage, prevent pollution of soil and groundwater by sewage, and improve treatment efficiency.

2.4 Mining: In mining and tailings management, geomembranes are used to control water flow and prevent chemical leakage, protecting environmental safety.

2.5 Road and Bridge Construction: Geomembranes can be used for isolation and reinforcement of road foundations, improving structural stability and durability, especially on soft soil foundations.

2.6 Ecological Restoration: In ecological restoration projects, geomembranes help control soil erosion and plant growth, while preventing the spread of pollutants.

2.7 Agriculture: In farmland and livestock farms, geomembranes can be used for soil and water conservation and seepage prevention, helping to effectively manage water resources.

2.8 Flood Control and Anti slip: In slope protection and flood control engineering, geomembranes provide additional stability, reducing the risk of soil landslides and erosion.

3. How to Ensure the Effective Installation of Geomembrane?

3.1 Site preparation: Before installation, ensure that the construction site is cleaned up, removing sharp objects, stones, and weeds to avoid damage to the geomembrane during the laying process.

3.2 Material selection: Select appropriate specifications and thicknesses of geomembranes to ensure they meet project requirements. Check the quality and production date of the materials to ensure there are no defects.

3.3 Temperature and weather conditions: Install under suitable weather conditions and avoid construction in extreme temperatures or strong winds to reduce the risk of material deformation and damage.

3.4 Laying method: Lay the geomembrane correctly according to the design requirements, ensuring that the overlapping parts between the membranes meet the specifications. The overlapping width should usually be between 15-30 centimeters to ensure effective anti-seepage effect.

3.5 Welding and Connection: At the places where welding or connection is required, use appropriate welding equipment and techniques to ensure the sealing of the connection. Welding should be uniform and seamless to avoid leakage.

3.6 Testing and Quality Control: During the installation process, regularly inspect the laying of the geomembrane to ensure that there are no wrinkles, bubbles, or other defects. After installation, a water tightness test can be conducted to verify its effectiveness.

3.7 Protective measures: After the installation of the geomembrane is completed, necessary protective measures should be taken to avoid damage caused by subsequent construction, such as covering the soil or other protective materials.

4. Summary

Geomembranes are used as barriers to control fluid movement in various applications, such as landfills, mining, and reservoirs. Intended to provide impermeability to prevent leakage and pollution of the surrounding environment. Its main functions include serving as a protective layer against liquid infiltration, as a containment system for hazardous substances, and promoting the management of rainwater runoff. In addition, they contribute to the stability and lifespan of civil engineering structures by providing necessary support and drainage.

If you have any questions, please feel free to contact us at any time.