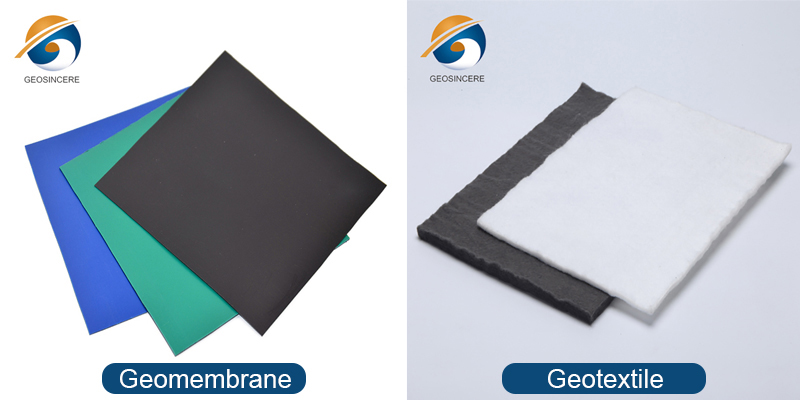

What Is The Difference of Geotextile vs Geomembrane?

Geotextile and geomembrane are both materials used in geotechnical engineering and environmental applications, but they serve different purposes and have distinct characteristics. Let's explore their differences!

1.What is Geomembrane?

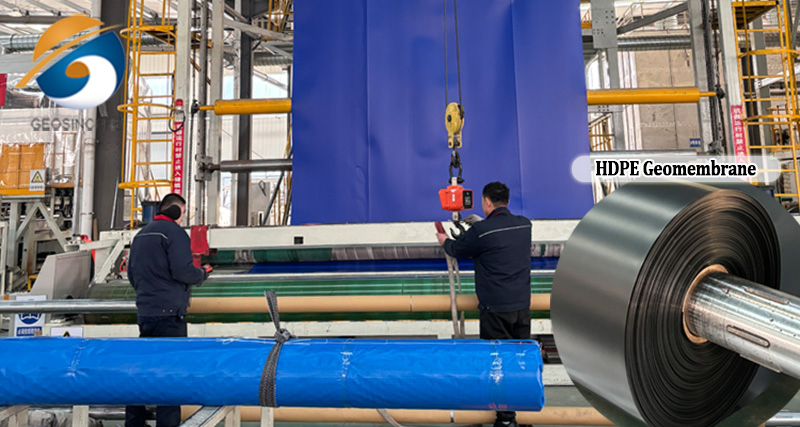

Geomembranet is a thin and flexible sheet made of synthetic polymers, typically high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM).It is a synthetic membrane material used in various engineering and environmental applications to control the movement and containment of fluids or gases.

Geomembranes are designed to have excellent resistance to chemicals, UV radiation, and mechanical stress. They are used to control the movement of fluids, gases, and contaminants in different applications. Geomembranes are designed to be impermeable, meaning they have a low permeability to prevent the passage of liquids or gases. Geomembranes are commonly used in the construction of lining systems for landfills, hazardous waste containment facilities, and industrial storage ponds. They serve as a barrier to prevent the leakage and migration of contaminants into the surrounding environment.

2.What is Geotextile?

Geotextiles are typically made from polypropylene, polyester, or polyethylene fibers. These fibers are woven or non-woven to form a fabric with specific properties. Is a synthetic or natural textile material used in civil engineering and construction applications. It is designed to perform functions related to soil stabilization, filtration, drainage, separation, and erosion control.

Geotextiles can be used to reinforce the soil and prevent erosion. They are often placed beneath roads, embankments, and retaining walls to improve the stability of the soil and distribute loads.They are used in drainage systems, such as subsurface drains and French drains, to prevent clogging and maintain the flow of water. They are commonly used in areas where excess water needs to be removed, such as behind retaining walls, in sports fields, and under roadways.Also can be used to control soil erosion by stabilizing slopes, riverbanks, and shorelines. They help to reduce the impact of water flow and prevent the loss of soil particles.

Geotextiles offer several advantages such as high tensile strength, durability, resistance to biological degradation, and compatibility with various soil types. They are versatile materials that provide cost-effective solutions in a wide range of civil engineering and environmental applications.

OK! Let's have a more intuitive understanding of the main differences between geotextiles and geomembranes through the following comparison table:

Aspect | Geotextile | Geomembrane |

Material | Typically made from woven or non-woven synthetic fibers, such as polypropylene or polyester. | Impermeable syntheticmaterial,such as HDPE, PVC,LDPE,LLDPE or EPDM. |

Function | Filtration,separation,protection.drainage and erosion control | Designed to provide an impermeable barrier for seepage control and environmental protection. |

Permeability | permeable and allow for the passage of water and gases | Impermeable and prevent the passage of water and gases. |

Strength | Tensile strength and resistance to tearing.

| Higher tensile strength.puncture resistance withstand environmental stressors |

Applications | Commonly used in civil engineering, road construction, landscaping, and erosion control projects. They are also used as protective layers for geomembranes. | Widely used in environmental containment applications, such as landfill liners, pond liners, and water storage reservoirs. Also used in mining, oil and gas, and aquaculture industries. |

Installation | Geotextiles are typically installed as part of a layered system or embedded within soil. | Geomembranes are installed as a standalone liner, often requiring specialized welding techniques for seaming. |

3.How To Choose Geomembranes and Geotextiles In Different Applications?

When choosing between geotextiles and geomembranes for different applications, several factors need to be considered. Here's a general guideline for selecting the appropriate material:

3.1 Function:Determine the primary function of the material in your application.

Geotextiles are commonly used for separation, filtration, drainage, and soil reinforcement.

Geomembranes are primarily utilized for containment and impermeability purposes.

3.2 Permeability: Evaluate the permeability requirements of your project.

Geotextiles typically have higher permeability, They are commonly used in erosion control applications such as slope stabilization and shoreline protection. They help retain soil particles while allowing water to pass through.

Geomembranes have very low permeability and are used when a high level of containment or impermeability is needed.They are not typically used for erosion control due to their impermeable nature.But this impermeability is one of the key properties that make geomembranes suitable for various applications where containment or barrier functions are required.

3.3 Strength and Stability: Consider the required strength and stability of the material.

Geotextiles provide reinforcement and stabilization to soils.

Geomembranes are generally used as a barrier against water or gases.

3.4 Separation and Stabilization:Compared to the two,Geotextile is the preferred choice.

Geotextiles commonly used to separate different soil layers and provide stabilization. They prevent the mixing of fine and coarse-grained soils, improving overall stability.

Geomembrane Impermeable barriers used for containment applications such as lining ponds, landfills, or reservoirs where fluid migration needs to be prevented.However, geomembranes are less commonly used for separation compared to geotextiles.

3.5 Environmental Compatibility: Assess the compatibility of the material with the surrounding environment.

Geotextiles are often chosen for their ability to promote vegetation growth, erosion control, and long-term sustainability.

Geomembranes may be more suitable for applications where chemical resistance or environmental protection is crucial.Containment of liquids, including ponds, reservoirs, and landfills.

3.6 Installation and Maintenance: Take into account the installation and maintenance requirements.

Geotextiles are typically easier to install, repair, and maintain due to their flexible nature.

Geomembranes require specialized welding or sealing techniques for proper installation and maintenance.

Ultimately, the choice between geomembranes and geotextiles depends on the specific requirements of the application, including separation, filtration, drainage, reinforcement, and environmental considerations etc.

4.Conclusion

Geotextiles and geomembranes are distinct types of geosynthetic materials utilized in geotechnical and civil engineering projects. Each material has unique characteristics, functions, and applications. When deciding between geotextiles and geomembranes, it is crucial to carefully assess the project's specific requirements.

Geotextiles are typically composed of synthetic fibers and are designed to provide filtration, separation, reinforcement, and drainage functions. They are commonly used to enhance soil stability, prevent erosion, and control sedimentation. Geotextiles allow water to pass through while retaining soil particles, making them suitable for applications such as road construction, retaining walls, and erosion control.On the other hand, geomembranes are impermeable liners made from synthetic materials like high-density polyethylene (HDPE), polypropylene (PP), or polyvinyl chloride (PVC). Their primary function is containment, as they prevent the movement of liquids or gases. Geomembranes are used in applications that require fluid barriers, such as landfill liners, water storage reservoirs, and hazardous waste containment.

5.About GEOSINCERE

GEOSINCERE is always committed to geomembrane research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembranes and geotextiles for civil, mining, environmental and aquaculture engineering applications. We have been exporting geomembranes and geosynthetics to over 60 countries such as Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, etc.

Quality assurance, factory price and fast delivery time are our competitive advantages.Hope to be your partner.