What Are the Key Applications of Geomembrana 1mm in Waste Management?

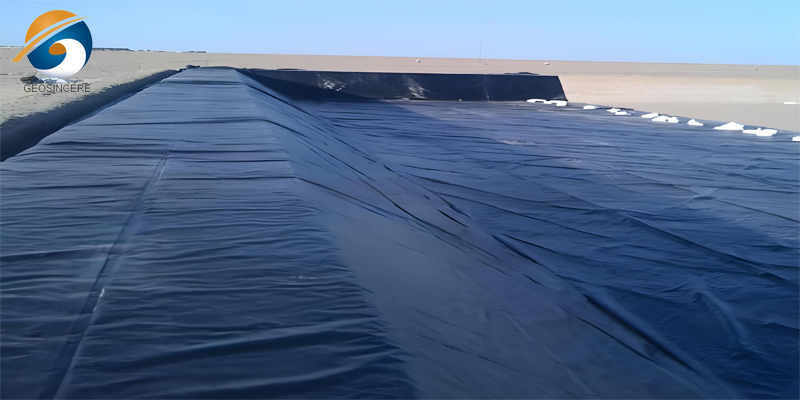

In the realm of waste management, the pursuit of sustainable and superior options has never been more critical. As the global focus shifts towards environmental protection and eco-friendly waste treatment, this ultra-thin yet highly durable fabric has made significant progress in revolutionizing waste control and management practices. But what exactly are the key applications of geomembrana 1mm in waste management, and how does its unique combination of strength and flexibility contribute to a more sustainable future?

From landfill liners to hazardous waste containment, geomembrana 1mm has proven to be a vital asset in modern waste management strategies. Its ability to provide a robust barrier against seepage and contamination, while being cost-effective and easy to install, makes it an ideal choice for a wide range of applications. This article will explore the key applications of geomembrana 1mm in waste management, highlighting its benefits and crucial role in protecting ecological integrity.

1. How Does Geomembrana 1mm Compare to Other Liner Materials?

When deciding on the appropriate liner for waste management and containment applications, geomembrana 1mm is a versatile and highly efficient choice. But how does it measure up against different standards and industrial-grade liner materials? Let’s uncover the key differences and advantages of using geomembrana 1mm compared to options like clay, concrete, and various polymer liners.

1.1 Impermeability and Chemical Resistance

One of the most critical properties of any liner material is its ability to prevent leakage and withstand chemical exposure. Geomembrana 1mm, primarily made from high-density polyethylene (HDPE), offers exceptional impermeability with a permeability coefficient below 10^-14 m/s. This makes it a superior choice over materials like compacted clay, which can crack and shrink over time, allowing seepage. Additionally, HDPE geomembranes exhibit excellent resistance to a wide range of chemicals, making them ideal for applications involving aggressive acidic, alkaline, or organic media. In contrast, clay and concrete are more susceptible to chemical erosion and acid attack.

1.2 Durability and Longevity

Geomembrana 1mm liners, especially those made from HDPE, are renowned for their long-term durability. Properly installed HDPE geomembranes can have a service life exceeding 50-100 years. They are UV-resistant, flexible across a broad temperature range, and can withstand harsh environmental conditions without degrading. This is a significant improvement over materials like PVC, which are more prone to UV degradation. Concrete, while rigid and durable, can crack due to temperature changes, chemical attack, or settling, reducing its effectiveness over time.

1.3 Cost-Effectiveness and Installation

From a cost perspective, geomembrana 1mm offers substantial advantages. HDPE geomembranes are lightweight, reducing transportation costs, and can be pre-fabricated to specific dimensions, simplifying the installation process. Compared to clay or concrete, which require extensive site preparation and skilled labor, their installation is far less complex. The ability to weld sections into large, continuous sheets with minimal seams also reduces the risk of leakage and installation time.

1.4 Mechanical Properties

Geomembrana 1mm liners exhibit top-tier mechanical properties, including high tensile strength, tear resistance, and puncture resistance. For example, a 1mm HDPE geomembrane has a tensile strength at break of at least 27 N/mm-width and a puncture resistance of at least 320 N. These properties make it highly resilient against mechanical stress and environmental factors, unlike clay liners, which are particularly prone to punctures and cracks.

1.5 Versatility and Application Scope

Geomembrana 1mm is incredibly versatile, making it suitable for a wide range of applications, from landfill liners and wastewater ponds to industrial waste containment and mining operations. Its flexibility and adaptability to different terrains and climates further enhance its usability. In contrast, conventional materials like clay and concrete are more rigid and have far less adaptability to ground movement.

2. What Specific Types of Landfills Use Geomembrana 1mm?

2.1 Municipal Solid Waste (MSW) Landfills

Municipal solid waste landfills are designed to contain everyday household and commercial waste. Geomembrana 1mm is used as a primary liner to prevent leachate (the liquid that forms as waste decomposes) from contaminating the soil and groundwater. This liner acts as a robust barrier, ensuring that harmful substances do not seep into the environment.

2.2 Hazardous Waste Landfills

Hazardous waste landfills require highly durable and impermeable materials to safely contain toxic and corrosive substances. 1mm geomembrana, particularly made from HDPE (High-Density Polyethylene), is ideal for this purpose due to its superior chemical resistance and long-term durability. It prevents hazardous materials from leaking into the surrounding soil and water, ensuring environmental safety.

2.3 Industrial Waste Landfills

Industrial waste landfills handle a wide range of waste materials from manufacturing processes. Geomembrana 1mm is used to line these landfills, providing a strong barrier against industrial pollutants. Its high tensile strength and puncture resistance make it suitable for containing sharp and abrasive waste materials.

2.4 Construction and Demolition (C&D) Waste Landfills

Landfills designated for construction and demolition waste often contain heavy and bulky materials. geomembrana 1mm liners are used to prevent the leachate from these landfills from contaminating the environment. The flexibility and adaptability of HDPE geomembranes allow them to conform to the contours of the landfill site, ensuring a secure fit.

2.5 Mining Waste Landfills

In mining operations, geomembrana 1mm is used for the containment of tailings (the waste material left after the extraction of valuable minerals). These liners prevent the release of pollutants into the soil and water, ensuring the safety and integrity of the mining site. HDPE geomembranes are particularly effective due to their resistance to UV degradation and ability to withstand harsh environmental conditions.

2.6 Leachate Collection Systems

Leachate collection systems in landfills require a reliable barrier to prevent the liquid from seeping into the ground. geomembrana 1mm is used to line the bottom and sides of these systems, ensuring that leachate is collected and managed safely. This helps in reducing the risk of groundwater contamination.

Key Advantages of Using Geomembrana 1mm in Landfills

- Impermeability: Prevents liquids and contaminants from seeping into the soil and groundwater.

- Chemical Resistance: HDPE geomembranes can withstand exposure to a wide range of chemicals found in landfill environments.

- Durability and Longevity: HDPE liners are known for their long-term durability, with a service life exceeding 50-100 years.

- Flexibility and Ease of Installation: HDPE geomembranes are flexible and can conform to the contours of the landfill site, making installation easier.

- Cost-Effectiveness: While the initial cost may be higher than other materials, the long-term durability and effectiveness make it a cost-effective solution.

3. Conclusion

Geomembrana 1mm is a highly effective and versatile material used in various types of landfills, from municipal waste to hazardous waste containment. Its excellent impermeability, chemical resistance, and durability make it an ideal choice for preventing environmental contamination and ensuring long-term reliability. Whether used in MSW landfills, hazardous waste sites, or mining operations, 1mm geomembrana plays a crucial role in protecting ecosystems and public health.