What Is the Application Effect of HDPE Plastic Liner in Mining?

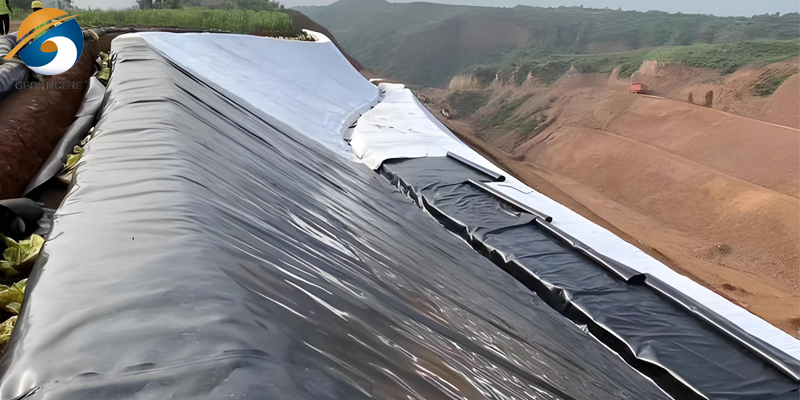

HDPE plastic liner has become an important component of the mining industry and an effective barrier to improve environmental protection and operational efficiency. With its high durability and impermeability, HDPE liner plays a crucial role in managing waste, preventing pollution, and ensuring compliance with environmental regulations.

With the continuous expansion of mining operations, the importance of sustainable practices is increasing, and the use of HDPE liner is not only a regulatory requirement, but also a strategic advantage. In this article, we will explore the specific applications of HDPE plastic liners in mining, their benefits, and their overall impact on optimizing resource management while protecting the environment. Let's delve into the effectiveness of HDPE liner and its key role in modern mining practices!

1. What is HDPE Plastic Liner?

HDPE (High-Density Polyethylene) plastic liner is a durable and versatile material commonly used in various industrial applications, particularly for containment and protection purposes. Made from high-density polyethylene resin, these liners are known for their excellent resistance to chemicals, punctures, and UV radiation, making them suitable for harsh environments. Their impermeability allows them to effectively prevent the leakage of liquids and contaminants, which is crucial for protecting the environment, especially in mining, landfill, and wastewater management applications. The flexibility and strength of HDPE liners enable them to adapt to different shapes and surfaces, ensuring reliable performance in a variety of settings.

2. How Does HDPE Plastic Liner Enhance Tailings Management in Mining?

HDPE plastic liners play a crucial role in improving tailings management in mining operations. By serving as effective barriers, these liners help mitigate environmental impacts and enhance operational efficiency. Here are several ways in which HDPE liners contribute to better tailings management:

2.1 Contamination Prevention: HDPE liners are impermeable, which means they effectively prevent the seepage of tailings and associated contaminants into the surrounding soil and groundwater. This containment is vital for protecting nearby ecosystems and water resources.

2.2 Stability and Support: The use of HDPE liners in tailings storage facilities helps stabilize the structure. They provide a solid foundation that minimizes the risk of tailings dam failures, which can have catastrophic environmental consequences.

2.3 Leachate Control: HDPE liners help manage leachate, the liquid that can percolate through tailings and carry pollutants. By containing leachate within designated areas, these liners facilitate proper treatment and disposal, reducing the risk of environmental contamination.

2.4 Cost-Effectiveness: Implementing HDPE liners can lead to long-term cost savings by reducing the need for remediation efforts associated with contaminated sites. By preventing leaks and spills, mining companies can avoid costly fines and cleanup operations.

2.5 Regulatory Compliance: Many jurisdictions require strict environmental protections for tailings management. HDPE liners help mining companies comply with these regulations, ensuring that they meet the necessary standards for environmental safety.

2.6 Operational Efficiency: By providing a reliable containment solution, HDPE liners allow for more efficient management of tailings. This includes easier access for monitoring and maintenance, as well as improved planning for future tailings storage.

2.7 Environmental Protection: The use of HDPE liners aligns with sustainable mining practices. By minimizing environmental impacts and protecting water resources, these liners contribute to a more responsible approach to resource extraction.

In summary, HDPE plastic liners significantly enhance tailings management in mining by preventing contamination, stabilizing structures, controlling leachate, and ensuring compliance with environmental regulations. Their effectiveness not only protects the environment but also supports the long-term sustainability of mining operations.

3. How to Install HDPE Plastic Liner in Mining Sites?

3.1 Site Preparation

- Survey the Area: Assess the site to determine the specific areas that require lining.

- Clear the Ground: Remove any vegetation, rocks, and debris from the area where the liner will be installed.

- Grade the Surface: Ensure the ground is smooth and free of sharp objects that could puncture the liner.

3.2 Select the Liner

- Choose the appropriate thickness and type of HDPE liner based on the site’s requirements (typically 30-60 mil is common for mining applications).

3.3 Cutting the Liner

- Measure the Area: Measure the dimensions of the area to be lined.

- Cut the Liner: Use a utility knife to cut the HDPE liner to the required dimensions, allowing for overlaps and seams.

3.4 Laying the Liner

- Position the Liner: Lay the HDPE liner over the prepared surface, ensuring it fits snugly. For large areas, consider using multiple sheets.

- Overlap the Seams: Ensure that seams overlap by at least 12 inches to prevent leakage.

3.5 Securing the Liner

- Stake Down the Liner: Use stakes or sandbags to hold the liner in place, especially in windy conditions.

- Anchor the Edges: Use soil or gravel to anchor the edges of the liner to prevent movement.

3.6 Seaming the Liner

- Weld the Seams: Use a fusion welding machine for HDPE to join the seams. Ensure that the welding is done according to manufacturer specifications for strength and durability.

- Check for Leaks: Perform a pressure test to ensure that all seams are secure and leak-proof.

3.7 Backfilling

- Cover the Liner: Once installation and testing are complete, backfill with soil or gravel as needed to protect the liner from UV exposure and physical damage.

3.8 Final Inspection

- Inspect the Installation: Conduct a thorough inspection of the liner and seams to ensure proper installation.

- Document the Process: Keep records of the installation for future reference and environmental compliance.

4. Summarize

The application effect of HDPE plastic lining in mining process is significant. They effectively prevent the infiltration of harmful substances, protect soil and groundwater, and reduce environmental pollution risks. Chemical resistance and durability enhance the safety of tailings management and improve the stability of tailings ponds.