Is Prefabricated Geomembrane Waterproof?

Prefabricated geomembranes are engineered materials designed to provide high-quality barriers against water and various fluids. Their primary purpose is to prevent leakage and contamination in numerous applications, such as landfills, wastewater treatment facilities, and irrigation systems. This waterproof performance is essential for protecting the surrounding environment and maintaining the integrity of containment systems.

In this article, we will explore the waterproof characteristics of prefabricated geomembranes, the materials used in their production, and the inspection strategies considered to evaluate their effectiveness. By understanding these aspects, we can appreciate the crucial role these liners play in sustainable development and environmental protection.

1. What Is Prefabricated Geomembrane?

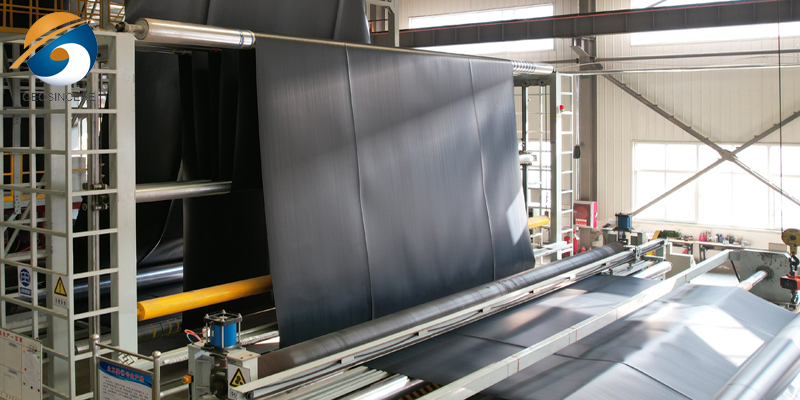

A prefabricated geomembrane is a synthetic membrane made from durable materials designed to serve as a barrier against water and other fluids. These geomembranes are manufactured off-site and then transported to the installation location, where they are deployed for various applications.

1.1 Key Characteristics

- Material Composition: Common materials include High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), and Ethylene Propylene Diene Monomer (EPDM). These materials provide excellent resistance to chemical and environmental factors.

- Seamless Installation: Prefabricated geomembranes are often produced in large sheets, which minimizes seams and potential leak points during installation.

- Durability: They are designed to withstand harsh environmental conditions, including UV radiation, extreme temperatures, and soil movement.

- Flexibility: These geomembranes can conform to various shapes and surfaces, making them suitable for diverse applications.

1.2 Applications

- Landfills: To contain leachate and prevent groundwater contamination.

- Water Reservoirs: To prevent water loss and maintain quality.

- Wastewater Treatment: To create impermeable barriers in treatment ponds.

- Irrigation Systems: To protect water resources from contamination.

1.3 Benefits

- Environmental Protection: Helps prevent leakage and contamination, safeguarding ecosystems.

- Cost-Effective: Reduces the need for extensive maintenance and repairs over time.

- Ease of Installation: Streamlined processes can save time and labor costs during deployment.

2. Installation Techniques for Prefabricated Geomembrane

2.1 Site Preparation

- Clearing and Grading: Remove debris, sharp objects, and vegetation. Grade the floor for desirable drainage and a clean foundation.

- Subgrade Inspection: Ensure the subgrade is steady and compact to stop deformation.

2.2 Laying Out the Geomembrane

- Alignment: Position geomembrane liner in accordance to format specifications.

- Overlapping: Overlap seams accurately to create a non-stop barrier.

2.3 Seaming Techniques

- Heat Welding: Common technique the place edges are heated and pressed collectively for a watertight bond.

- Extrusion Welding: A welding rod is melted into seams for brought durability.

- Adhesive Bonding: Adhesives may additionally be used for sure substances like PVC.

2.4 Anchor and Secure

- Ballast: Use soil or gravel to maintain the geomembrane in place.

- Mechanical Anchors: Secure edges to forestall movement, particularly in windy areas.

2.5 Testing and Quality Control

- Visual Inspection: Check for defects and wrong seams post-installation.

- Non-Destructive Testing: Use vacuum or air stress assessments to make certain seam integrity.

2.6 Backfilling and Covering

- Cover the geomembrane with soil or different substances cautiously to keep away from damage.

2.7 Final Inspection

- Conduct a final check to ensure all specifications are met for optimal performance.

3. Testing Methods for Evaluating Waterproof Properties Geomembrane

3.1 Hydraulic Conductivity Test

Let's take a look at the permeability of geomembrane materials. It usually involves placing the fabric in water below the management pressure and measuring the flow rate. Low hydraulic conductivity indicates appropriate waterproof ability.

3.2 Leak Detection Tests

-Leakage location investigation (ELLS): This method uses current to detect leaks in geomembranes. By applying current, any damage to the lining will cause the current to escape, indicating the presence of leakage.

-Vacuum testing: Vacuum treatment is applied to the geomembrane, and any decrease in strain indicates the presence of feasible leakage.

3.3 Puncture Resistance Test

This evaluates the potential of the geomembrane to puncture, which may impair its waterproof performance. Apply a certain weight to the material and measure the pressure required to pierce through it.

3.4 Tensile strength test

This technology evaluates the strength and robustness of geomembranes. A pattern will be affected by anxiety until it fails and the maximum load is recorded. Stronger materials are less likely to cause tearing or holes, leading to leakage.

3.5 UV resistance test

Due to the frequent exposure of geomembranes to sunlight, let's take a look at their resistance to ultraviolet (UV) radiation. The sample is exposed to ultraviolet radiation for a specific period of time and any degradation of the fabric is evaluated.

3.6 Chemical Resistance Test

Geomembranes may also be exposed to various chemicals, especially in industrial applications. This inspection requires immersing the sample in a specific chemical substance for a certain length and evaluating any adjustments to weight, appearance, or mechanical properties.

3.7 Thermal Stability Test

This will evaluate the overall performance of the geomembrane under improved temperature conditions. The sample is subjected to excessively high temperatures to consider its size balance and deformation feasibility.

4. Conclusion

Prefabricated geomembranes are indeed waterproof, making them essential components in various civil engineering and environmental applications. Their ability to prevent leakage and contamination plays a vital role in protecting natural resources and promoting sustainable practices.