How to Choose The Thickness of Geomembrane?

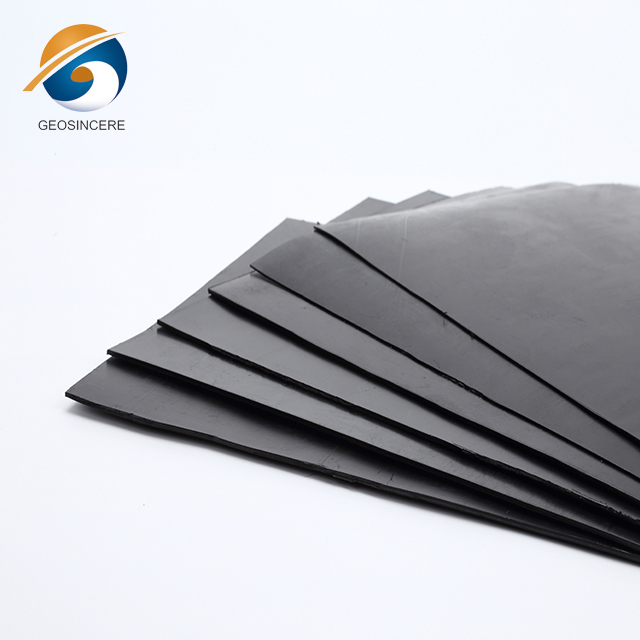

Geomembranes are an essential component in various civil engineering and environmental projects, providing a barrier against fluid or gas migration. Geomembranes are synthetic liners made from reinforced polymeric materials that have excellent impermeability. They are designed to have high tensile strength, durability, and chemical resistance, making them ideal for a wide range of environmental and geotechnical applications. Selecting the appropriate thickness of geomembrane is crucial to ensure the long-term effectiveness and durability of the installation.

Geomembranes are typically manufactured as sheets with thicknesses ranging from 20 mils to 120 mils or 0.5 mm to 3 mm.Choosing the appropriate geomembrane thickness involves considering various factors, including engineering requirements, site conditions, and design parameters.

Here are some key factors to consider when choosing the thickness of geomembrane for your specific application.Let's explore together how to choose the thickness of geomembrane?

1. Engineering Requirements

To meet engineering requirements, the first step is to identify the main functions and specific needs of the geomembrane. Geomembranes are versatile and can serve purposes such as anti-seepage, protection, and separation. Once the primary function is determined, the selection of the appropriate type and corresponding thickness of geotextile becomes essential.

1.1 Anti-Seepage Function

If the primary goal is to prevent seepage or fluid migration, the geomembrane's impermeability is critical. Choosing a geomembrane with a thickness that offers the desired impermeability is crucial. Thicker geomembranes generally provide lower permeability and can be more effective in preventing seepage.

1.2 Protection Function

If the geomembrane is intended to protect underlying materials or structures, such as liners for landfills or reservoirs, the selection of thickness should be based on the potential risks of puncture or damage. Thicker geomembranes can provide improved resistance against sharp objects, equipment, or environmental elements, offering better protection.

1.3 Separation Layer

Such as in road construction or pond lining, the selection of thickness should ensure effective separation between different layers of materials. Thicker geomembranes can provide better integrity and separation performance.

2. Site Conditions

The geological, soil, and hydrological conditions of the site should be carefully evaluated when selecting the geomembrane thickness. If the groundwater level is high or the soil permeability is strong, it may be necessary to choose a thicker geomembrane to ensure the anti-seepage effect. Geological conditions also have an impact on the selection of geomembranes, for example, areas with frequent geological activities may require more durable and flexible geomembranes.

2.1 Groundwater Level

If the groundwater level is high, there is an increased risk of water pressure and potential seepage. In such cases, selecting a thicker geomembrane can help ensure effective anti-seepage performance and prevent water migration through the liner.

2.2 Soil Permeability

The permeability of the soil is an important consideration. If the soil has a strong permeability or is prone to preferential flow paths, a thicker geomembrane may be necessary to provide a more robust barrier against seepage.

2.3 Geological Activity

Sites that experience frequent geological activities, such as earthquakes or ground movements, require geomembranes that can withstand such conditions. Thicker geomembranes with enhanced durability and flexibility can be chosen to accommodate potential ground shifts and maintain the integrity of the liner system.

3. Environmental Conditions

Evaluating the environmental conditions at the site is crucial to determine the required geomembrane thickness, including temperature variations, UV exposure, and chemical compatibility. Some geomembranes may require additional thickness to withstand extreme temperatures or prolonged exposure to sunlight. Chemical exposure, such as acidic or alkaline environments, may also require thicker geomembranes with enhanced chemical resistance.

3.1 Temperature Variations

Extreme temperature variations can affect the performance and longevity of geomembranes. In regions with significant temperature fluctuations, thicker geomembranes may be necessary to withstand thermal expansion and contraction without compromising their integrity.

3.2 UV Exposure

Prolonged exposure to sunlight and UV radiation can degrade geomembranes over time. Thicker geomembranes often offer better UV resistance and can provide extended service life in areas with high sun exposure.

3.3 Chemical Compatibility

If the site involves exposure to chemicals, such as acidic or alkaline environments, it is important to select geomembranes with appropriate chemical resistance. Thicker geomembranes with enhanced chemical resistance properties can provide better protection against chemical degradation and ensure long-term performance.

4. Function and Application

Identify the primary function of the geomembrane in your project. Whether it is for containment, lining, or capping, the intended purpose will influence the required thickness. For example, a geomembrane used for hazardous waste containment may require a thicker membrane compared to a simple decorative pond liner.

4.1 Containment

If the geomembrane is intended for containment purposes, such as storing hazardous waste or preventing contamination of soil and groundwater, a thicker membrane is often necessary. A thicker geomembrane provides a more robust barrier against leaks and ensures the integrity of the containment system.

4.2 Lining

In applications where the geomembrane is used for lining, such as in ponds, reservoirs, or canals, the required thickness may vary depending on factors like water pressure, soil conditions, and potential puncture risks. Thicker geomembranes can provide added protection against punctures and improve the overall durability of the lining system.

4.3 Capping

When using a geomembrane for capping landfills or other waste disposal sites, the thickness should be determined based on the desired level of impermeability and the potential for gas or leachate migration. Thicker geomembranes can enhance the effectiveness of the cap by reducing the risk of contaminant release.

5. Cost Considerations

Cost considerations are an important aspect when selecting the appropriate geomembrane thickness.Geomembrane thickness can influence the overall project cost. Thicker geomembranes are generally more expensive, but they may provide long-term cost savings by reducing the risk of leakage or premature failure. Consider the trade-offs between initial cost and long-term performance when selecting the thickness.

Thin geomembranes are relatively soft and flexible, making them easier to adapt to uneven terrain and changes in terrain. This makes them easier to operate and install during the construction process. In addition, thin geomembranes are usually easier to bend and fold than thick geomembranes, making them easier to customize and adjust on the construction site.

Thicker geomembranes often provide enhanced durability, resistance to punctures, and lower permeability, which can reduce the risk of leakage or premature failure. This can result in long-term cost savings by minimizing the need for repairs, maintenance, or early replacement. Additionally, thicker geomembranes may offer extended service life, reducing the frequency of replacements or interventions.

6.Conclusion:

Selecting the appropriate thickness of geomembrane is a critical decision that can significantly impact the success of your project. By considering the environmental conditions, design life, function, substrate conditions, hydraulic considerations, engineering standards, cost implications, and seeking expert advice, you can make an informed choice that ensures the effectiveness and longevity of your geomembrane installation.